Abstract

This study investigates the casting process design for a large ductile iron bearing cover used in diesel engines. The bearing cover, as a critical component supporting the crankshaft, must possess high mechanical integrity to withstand cyclic loading. This paper focuses on addressing the common issues of shrinkage porosity and slag inclusion encountered during the casting process. By introducing built-in sand cores, cold iron, adjusting material composition, and designing an efficient filter slag removal system, the study aims to eliminate defects, improve casting yield, and reduce processing costs.

Introduction

Bearing covers play a vital role in diesel engines by supporting and positioning the crankshaft, ensuring smooth and efficient engine operation. Due to their strategic location and function, bearing covers are subjected to severe mechanical stress and must meet stringent quality standards. This study focuses on the casting process design of a large ductile iron bearing cover, specifically addressing challenges such as shrinkage porosity and slag inclusion.

Material and Methods

1. Material Selection

The bearing cover is made from QT400-15 ductile iron, chosen for its excellent mechanical properties, including high strength, ductility, and wear resistance. QT400-15 is a nodular cast iron with spheroidal graphite, providing an optimal balance between strength and toughness.

2. Casting Process Design

The casting process design involved several key steps, including mold preparation, gating system layout, cooling system design, and defect prevention measures.

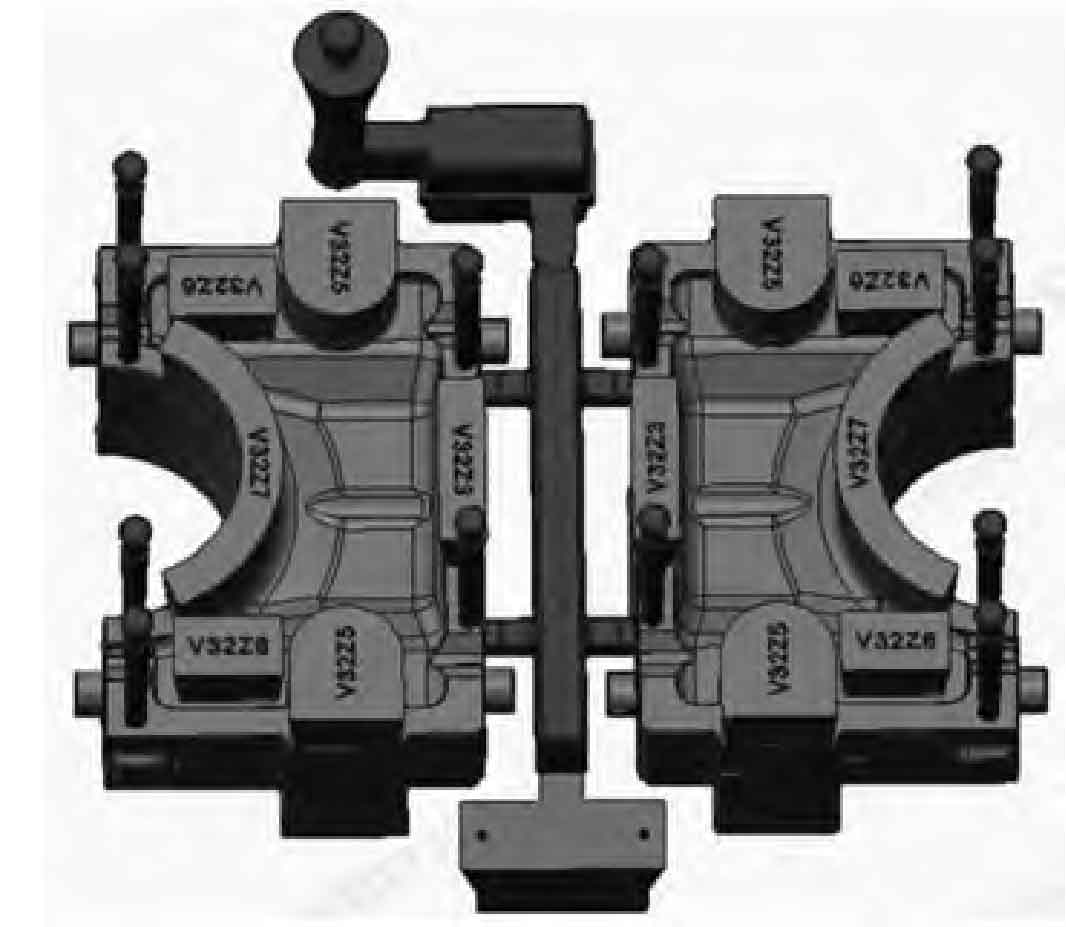

2.1 Mold Preparation

The mold was prepared using high-quality sand with appropriate binders to ensure dimensional accuracy and surface finish. The mold design incorporated features to facilitate the placement of sand cores and cold iron, as well as the positioning of the gating system.

2.2 Gating System Layout

The gating system was designed to ensure smooth and even flow of molten iron into the mold cavity, minimizing turbulence and entrainment of impurities. The system comprised a sprue, runner, and ingate, strategically positioned to optimize filling and promote directional solidification.

2.3 Cooling System Design

An efficient cooling system was implemented using chill plates and cold iron inserts to accelerate the solidification process and minimize shrinkage porosity. The cold iron was strategically placed in hotspots to promote uniform cooling and prevent the formation of defects.

3. Defect Prevention Measures

3.1 Built-in Sand Cores

To reduce the formation of hotspots and shrinkage porosity, built-in sand cores were integrated into the casting design. These cores provided structural support during the casting process and facilitated the creation of complex internal features such as bolt holes.

3.2 Cold Iron Inserts

Cold iron inserts were strategically positioned in critical areas prone to hotspots and shrinkage porosity. The cold iron accelerated local cooling rates, promoting directional solidification and minimizing the formation of defects.

3.3 Filter Slag Removal System

An efficient filter slag removal system was designed to prevent the entrainment of impurities during the pouring process. The system comprised ceramic filter plates strategically positioned in the gating system to trap and remove slag and other contaminants.

4. Experimental Setup

To validate the effectiveness of the casting process design, a series of experimental casts were produced under controlled conditions. The casts underwent rigorous inspection, including visual inspection, radiographic testing, and metallographic analysis to identify and quantify defects.

Results and Discussion

1. Defect Analysis

Initial casts produced using the original casting process design exhibited significant shrinkage porosity and slag inclusion defects. These defects were primarily localized in hotspots, particularly around the bolt holes and thick sections of the bearing cover.

1.1 Shrinkage Porosity

Shrinkage porosity is a common defect in cast iron components, particularly in thick sections where solidification occurs more slowly. In the initial casts, shrinkage porosity was observed in the bolt hole regions and adjacent thick sections.

1.2 Slag Inclusion

Slag inclusion defects were also prevalent in the initial casts, particularly in areas where the flow of molten iron was turbulent. These defects compromised the mechanical integrity of the bearing cover and increased the risk of failure under loading .

2. Improved Casting Process Design

The introduction of built-in sand cores, cold iron inserts, and an efficient filter slag removal system significantly reduced defect formation in subsequent casts.

2.1 Built-in Sand Cores

The integration of built-in sand cores reduced hotspots by providing structural support during the casting process. This led to a more uniform solidification pattern and minimized the formation of shrinkage porosity .

2.2 Cold Iron Inserts

The strategic placement of cold iron inserts accelerated local cooling rates and promoted directional solidification. This effectively minimized the formation of shrinkage porosity in critical areas.

2.3 Filter Slag Removal System

The efficient filter slag removal system significantly reduced the entrainment of impurities during the pouring process. This led to cleaner casts with minimal slag inclusion defects .

3. Yield and Cost Analysis

The improved casting process design led to a significant increase in casting yield and a reduction in processing costs. The yield rate improved from 56% to 82%, translating to substantial savings in material and labor costs.

Conclusion

This study successfully addressed the challenges of shrinkage porosity and slag inclusion in the casting process design of a large ductile iron bearing cover. By incorporating built-in sand cores, cold iron inserts, and an efficient filter slag removal system, the study demonstrated a marked improvement in casting quality and yield. The results of this study have significant implications for the production of high-quality ductile iron components in the automotive and heavy engineering sectors.