Abstract:

This comprehensive article delves into the intricacies of gas hole and shrinking defects in large QT400-15 tray castings, which are crucial components in coal milling equipment. It introduces the structure and technical specifications of ductile iron tray castings, elaborates on the original production process, and identifies the primary locations and characteristics of porosity and shrinkage. Through meticulous analysis, the article uncovers the root causes of these defects: excessive moisture in the mold leading to invasive porosity and improper use of cold iron resulting in shrinkage. A series of targeted prevention measures are then proposed and validated, including reducing moisture content, improving mold permeability, optimizing cold iron placement, enhancing liquid feeding by increasing riser size, and boosting self-feeding ability by adjusting the carbon content of molten iron. These measures have successfully eliminated porosity and shrinking defects in the tray castings, ensuring the stable production of high-quality QT400-15 ductile iron castings.

1. Introduction

Coal milling equipment, such as ball mills, plays a vital role in industries like power generation, metallurgy, and chemicals. The tray, as an integral part of the coal milling process, collaborates with the driving disk to rotate and grind coal blocks into fine powder, enhancing combustion efficiency. Due to the high torsion and impact vibration loads it bears, the tray casting demands high strength, toughness, and plasticity, making QT400-15 material the preferred choice. However, tray castings often suffer from porosity and shrinkage defects, particularly at the circular “L”-shaped corners, which can lead to casting rejection.

This article analyzes the causes of porosity and shrinkage defects in QT400-15 tray castings, explores countermeasures, and aims to prevent the recurrence of such defects, ensuring the quality of tray castings as functional components of coal milling equipment.

2. Structure and Technical Requirements of Tray Castings

2.1 Structure of Tray Castings

The tray is a large circular casting with a unique structural design. The cross-sectional structure of the casting. The outer diameter of the casting ranges from 3,090 mm to 5,000 mm, with a height of 370 mm and a gross weight between 5.1 and 9 tons. The minimum wall thickness is 55 mm, while the peripheral wall thickness is 80-100 mm. Notably, the “L”-shaped corner feature results in uneven wall thickness and inadequate ventilation, increasing the susceptibility to porosity and shrinkage defects.

2.2 Technical Requirements

The tray casting must meet stringent technical specifications. The tensile strength of the separately cast test specimen should be ≥400 MPa, with an elongation after fracture ≥15%. For the attached test specimen, the tensile strength should be ≥370 MPa, and the elongation after fracture should be ≥11%.

3. Casting Process of Tray Castings

3.1 Casting Technique

The casting process utilizes furan resin sand molding. The largest diameter surface serves as the parting plane, with the outer contour formed by the sand box and the inner contour by the sand core. The sand core consists of two parts: a ring-shaped core and a cylindrical core. A bottom-gating pouring system ensures pouring speed and slag retention, with a gating ratio (ΣS direct: ΣS transverse: ΣS internal) of 1.21:1.63:1.

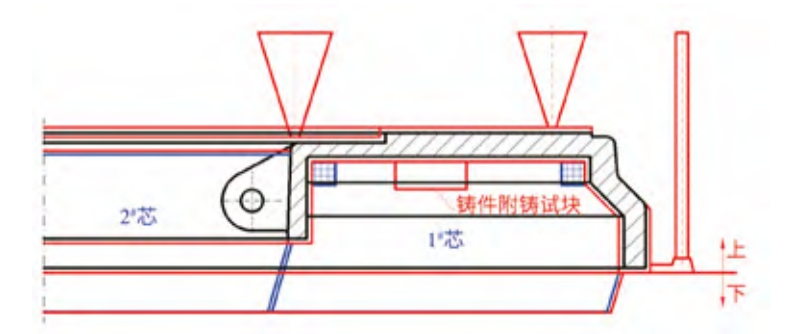

Given its ductile iron composition, to exploit the graphitization expansion, a riser with a lower section of 20 mm × 50 mm and an upper section of 80 mm × 150 mm is placed at the thick section. Dark chill is positioned around the ring core to assist in cooling, ensuring casting density. The attached test specimen has dimensions of 180 mm × 70 mm × 70 mm. The process diagram of the casting.

3.2 Melting Process

Melting is conducted in a 20-ton medium-frequency induction furnace. Raw materials include scrap steel, Q10 pig iron, 93% carburant, 90% silicon carbide, 75% ferrosilicon, and 65% ferromanganese. The superheat temperature ranges from 1,500 to 1,520°C, while the nodularizing temperature is maintained between 1,450 and 1,480°C. The pouring temperature is controlled at 1,350 to 1,370°C, followed by a cooling period of 60 hours before the mold is opened. The charge mix consists of 60% scrap steel and 40% pig iron, with specific chemical composition control ranges as outlined in Table 1.

Table 1 Chemical Composition of Trays

| Element | Range |

|---|---|

| C | 3.50~3.80 |

| Si | 2.2~2.7 |

| Mn | ≤0.4 |

| P | ≤0.05 |

| S | ≤0.020 |

| Mg | 0.03~0.06 |

The nodularization process employs the pour-over method, with a nodulizer addition rate of 1.1% to 1.3%. The inoculant used is a combination of silicon-barium and ferrosilicon, with a total inoculant addition rate of 0.8% to 1.2%. This melting process ensures the production of high-quality ductile iron with the desired mechanical properties for the tray castings.