Abstract

Valve shell steel castings, which are pressure vessels operating under high temperature and high strength, are generally formed by casting. This paper analyzes the typical defects of valve shell steel castings and identifies the root causes of core instability and insufficient core bone stiffness during the molding process. A new design method for double core bones is proposed. By combining various measures such as lower core standard core, closing and checking the box, and reverse deformation, the problem of core drifting in valve shell steel castings is solved, thus improving product quality and yield.

1. Introduction

Valve shell steel castings are widely used in various industries due to their high strength, high temperature resistance, and good sealing performance. However, during the casting process, these castings often face challenges such as core drifting, which leads to dimensional deviations, porosity, and other defects. To address these issues, a comprehensive study on the anti-floating core technology for valve shell steel castings was conducted.

This paper first analyzes the forming process and typical defects of valve shell steel castings. Then, specific improvement measures are proposed, including the design of double core bones, core head fixation, core head gap inspection, and reverse deformation. Finally, the effectiveness of these measures is verified through practical applications.

2. Forming Process and Typical Defects of Valve Shell Steel Castings

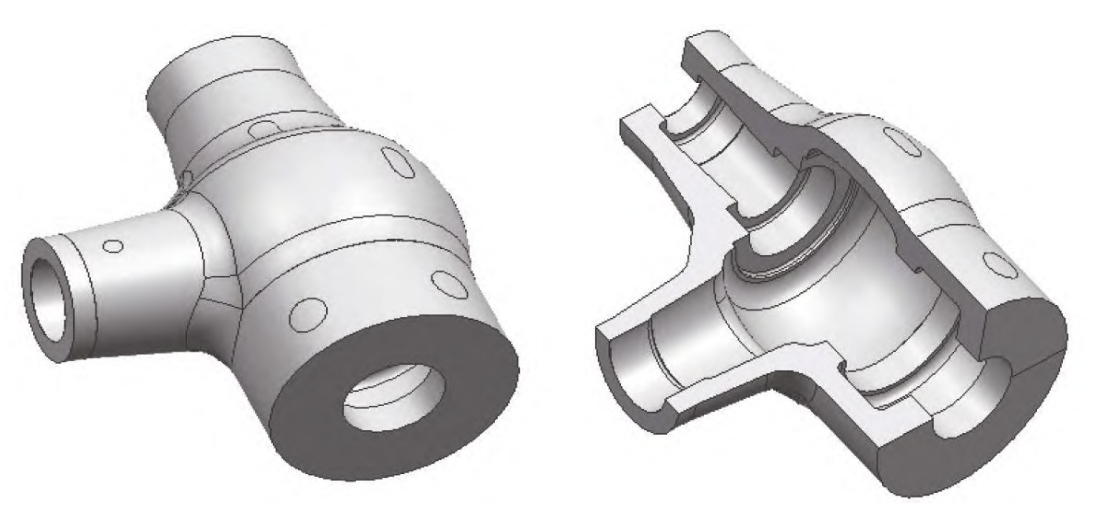

2.1 Forming Process of Valve Shell Steel Castings

Valve shell steel castings are generally produced using the casting method. For example, the production process of a large main steam valve shell casting in a steel castings manufacturer involves the following steps:

- Sand Core Preparation: The internal cavity of the valve shell is formed by a sand core. The sand core is positioned through core heads at both ends of the nozzle to form the casting cavity.

- Molding: The molding method adopts a two-box molding structure, with the casting lying flat to facilitate sand core support and feeding of the casting. The sand core is positioned and cooperates with the upper and lower molds to form the casting cavity.

- Pouring: Molten steel is poured into the mold cavity to form the valve shell steel casting.

2.2 Typical Defects of Valve Shell Steel Castings

During the production process of valve shell steel castings, the following typical defects may occur:

- Dimensional Deviation: Mainly manifested as the wall thickness of the internal cavity being smaller in the upper part and larger in the lower part, resulting in uneven casting dimensions.

- Porosity: Due to the deviation in wall thickness caused by core drifting, the feeding channel is changed, leading to the formation of porosity defects.

Table 1: Dimensional Analysis of Spherical Wall Thickness of Castings

| Casting | Sand Core Span (L) | Core Bone Diameter | Theoretical Wall Thickness | Actual Measured Wall Thickness (mm) | Core Drifting Amount (mm) |

|---|---|---|---|---|---|

| Valve 1 | 2,700 | 100 | 90 | 75, 78, 81, 90, 98, 105 | 10, 12, 9, 0, 8, 15 |

| Valve 2 | 2,700 | 100 | 90 | 73, 80, 89, 99, 107, 98 | 17, 10, 1, 9, 7, 12 |

| Valve 3 | 2,700 | 100 | 90 | 74, 81, 91, 97, 106, 97 | 16, 9, 1, 3, 6, 13 |

| Valve 4 | 3,590 | 120 | 100 | 77, 87, 99, 110, 122, 110 | 23, 13, 1, 10, 22, 10 |

| Valve 5 | 3,590 | 120 | 100 | 80, 89, 100, 110, 120, 109 | 20, 11, 0, 10, 20, 11 |

| Valve 6 | 3,590 | 120 | 100 | 79, 88, 100, 111, 121, 110 | 21, 12, 0, 11, 21, 10 |

As shown in Table 1, the core drifting amount of the valve shell castings ranges from 10 to 23 mm, which significantly affects the dimensional accuracy of the castings.

3. Causes of Core Drifting in Valve Shell Steel Castings

Core drifting in valve shell steel castings is mainly caused by the following factors:

- Instability of Sand Core: Due to insufficient stiffness of the core bone and the large buoyancy of molten steel, the sand core deforms during pouring, leading to core drifting.

- Molding Process Issues: Problems such as insufficient core head fixation, excessive core head gap, and mold deformation during the molding process increase the risk of core drifting.

4. Improvement Measures for Anti-floating Core

To address the issue of core drifting in valve shell steel castings, the following improvement measures were proposed and implemented:

4.1 Design of Double Core Bones

To improve the stiffness of the sand core, the original single-row core bone was replaced with a double-row core bone design. This design significantly increases the cross-sectional area of the core bone, enhancing its stiffness and stability.

4.2 Core Head Fixation

To ensure the stability of the sand core during the molding process, the core heads were fixed to the lower mold sand. This was achieved by welding core head markers to both the lower mold sand and the core heads.

4.3 Core Head Gap Inspection

To detect any gaps between the core heads and the upper mold, mud strips were laid on the core heads before closing the mold. After closing and then lifting the upper mold, the compaction degree of the mud strips was used to judge the core head gap.

4.4 Reverse Deformation

To compensate for mold deformation, core head gaps, and the buoyancy of molten steel during pouring, a reverse deformation allowance was applied to the inner cavity of the casting during the molding process.

5. Verification of Improvement Measures

After implementing the above improvement measures, the dimensional accuracy and quality of the valve shell steel castings were significantly improved.

Table 2: Comparison of Casting Quality Before and After Improvement

| Item | Before Improvement | After Improvement |

|---|---|---|

| Core Drifting Amount (mm) | 10~25 | 1~3 |

| Porosity Volume (dm³) | 2.5~3 | 0.3~0.5 |

| Welding Repair Rate (dm³/t) | 1.64 | 0.24 |

As shown in Table 2, the core drifting amount was reduced to within 13 mm, and the porosity volume was reduced to 0.30.5 dm³, both meeting customer tolerance requirements. The welding repair rate was also significantly reduced, from 1.64 dm³/t to 0.24 dm³/t.

6. Conclusion

This paper analyzed the typical defects of valve shell steel castings and identified the root causes of core drifting. A new design method for double core bones was proposed, and various measures such as core head fixation, core head gap inspection, and reverse deformation were implemented to effectively control the issue of core drifting. After implementing these measures, the dimensional accuracy and quality of the valve shell steel castings were significantly improved, reducing the welding repair rate and production costs, and shortening the production cycle.

The research results provide valuable reference for steel castings manufacturers to improve the production process and product quality of valve shell steel castings.