1. Introduction

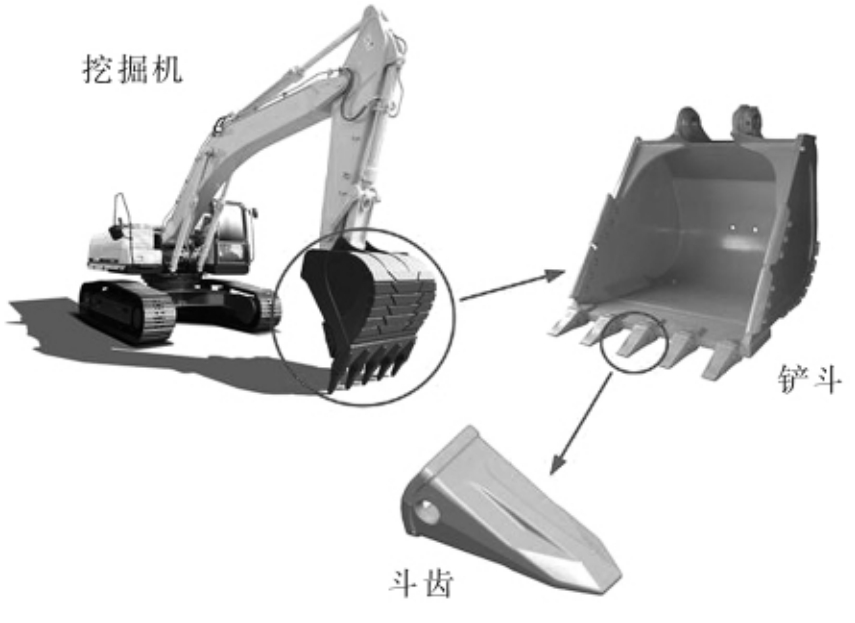

Excavators play a crucial role in various industries such as construction, mining, and infrastructure development. Bucket teeth are essential components of excavators as they directly interact with the materials being excavated. The performance and durability of bucket teeth significantly impact the efficiency and productivity of excavators. Traditional manufacturing processes for bucket teeth often face challenges in meeting the increasing demands for improved mechanical properties and longer service life. Liquid forging technology has emerged as a promising alternative to address these issues.

1.1 The Importance of Bucket Teeth in Excavators

Bucket teeth are subjected to severe working conditions, including high impact forces, abrasive wear, and bending moments. They need to have excellent hardness, wear resistance, and toughness to withstand these harsh environments. The wear and failure of bucket teeth can lead to decreased excavation efficiency, increased maintenance costs, and downtime of the excavator. Therefore, improving the quality and performance of bucket teeth is of great significance for the overall operation of excavators.

1.2 Challenges in Traditional Bucket Teeth Manufacturing Processes

Traditional manufacturing processes for bucket teeth, such as casting and forging, have certain limitations. Casting processes may result in defects such as porosity, shrinkage cavities, and coarse grain structures, which can reduce the mechanical properties of the bucket teeth. Forging processes, on the other hand, require high equipment costs and complex manufacturing procedures, making them less suitable for mass production. Additionally, traditional processes may not be able to achieve the desired combination of hardness and toughness in the bucket teeth, leading to premature wear and failure.

2. Liquid Forging Technology: An Overview

Liquid forging is a metal forming process that combines the advantages of casting and forging. It involves pouring molten metal into a die cavity and applying pressure to the metal during solidification to achieve a dense and defect-free microstructure.

2.1 Principles and Mechanisms of Liquid Forging

The principle of liquid forging is based on the application of pressure to the molten metal during solidification. This pressure helps to eliminate porosity, shrinkage cavities, and other defects in the casting. It also promotes the growth of fine grains, resulting in improved mechanical properties. The pressure applied during liquid forging can be either direct or indirect, depending on the specific process design.

2.2 Advantages of Liquid Forging for Bucket Teeth Manufacturing

Liquid forging offers several advantages for the manufacturing of bucket teeth. Firstly, it can produce bucket teeth with a dense and uniform microstructure, free from defects such as porosity and shrinkage cavities. This leads to improved hardness, wear resistance, and toughness of the bucket teeth. Secondly, liquid forging allows for better control of the grain structure, enabling the production of bucket teeth with a desired combination of mechanical properties. Thirdly, the process is relatively simple and can be easily automated, making it suitable for mass production. Additionally, liquid forging can reduce material waste and energy consumption compared to traditional manufacturing processes.

3. Material Selection and Characterization for Liquid Forged Bucket Teeth

The selection of suitable materials is crucial for the successful application of liquid forging technology in bucket teeth manufacturing. In this study, a low-carbon alloy steel ZG14CrMnSiNi was chosen as the research object.

3.1 Selection Criteria for Bucket Teeth Materials

The selection of bucket teeth materials should consider factors such as hardness, wear resistance, toughness, and cost. The material should have sufficient hardness to resist abrasion and penetration, while also possessing good toughness to withstand impact and bending forces. Additionally, the material should be cost-effective and readily available for mass production.

3.2 Characterization of ZG14CrMnSiNi Steel

The microstructure, hardness, toughness, and other mechanical properties of ZG14CrMnSiNi steel were studied under different pressures. SEM, EDS, and JB – 50 impact testing machine were used for the characterization. The results showed that pressure has a significant impact on the microstructure and mechanical properties of the liquid-forged bucket teeth material. As the pressure increases, the grain size of the steel gradually refines, resulting in improved hardness and toughness. At a pressure of 150MPa, the wear resistance of the sample was significantly enhanced compared to that of the metal mold casting, with a reduction in wear volume of nearly 40.0%.

3.3 Effect of Pressure on Material Properties

The effect of pressure on the material properties of ZG14CrMnSiNi steel was further analyzed. It was found that pressure can refine the grain size of the steel, increase the density of dislocations, and promote the formation of fine precipitates. These changes in the microstructure lead to improved mechanical properties such as hardness, toughness, and wear resistance. The relationship between pressure and material properties was quantified, providing a theoretical basis for the optimization of the liquid forging process.

4. Design and Optimization of Liquid Forging Process for Bucket Teeth

The design and optimization of the liquid forging process are crucial for achieving high-quality bucket teeth. In this study, a comprehensive liquid forging process scheme for bucket teeth was designed and optimized.

4.1 Process Design Considerations

The design of the liquid forging process for bucket teeth should consider factors such as the shape and size of the bucket teeth, the material properties, and the production requirements. The process should ensure that the molten metal fills the die cavity completely and evenly, and that the pressure is applied uniformly during solidification. Additionally, the process should be designed to minimize defects such as porosity, shrinkage cavities, and cracks.

4.2 Optimization of Process Parameters

The process parameters of liquid forging, such as the pouring temperature, the pressure, and the holding time, were optimized through experimental studies and numerical simulations. The results showed that the optimal pouring temperature for the ZG14CrMnSiNi steel was 1560°C, the optimal pressure was 150MPa, and the optimal holding time was 70.0s. These optimized parameters ensured the production of bucket teeth with excellent mechanical properties and a defect-free microstructure.

4.3 Numerical Simulation of the Liquid Forging Process

Numerical simulation was used to study the liquid forging process of bucket teeth. The ProCAST simulation software was employed to simulate the filling, solidification, and defect formation processes. The simulation results were compared with the experimental results, and a good agreement was obtained. The numerical simulation provided a valuable tool for understanding the complex physical phenomena involved in the liquid forging process and for optimizing the process parameters.

5. Design and Manufacturing of Liquid Forging Dies for Bucket Teeth

The design and manufacturing of liquid forging dies are critical for the successful production of bucket teeth. In this study, a special die for liquid forging bucket teeth was designed and manufactured.

5.1 Die Design Requirements

The die design for liquid forging bucket teeth should meet the requirements of the bucket teeth shape, the liquid forging process, and the production efficiency. The die should have a reasonable cavity structure, smooth surface finish, and good heat transfer properties. Additionally, the die should be designed to withstand the high pressure and temperature during the liquid forging process.

5.2 Die Structure and Components

The die for liquid forging bucket teeth consists of an upper die, a lower die, a core, and a punch. The upper die and the lower die form the cavity for the bucket teeth, while the core is used to form the internal shape of the bucket teeth. The punch is used to apply pressure to the molten metal during solidification. The die structure was designed to ensure the smooth flow of the molten metal and the uniform application of pressure.

5.3 Die Manufacturing and Quality Control

The die for liquid forging bucket teeth was manufactured using advanced machining techniques such as CNC machining and EDM. The die surface was polished to a high finish to ensure good surface quality. Quality control measures were implemented during the die manufacturing process to ensure that the die met the design requirements. The die was inspected for dimensional accuracy, surface finish, and hardness before and after manufacturing.

6. Experimental Verification and Performance Evaluation of Liquid Forged Bucket Teeth

Experimental verification and performance evaluation were carried out to validate the effectiveness of the liquid forging technology for bucket teeth manufacturing.

6.1 Experimental Setup and Procedures

The experimental setup for liquid forging bucket teeth included a liquid forging machine, a die, a heating system, and a testing system. The liquid forging machine was used to apply pressure to the molten metal during solidification. The die was used to form the shape of the bucket teeth. The heating system was used to heat the molten metal to the required pouring temperature. The testing system was used to measure the mechanical properties and microstructure of the liquid-forged bucket teeth.

6.2 Mechanical Properties Testing

The mechanical properties of the liquid-forged bucket teeth were tested using standard testing methods such as hardness testing, impact testing, and wear testing. The results showed that the liquid-forged bucket teeth had excellent hardness, impact toughness, and wear resistance compared to traditional cast and forged bucket teeth. The hardness of the liquid-forged bucket teeth was increased by nearly 30% compared to that of the metal mold casting, while the impact toughness was improved by more than 50%. The wear resistance of the liquid-forged bucket teeth was significantly enhanced, with a reduction in wear volume of nearly 40.0% compared to that of the metal mold casting.

6.3 Microstructure Analysis

The microstructure of the liquid-forged bucket teeth was analyzed using SEM and EDS. The results showed that the liquid-forged bucket teeth had a dense and uniform microstructure, free from defects such as porosity and shrinkage cavities. The grain size of the liquid-forged bucket teeth was significantly refined compared to that of the metal mold casting, with an average grain size reduction of more than 50%. The refined grain structure contributed to the improved mechanical properties of the liquid-forged bucket teeth.

6.4 Performance Evaluation and Comparison with Traditional Processes

The performance of the liquid-forged bucket teeth was evaluated and compared with that of traditional cast and forged bucket teeth. The results showed that the liquid-forged bucket teeth had superior performance in terms of hardness, impact toughness, wear resistance, and service life. The liquid-forged bucket teeth had a longer service life than traditional cast and forged bucket teeth, with a reduction in replacement frequency of more than 50%. The improved performance of the liquid-forged bucket teeth can lead to increased excavation efficiency, reduced maintenance costs, and improved productivity of the excavator.

7. Industrial Application and Prospect of Liquid Forged Bucket Teeth

The liquid forging technology for bucket teeth has shown great potential for industrial application. In this section, the industrial application cases of liquid-forged bucket teeth are introduced, and the future development prospects of the technology are discussed.

7.1 Industrial Application Cases

Liquid-forged bucket teeth have been successfully applied in various industries such as construction, mining, and infrastructure development. The excellent performance of liquid-forged bucket teeth has been recognized by users, leading to increased market demand. For example, in a mining project, the use of liquid-forged bucket teeth resulted in a significant reduction in bucket teeth replacement frequency, increasing the working efficiency of the excavator and reducing the maintenance costs.

7.2 Market Demand and Potential

The market demand for high-quality bucket teeth is increasing due to the growing need for efficient and reliable excavators. Liquid-forged bucket teeth, with their superior performance and durability, have the potential to capture a significant share of the market. The potential market for liquid-forged bucket teeth includes both domestic and international markets, especially in developing countries where the construction and mining industries are booming.

7.3 Future Development Trends and Prospects

The future development of liquid forging technology for bucket teeth is expected to focus on further improving the process efficiency, reducing production costs, and enhancing the performance of bucket teeth. Research efforts will be directed towards developing new materials, optimizing process parameters, and improving die design and manufacturing. Additionally, the application of advanced manufacturing technologies such as additive manufacturing and intelligent manufacturing is expected to bring new opportunities for the development of liquid forging technology for bucket teeth.

8. Conclusion

In conclusion, the liquid forging technology for bucket teeth offers a promising solution for improving the quality and performance of bucket teeth. The comprehensive research and development work carried out in this study have demonstrated the feasibility and superiority of the liquid forging technology for bucket teeth manufacturing. The optimized liquid forging process, the designed and manufactured liquid forging die, and the excellent performance of the liquid-forged bucket teeth have provided a solid foundation for the industrial application of the technology. With the continuous development and improvement of the technology, it is expected that liquid-forged bucket teeth will play an increasingly important role in the field of excavator bucket teeth manufacturing, contributing to the improvement of excavation efficiency, reduction of maintenance costs, and enhancement of productivity.

8.1 Summary of Key Findings

- The selection of ZG14CrMnSiNi steel as the bucket teeth material and the study of its microstructure and mechanical properties under different pressures have provided a theoretical basis for the optimization of the liquid forging process.

- The design and optimization of the liquid forging process for bucket teeth, including the process design considerations, the optimization of process parameters, and the numerical simulation of the process, have ensured the production of bucket teeth with excellent mechanical properties and a defect-free microstructure.

- The design and manufacturing of the liquid forging die for bucket teeth, including the die design requirements, the die structure and components, and the die manufacturing and quality control, have met the requirements of the bucket teeth shape, the liquid forging process, and the production efficiency.

- The experimental verification and performance evaluation of the liquid-forged bucket teeth have demonstrated the superiority of the liquid forging technology over traditional manufacturing processes in terms of hardness, impact toughness, wear resistance, and service life.

8.2 Implications for the Excavator Industry

The application of liquid forging technology for bucket teeth in the excavator industry can bring significant benefits. It can improve the performance and durability of bucket teeth, reduce maintenance costs, and increase the working efficiency of excavators. This, in turn, can enhance the competitiveness of excavator manufacturers and contribute to the development of the excavator industry.

8.3 Recommendations for Future Research

Future research on liquid forging technology for bucket teeth can focus on the following areas:

- Further investigation of the relationship between process parameters and material properties to achieve more precise control of the liquid forging process.

- Development of new materials with better mechanical properties and cost-effectiveness for bucket teeth manufacturing.

- Application of advanced manufacturing technologies such as additive manufacturing and intelligent manufacturing to improve the efficiency and quality of the liquid forging process.

- Study of the long-term performance and reliability of liquid-forged bucket teeth under actual working conditions to provide more accurate data for industrial application.