1. Introduction

Bucket teeth are crucial components in construction machinery such as excavators and loaders. These components are constantly subjected to extreme conditions including high impact, compression, and bending moments during operation. As a result, they are prone to wear, deformation, and cracking, making it essential for bucket teeth to possess excellent wear resistance and toughness. This article focuses on the forging bucket teeth, specifically exploring the heat treatment processes and their influence on the microstructure and properties of the teeth.

1.1 The Importance of Bucket Teeth

Bucket teeth play a vital role in the efficient operation of construction machinery. They are the first point of contact with the materials being excavated or loaded, such as sand, gravel, and soil. The performance of bucket teeth directly affects the productivity and lifespan of the machinery.

1.2 Challenges in Bucket Teeth Manufacturing

Manufacturing bucket teeth that can withstand the harsh operating conditions is a significant challenge. The choice of material and the appropriate heat treatment process are crucial factors in determining the final properties of the bucket teeth.

2. Materials for Forging Bucket Teeth

Various materials have been used for bucket teeth manufacturing over the years. Early bucket teeth were often made of high manganese steel, but it had limitations in terms of wear resistance under low impact conditions. Currently, low to medium carbon low alloy martensitic steel, such as 30CrMnSi steel, is a popular choice due to its potential to provide a good combination of wear resistance and toughness when paired with the right heat treatment process.

2.1 Comparison of Different Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| High Manganese Steel | Good work hardening under high impact | Poor work hardening under low impact, reduced wear resistance |

| 30CrMnSi Steel | Potential for good wear resistance and toughness with proper heat treatment | Requires careful heat treatment process optimization |

3. Heat Treatment Processes for Forging Bucket Teeth

There are two main heat treatment processes commonly used for forging bucket teeth: reheating and quenching-tempering after forging, and direct quenching using forging residual heat followed by tempering. The latter process is more energy-efficient and is widely used.

3.1 Reheating and Quenching – Tempering Process

This process involves cooling the forged bucket teeth after shaping and then reheating them for quenching and tempering. The quenching step rapidly cools the steel to form a martensitic structure, which provides high hardness. The tempering step then reduces the internal stresses and improves the toughness of the material.

3.2 Direct Quenching Using Forging Residual Heat

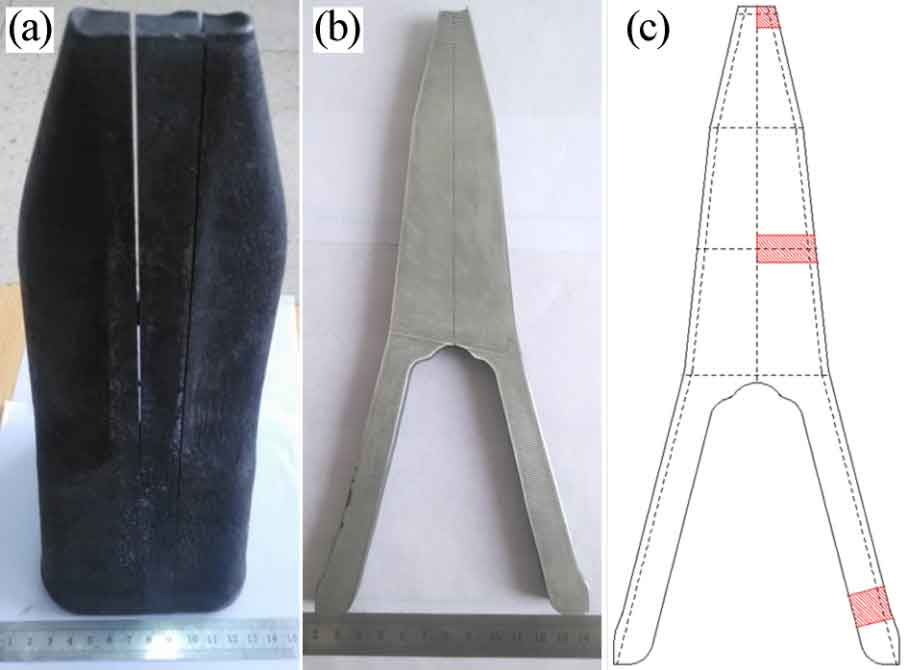

In this process, the bucket teeth are quenched directly using the heat retained from the forging process. This not only saves energy but also can have a significant impact on the microstructure and properties of the bucket teeth. One example of this process is the segmented quenching used in some production lines, where the tooth tip is first quenched in water for a certain period, and then the entire bucket tooth is quenched.

4. Microstructure and Properties of Forging Bucket Teeth

The microstructure and properties of forging bucket teeth are closely related to the heat treatment process used. Different heat treatment conditions can result in variations in hardness, toughness, and the microstructure of the bucket teeth.

4.1 Microstructure Analysis

The microstructure of bucket teeth can vary depending on the heat treatment process. For example, in 30CrMnSi steel bucket teeth, the original microstructure of the hot-rolled and normalized bar stock is typically a combination of white ferrite and black sorbite. After forging and heat treatment, the microstructure may consist of different forms of martensite.

| Heat Treatment Condition | Microstructure |

|---|---|

| As-rolled and normalized | Ferrite + Sorbite |

| After forging and segmented quenching | Plate martensite (with varying sizes in different parts) |

4.2 Hardness Distribution

The hardness of bucket teeth also shows a certain distribution pattern. In general, the surface hardness of the bucket teeth produced by forging residual heat quenching is slightly lower than the subsurface hardness by about 2 – 3 HRC. The hardness of the tooth tip is usually higher than that of the tooth root by 5 – 10 HRC. This is due to the different cooling rates and heat treatment methods applied to different parts of the bucket teeth.

4.3 Impact Toughness

Impact toughness is an important property for bucket teeth as they need to withstand sudden impacts during operation. The impact toughness of 30CrMnSi steel bucket teeth varies with the quenching temperature. When the quenching temperature is 870 °C, the impact toughness is the highest, reaching 74 J. At temperatures below 870 °C, the impact toughness may decrease due to inhomogeneous austenitization or the presence of more ferrite. At temperatures above 870 °C, the austenite grains become coarse during heating, resulting in coarse martensite after quenching and a decrease in impact toughness.

5. Optimization of Heat Treatment Processes

To improve the performance of forging bucket teeth, it is necessary to optimize the heat treatment process. This includes determining the appropriate quenching temperature and method, as well as considering the overall heat treatment cycle.

5.1 Quenching Temperature Optimization

Based on the research, for 30CrMnSi steel, a quenching temperature of 870 °C is found to be optimal for achieving a good combination of hardness and toughness. At this temperature, the microstructure consists of relatively fine martensite, which provides both high strength and good toughness.

5.2 Quenching Method Selection

Rather than using a segmented quenching method where the tooth tip and root are quenched separately, it is suggested to use a whole quenching process where the tooth tip and root enter the water simultaneously. This can ensure that the entire bucket tooth obtains a more uniform martensitic structure, thereby improving the overall hardness and toughness of the bucket tooth.

6. Conclusion

Forging bucket teeth require careful consideration of material selection and heat treatment processes to achieve the desired combination of wear resistance and toughness. The 30CrMnSi steel, when treated with an appropriate heat treatment process such as direct quenching using forging residual heat followed by tempering at an optimal temperature and with a suitable quenching method, can produce bucket teeth with excellent properties. Future research may focus on further optimizing the heat treatment process and exploring new materials and techniques to meet the ever-increasing demands of the construction industry for more durable and efficient bucket teeth.

[Insert relevant images here to illustrate the microstructure, hardness distribution, and heat treatment processes. For example, images of the different microstructures under a microscope, graphs showing the hardness distribution along the bucket tooth, and diagrams of the heat treatment process steps.]

In conclusion, the study of forging bucket teeth’s heat treatment processes and their impact on microstructure and properties is an ongoing area of research with significant practical implications for the construction machinery industry. By understanding and optimizing these factors, manufacturers can produce bucket teeth that offer better performance and longer service life, ultimately contributing to the efficiency and productivity of construction operations.