1. Introduction

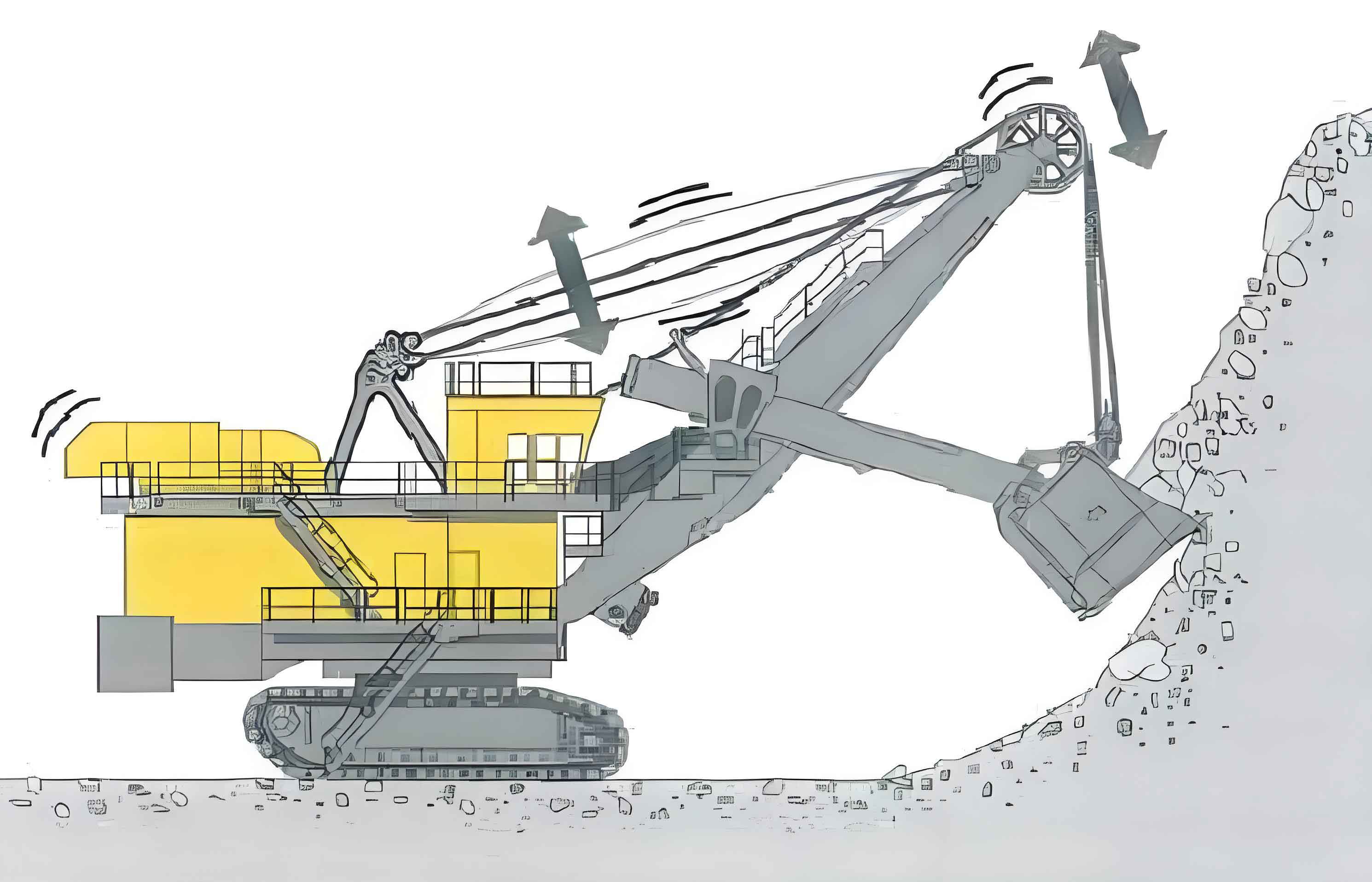

In open-pit mining operations, electric shovels play a crucial role. The bucket teeth of electric shovels are an important part that directly contacts the ore during the shovel loading process. The wear and detachment of bucket teeth can have a significant impact on the efficiency and safety of mining operations. This article will focus on the analysis of bucket teeth in open-pit mine electric shovels, including their working environment, potential hazards, and research on related technologies such as monitoring and alarming systems.

1.1 Working Environment of Electric Shovels in Open-pit Mines

Open-pit mines have complex working environments. The terrain is often uneven, and the weather conditions can be harsh. Electric shovels have to operate in various weather conditions, including extreme heat, cold, rain, and snow. The ore in open-pit mines also varies in hardness and size, which puts different degrees of stress on the bucket teeth during the shovel loading process.

1.2 Importance of Bucket Teeth in Electric Shovels

Bucket teeth are the key components for electric shovels to dig and load ore. They need to have sufficient strength and wear resistance to withstand the impact and abrasion of the ore. The performance of bucket teeth directly affects the productivity and operating costs of electric shovels. If the bucket teeth are worn or detached, it will not only reduce the efficiency of shovel loading but also may cause damage to other equipment, such as crushers.

2. Hazards Associated with Bucket Teeth

2.1 Wear and Tear of Bucket Teeth

The wear and tear of bucket teeth are mainly caused by the abrasion of the ore during the shovel loading process. The hardness and size of the ore, as well as the operating frequency of the electric shovel, all affect the wear rate of the bucket teeth. As shown in Table 1, different ores have different hardness levels, which result in different degrees of wear on the bucket teeth.

| Ore Type | Hardness Level | Wear Rate of Bucket Teeth |

|---|---|---|

| Hematite | High | High |

| Limestone | Medium | Medium |

| Coal | Low | Low |

2.2 Detachment of Bucket Teeth

The detachment of bucket teeth can occur due to various reasons. One of the main reasons is the loosening of the pins that fix the bucket teeth to the bucket. In addition, the fatigue fracture of the bucket teeth themselves can also lead to detachment. The detachment of bucket teeth can cause serious consequences, such as equipment damage and production delays. As shown in Table 2, the detachment of bucket teeth can cause different types of damage to different equipment.

| Equipment | Damage Caused by Bucket Teeth Detachment |

|---|---|

| Crusher | Damage to crusher gears and motors |

| Conveyor Belt | Damage to conveyor belt rollers |

| Electric Shovel | Reduced efficiency of shovel loading, increased operating costs |

3. Analysis of Bucket Teeth Using Numerical Simulation

3.1 Introduction to Numerical Simulation Software

ANSYS Workbench is a widely used numerical simulation software in the field of engineering. It can be used to analyze the mechanical properties of structures, including stress, strain, and deformation. In this study, ANSYS Workbench was used to analyze the bucket teeth of electric shovels.

3.2 Modeling and Simulation of Bucket Teeth

The bucket teeth of a certain type of electric shovel were modeled in ANSYS Workbench. The geometric dimensions and material properties of the bucket teeth were defined according to the actual situation. Then, a static analysis was carried out to simulate the stress and strain distribution of the bucket teeth under different working conditions. the stress distribution of the bucket teeth under a certain working condition is obtained through simulation.

3.3 Results and Analysis of Simulation

The simulation results showed that the stress concentration areas of the bucket teeth were mainly located at the connection between the inner arc and the transverse file of the bucket teeth and the first fixed bolt hole. These areas are more likely to form fatigue cracks and lead to the detachment of the bucket teeth. In addition, the simulation also found that the loosening of the fixing pins can also cause the detachment of the bucket teeth.

4. Research on Bucket Teeth Detachment Alarm Device

4.1 Design Principles of the Alarm Device

The design of the bucket teeth detachment alarm device should follow the principles of reliability, simplicity, and cost-effectiveness. The device should be able to accurately detect the detachment of bucket teeth and send an alarm signal in a timely manner. At the same time, the device should be easy to install and maintain, and have a reasonable cost.

4.2 Components and Working Principle of the Alarm Device

The bucket teeth detachment alarm device mainly consists of a sensor module, a wireless transceiver module, and an alarm module. The sensor module is installed on the bucket teeth and is used to detect the detachment of the bucket teeth. The wireless transceiver module is used to transmit the detection signal to the alarm module. The alarm module is installed in the cab of the electric shovel and is used to receive the signal and send an alarm. the working principle of the alarm device is illustrated.

4.3 Selection of Key Components

4.3.1 Sensor Module

The sensor module should have high sensitivity and reliability. In this study, a magnetic sensor was selected. The magnetic sensor can detect the change in the magnetic field caused by the detachment of the bucket teeth.

4.3.2 Wireless Transceiver Module

The wireless transceiver module should have a stable transmission performance and a suitable transmission distance. In this study, a 2.4GHz wireless transceiver module was selected. The 2.4GHz wireless transceiver module has a wide application range and good transmission performance.

4.3.2 Alarm Module

The alarm module should have a loud alarm sound and a visible alarm indication. In this study, a combination of a buzzer and an LED was selected as the alarm module.

5. Installation and Verification of the Alarm Device

5.1 Installation Process of the Alarm Device

The installation of the alarm device includes the installation of the sensor module on the bucket teeth, the installation of the wireless transceiver module on the electric shovel, and the installation of the alarm module in the cab. The installation process should follow the installation instructions carefully to ensure the correct installation of the device.

5.2 Verification of the Alarm Device

After the installation of the alarm device, a verification test was carried out. The bucket teeth were artificially detached to test whether the alarm device could accurately detect the detachment and send an alarm signal. The test results showed that the alarm device had a high detection accuracy and a reliable alarm function.

6. Conclusion

In this article, the bucket teeth of open-pit mine electric shovels were analyzed from multiple aspects. The hazards associated with bucket teeth, such as wear and tear and detachment, were studied. Numerical simulation was used to analyze the stress and strain distribution of the bucket teeth, and the key areas prone to detachment were identified. Based on this, a bucket teeth detachment alarm device was designed and developed. The installation and verification of the alarm device were carried out, and the effectiveness of the device was verified. This research has important practical significance for improving the safety and efficiency of open-pit mine electric shovel operations. Future research can focus on further optimizing the design of the alarm device and exploring more advanced monitoring and maintenance technologies for bucket teeth.