1. Introduction

Investment casting is a precision casting method widely used in the manufacturing of various components, especially those with complex geometries and high precision requirements. In this article, we focus on the investment casting process of a fixed disk used in an automotive air – conditioning compressor. The fixed disk is a crucial part, and its quality directly affects the performance and reliability of the compressor. By using advanced simulation software and optimization methods, we aim to improve the casting quality and reduce defects.

1.1 Background of the Fixed Disk

The fixed disk is an important component in an automotive air – conditioning compressor. It is made of JDMB2K4140 alloy steel, which has specific chemical compositions as shown in Table 1.

| Element | Si | Mn | Cr | Mo | P | S | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| Composition Range | 0.17 – 0.37 | 0.50 – 0.80 | 0.90 – 1.20 | 0.15 – 0.25 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.30 |

The maximum outer dimensions of the fixed disk are 126mm×75mm×72mm, and it has a uniform wall thickness and a relatively complex structure.

1.2 Importance of Process Optimization

In the investment casting process, various factors can affect the final quality of the casting. Defects such as shrinkage cavities and cracks can occur during the filling, solidification, and cooling processes. Therefore, it is essential to optimize the casting process to ensure high – quality production.

2. Investment Casting Process Design for the Fixed Disk

2.1 Gating System Design

- Pouring Channel Selection: Considering the irregular structure of the fixed disk casting, with a through – hole of 15mm in diameter on the side and an average wall thickness of 7mm, a straight runner – cross runner – ingate system is adopted to ensure a relatively stable filling process and sequential solidification of the casting, reducing the occurrence of shrinkage porosity.

- Pouring Model Establishment: Based on the three – dimensional model of the fixed disk, a three – dimensional model of the pouring system is established. The grid is divided with a grid value of 5mm, resulting in 56352 total grid units and 435310 total nodes.

2.2 Simulation Parameter Settings

In the ProCAST software, accurate simulation parameter settings are crucial for obtaining precise results. The following parameters are set:

- Environmental Temperature: The pouring environment temperature is set to 800℃, and the shell temperature remains unchanged.

- Shell Thickness: The shell thickness is approximately 6mm, consisting of 6 layers of quartz sand refractory material and silica sol combination.

- Material and Pouring Temperature: The material is 42CrMo4 steel, and the pouring temperature is set to 1580℃, considering the relevant alloy liquidus and solidus temperatures (1494℃ and 1425℃ respectively).

- Gravity and Heat Transfer Coefficients: The gravity acceleration is set to 9.8m/s², the heat transfer coefficient is set to 500W/(m²·K), and the heat exchange coefficient between the casting and air is set to 1000W/(m²·K).

3. Initial Process Numerical Simulation Results and Analysis

3.1 Pouring Speed Determination

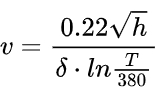

The pouring speed is calculated using the Calkin formula:

After calculation, the pouring speed is 266.105mm/s. Considering the influence of parameter calculation, a pouring speed of 300mm/s is used for simulation.

3.2 Main Process Parameters

- Initial Process Parameters: The initial process parameters include a shell thickness of approximately 6mm, a shell preheating temperature of 1000℃, a pouring temperature of 1580℃, a pouring speed of 300mm/s, and a natural cooling method for the casting. The pouring direction is set as the negative x – direction.

- Filling and Solidification States: The filling process of the initial process scheme is relatively smooth, and the metal liquid does not cause intense impact on the inner wall of the shell. The solidification process of the casting shows that the solidification starts from the workpiece towards the straight runner, which is beneficial for the solidification and quality of the casting.

3.3 Analysis of Defects

The initial process shrinkage cavity distribution map shows that there are relatively serious shrinkage porosity and shrinkage cavities in the arc surface part of the part, as well as in the main runner and the bent part of the part. These defects can have a negative impact on the quality of the casting and may even lead to product scrapping.

4. Optimization of Casting Process Parameters

4.1 Selection of Optimization Parameters

The casting process parameters that affect the forming quality of the casting include the pouring temperature of the metal liquid, the preheating temperature of the shell, the pouring speed, the deoxidation situation, and the cooling speed of the casting. In this study, the former three are mainly analyzed.

4.2 Orthogonal Experiment Design

An orthogonal experiment is designed to optimize the process parameters. The orthogonal experiment table is shown in Table 2.

| Level | Factor A (Pouring Temperature/°C) | Factor B (Pouring Speed/(mm·s)) | Factor C (Shell Preheating Temperature/°C) |

|---|---|---|---|

| 1 | 1550 | 200 | 900 |

| 2 | 1560 | 300 | 1000 |

| 3 | 1580 | 400 | 1100 |

4.3 Results and Analysis of Orthogonal Experiments

Nine groups of process parameter experiment schemes are obtained according to the orthogonal experiment method. The filling time and shrinkage porosity values of each group are calculated and analyzed. The results show that the shrinkage porosity rate of experiment L5 is the minimum (1.7984%), and the shrinkage porosity rate of experiment L2 is the maximum (1.9368%). Based on the principle of the minimum shrinkage porosity rate being the best, the optimal process parameter group A2B2C3 is obtained, and the corresponding process parameters are shown in Table 4.

| Process Parameter | Shell Thickness /mm | Shell Preheating Temperature/°C | Pouring Temperature/°C | Pouring Speed /(mm – s – ) | Filling Time/s | Solidification Time/s | Shrinkage Porosity Rate (%) |

|---|---|---|---|---|---|---|---|

| Value | 6 | 1100 | 1560 | 300 | 3.74 | 368.67 | 1.80 |

5. Comparison of Optimal and Initial Processes

5.1 Filling State Comparison

The filling state of the optimal process is compared with that of the initial process. The optimal process shows a more stable filling process, ensuring better quality of the casting.

5.2 Solidification State Comparison

In the solidification process, the optimal process also has advantages. The solidification sequence and time are more reasonable, reducing the occurrence of defects.

5.3 Shrinkage Porosity Distribution Comparison

The shrinkage porosity distribution of the optimal process is more uniform and less severe than that of the initial process, indicating better quality control.

6. Conclusion

- Through the optimization of the investment casting process of the fixed disk using ProCAST software and orthogonal experiment method, the optimal process parameters are obtained: a shell thickness of 6mm, a shell preheating temperature of 1100℃, a pouring temperature of 1560℃, and a pouring speed of 300mm/s.

- These optimal process parameters can effectively reduce the occurrence of defects in the casting process and improve the quality of the fixed disk casting, providing a reference for the production of similar products.

In summary, the research on the investment casting process of the fixed disk has important practical significance for improving the manufacturing quality and efficiency of automotive air – conditioning compressor components.