1. Introduction

Casting defect, especially shrinkage defect, is a common issue in casting production. The unreasonable design of casting structure is one of the main reasons. This article analyzes several types of casting defects caused by structural problems and proposes corresponding solutions.

2. Defects Caused by Inadequate Feeding

2.1 Case Introduction

- Product: Pump body casting.

- Defect Location: Shrinkage occurs at the roots of the flanges on both sides of the casting and the inner hole of the casting.

- Cause Analysis: The inner hole diameter of the casting is small, the heat dissipation condition is poor, and the wall thickness is thin. The inner gate positions of the two flanges of the casting cool first due to the low temperature of the molten steel during cooling, resulting in the inability to feed the interior of the casting and causing defects.

2.2 Solution

- Process Improvement: Change the direction of molten steel pouring. Make the riser at the flange of the casting at a relatively high temperature and reduce the cooling rate of the riser, so as to effectively feed the casting.

- Effect: After batch verification, the casting defects are completely eliminated.

3. Defects Caused by Small Local Distance and Overheating

3.1 Case Introduction

- Product: Pump body casting.

- Defect Location: Shrinkage occurs at the convex platform with a wall thickness of 6mm. The distance between the outer diameter of the convex platform arc and the outer circle of the connected casting is 3mm, and the diameter of the convex platform is 30mm.

- Cause Analysis: Although the solidification simulation calculation shows that there will be no shrinkage in this part, in actual production, a large thermal node is formed between the convex platform and the cavity, resulting in local overheating and slower cooling than the riser, so that the riser cannot play a feeding role and defects occur.

3.2 Solution

- Structure Improvement: Lengthen the flange and convex platform of the casting by 10mm. By changing the casting structure, the casting thermal node is reduced.

- Effect: After solidification simulation and batch verification, the casting shrinkage is completely eliminated.

4. Defects Caused by Poor Feeding Channel

4.1 Case One

- Product: Cut-off valve body after machining.

- Defect Location: 20% – 30% shrinkage defects occur at the hot node part shown in the product sectional view. The wall thickness of the feeding channel is only 3mm, and the internal heat dissipation condition of the casting is very poor.

- Cause Analysis: The main reason is the unsmooth feeding channel.

4.2 Solution

- Structure Improvement: Increase the wall thickness of the casting.

- Effect: The shrinkage defect is eliminated.

4.3 Case Two

- Product: Thin-walled casting.

- Defect Location: Shrinkage occurs at the intersection of the two walls of the casting (hot node part), that is, at point A.

- Cause Analysis: For thin-walled castings, if there is a hot node, it must be fed, otherwise casting defects will occur. The A part of the casting cannot eliminate the shrinkage defect by methods such as adding risers and forced cooling, and only by changing the casting structure to increase the wall thickness.

4.4 Solution

- Structure Improvement: Increase the wall thickness at point A from 3mm to 6mm, and the bottom wall thickness from 4mm to 5mm. The increased wall thickness can be removed by machining because the inner cavity of the casting is a machined surface.

- Effect: The feeding channel is made smooth to avoid casting shrinkage defects.

5. Defects Caused by Thick-Walled Castings in Inner Cavity

5.1 Case Introduction

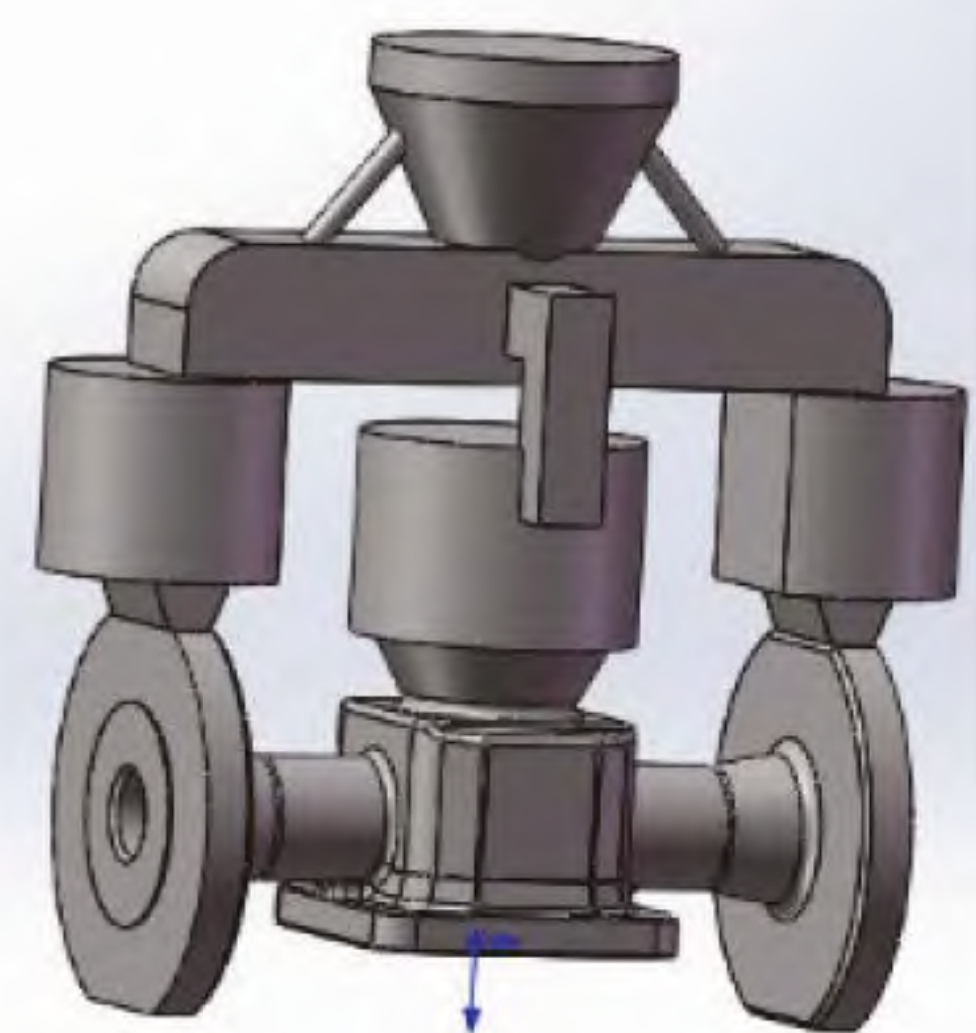

- Product: Large inner cavity thick-walled pump body.

- Defect Location: Shrinkage and porosity defects occur in the thick-walled part inside the casting, and the shrinkage is severe in the thick-walled part inside the casting.

- Cause Analysis: The difference in wall thickness between the inside and outside of the casting is large, more than 30mm. After the shell mold is made, the heat dissipation condition inside the casting is even worse. Although a riser is added outside the casting, due to the large difference in wall thickness, the feeding channel is not smooth, and the shrinkage part of the casting cannot be fed.

5.2 Solution

- Structure Improvement: Plug the middle hole of the casting and add a pouring riser.

- Effect: The thick-walled part inside the casting is fully fed, and the casting defect is eliminated.

6. Defects Caused by Isolated Thermal Nodes

6.1 Case Introduction

- Product: A typical isolated thermal node casting.

- Defect Location: Shrinkage occurs at the isolated thermal node A, and shrinkage also occurs at B after machining.

- Cause Analysis: This casting cannot solve the shrinkage defect by the methods such as adding process ribs, increasing wall thickness, and adding risers described above.

6.2 Solution

- Process Improvement: Before pouring, the C part of the shell mold is locally chilled to make the A position of the casting solidify simultaneously.

- Effect: The casting defect is eliminated.

7. Conclusion

The unreasonable design of casting structure seriously affects the casting cost and yield. The best way to solve the shrinkage defect caused by the casting structure is to communicate with the customer to change the casting structure. If the casting structure cannot be changed, it can only be solved by optimizing the casting process. Product designers should fully consider casting factors during design to ensure the uniformity of casting wall thickness, reduce the number of isolated thermal nodes, and ensure the smoothness of the product feeding channel, thereby reducing casting defects. A reasonably designed casting structure will reduce the casting difficulty and cost and ensure on-time delivery.