I. Introduction

Lost foam casting has developed rapidly due to its advantages. However, casting defects such as sand burning, porosity, and sand washing may occur. This article analyzes the causes of these defects and proposes improvement measures.

II. Analysis and Solution of Casting Defects

A. Sand Burning Defect of Flywheel Housing

- Defect Appearance and Product Information

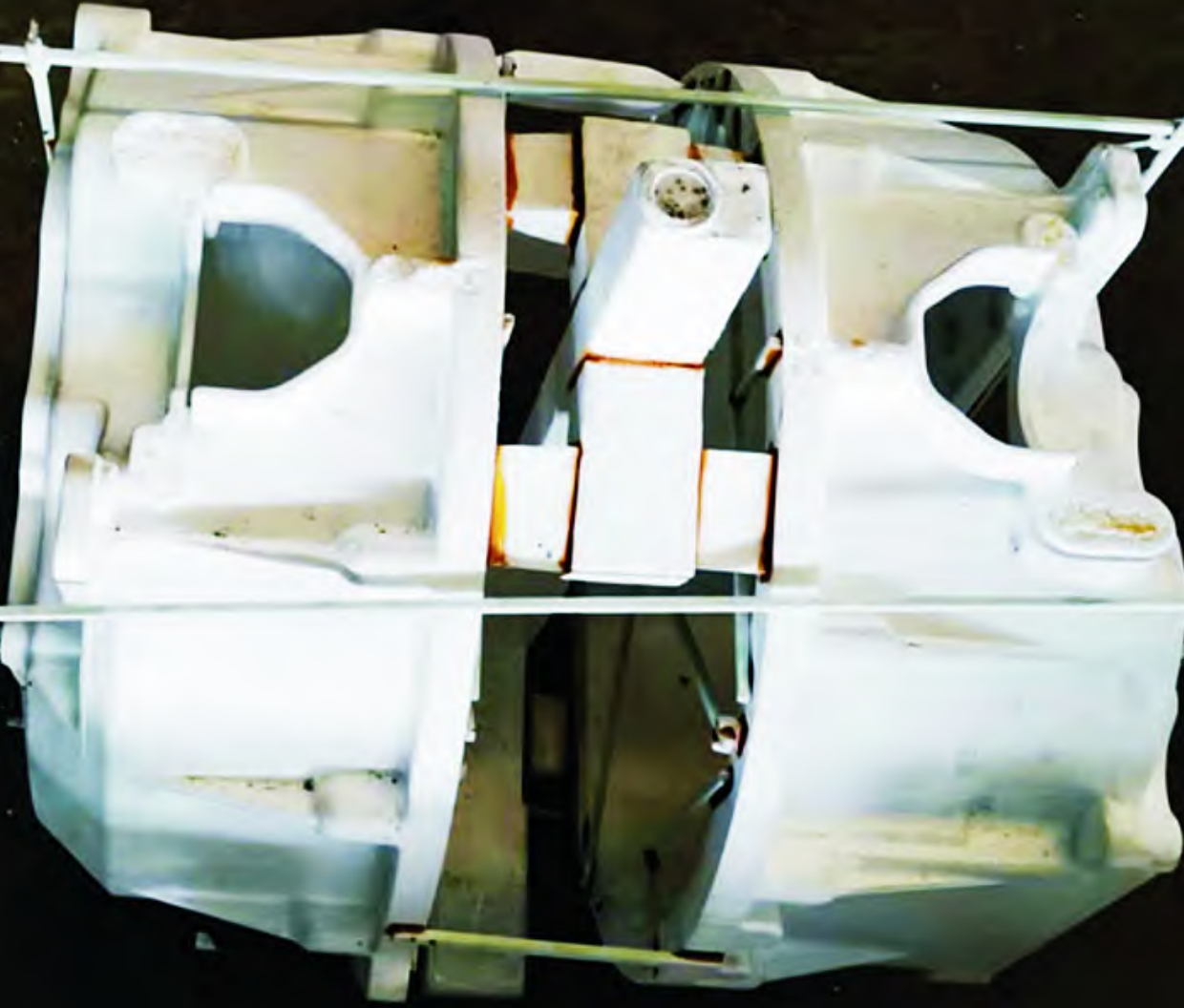

- The sand burning defect of the 9661 flywheel housing is manifested as a mechanical mixture of sand grains and metal adhering to the surface of the shell. The surface shows a metallic luster after cleaning. The product has a mass of about 22 kg, a contour size of 440 mm×440 mm×220 mm, and a wall thickness of 5 mm. The existing process has an inner runner size of 50 mm (length) × 30 mm (height) × 6 mm (width), a molten iron tapping temperature of 1460 – 1470 °C, a pouring temperature of 1430 – 1440 °C, and a vacuum degree of -0.025 MPa. The main defect is sand inclusions at the top of the inner cavity of the flywheel housing, with a scrap rate of 20%.

- Cause Analysis

- The sand burning defect is mainly due to the inability to fill enough molding sand at the top of the flywheel housing or the inability to compact the existing molding sand. In addition, the small gap between the two flywheel housings leads to weak molding sand strength.

- Control Measures and Production Verification

- Adjust the placement of the white pattern to make the motor hole of the flywheel housing face upward to facilitate the filling of molding sand and ensure sufficient molding sand at the top of the flywheel housing.

- Increase the distance between the two flywheel housings from 80 mm to 120 mm to ensure the compactness of the molding sand.

- After the implementation of these measures, the sand burning defect was completely eliminated in the production verification.

B. Porosity Defect of Flywheel Housing

- Defect Appearance and Product Information

- The porosity defect of the SAIC Maxus flywheel housing is manifested as smooth holes of different sizes on the surface after machining, and the hole walls have an oxidized color. The pores are mainly concentrated at the top of the product. The molten iron tapping temperature is 1460 – 1470 °C, the pouring temperature is 1430 – 1440 °C, the vacuum degree is -0.025 MPa, and the scrap rate is 30%.

- Cause Analysis

- The main influencing factors include low pouring temperature, thick local coating thickness, low vacuum degree, and unreasonable process design, which lead to the inability of gas to be discharged in time and the formation of pores.

- Control Measures and Production Verification

- Increase the pouring temperature from 1430 – 1440 °C to 1450 – 1460 °C.

- Reduce the coating thickness from 2.0 mm to 0.5 mm.

- Increase the vacuum degree from -0.025 MPa to -0.045 MPa.

- Add an exhaust sheet with a size of 50 mm (length) × 30 mm (height) × 5 mm (width) at the motor hole.

- Through production verification, adding an exhaust sheet is the best solution, and the porosity defect is completely eliminated.

C. Sand Washing Defect of Connecting Rod Bracket

- Defect Appearance and Product Information

- The sand washing defect of the connecting rod bracket is manifested as a tumor-like mixture of sand grains and metal at the bottom of the cavity and the cavity part where the molten iron flows in at the inner gate. The product has a mass of about 50 kg, a contour size of 572 mm×380 mm×348 mm, and a bottom plate thickness of 12 mm. The existing process uses three inner gates on the side to introduce molten iron, and the inner gate size is 60 mm×30 mm×6 mm. The molten iron tapping temperature is 1460 – 1470 °C, the pouring temperature is 1430 – 1440 °C, the vacuum degree is -0.03 MPa, and the scrap rate is 20%.

- Cause Analysis

- The main influencing factors are the low coating strength of the inner gate and the high pressure of the inner gate, which lead to the cracking of the coating and sand washing.

- Control Measures and Production Verification

- Increase the coating thickness of the inner gate by one dip coating process, and the coating thickness is 2.2 mm.

- Add an inner gate at the bottom.

- Through production verification, adding an inner gate at the bottom is the best solution, and the sand washing defect is completely eliminated. The final process uses four inner gates on the side for liquid inlet, and the ratio of the areas of the sprue, runner, and inner gate is 1960 mm²: 2000 mm²: 1920 mm², which basically meets the 1:1:1 condition.

III. Conclusion

In the process of developing new products, casting defects should be avoided through process design. In the process of process verification, the number of products should be gradually increased from small batches to large batches to avoid losses. The process verification should be carried out step by step from five aspects: understanding the current situation, analyzing the causes, formulating plans, implementing countermeasures, and confirming the effects to finally solve the problems completely.