Abstract: This article focuses on the defect analysis and solution strategies for high toughness ductile iron cylinder heads, aiming to enhance the internal structure compactness and product quality of ductile iron castings. Through detailed research on solidification characteristics and effective casting processes, the formation of casting defects such as shrinkage porosity and gas porosity is controlled.

1. Introduction

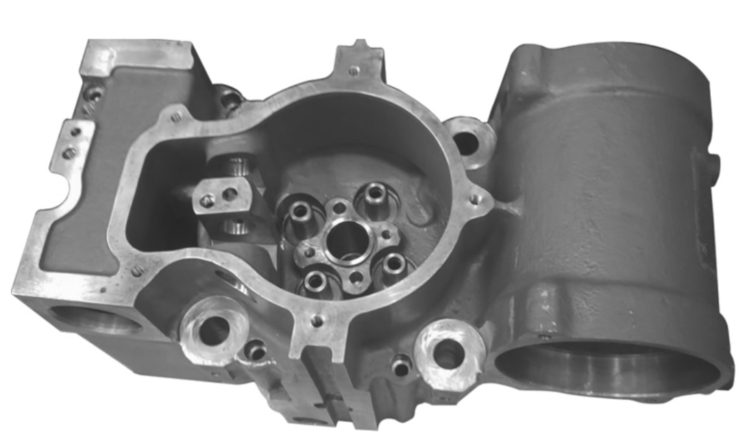

Cylinder heads for high-speed and heavy-duty marine diesel engines are mostly made of high-toughness ductile iron due to their excellent mechanical properties. However, the production of these cylinder heads faces significant challenges, including casting defects such as shrinkage porosity and gas porosity. This article summarizes the defect analysis and solutions for high-toughness ductile iron cylinder heads through practical case studies.

2. Defect Analysis and Solutions

The following table summarizes the main casting defects of high-toughness ductile iron cylinder heads, their causes, and corresponding solutions.

| Defect Type | Cause Analysis | Solution Strategies |

|---|---|---|

| Shrinkage Porosity | – Compact structure with multiple isolated hot spots<br>- Difficulty in controlling cooling and solidification rates<br>- Limited casting measures for feeding | – Placement of 25mm × 60mm round steel chill at the valve guide hole<br>- Pre-placement of 8mm internal chill in the exhaust duct guide hole<br>- Use of chromite sand with high thermal storage coefficient for injector hole cores<br>- Use of chromite sand-coated chill for bolt holes<br>- Placement of external chill at the inlet pipe flange gating edge |

| Gas Porosity | – Complex structure with 27 sand cores<br>- Gas generation during pouring due to hot-box coated sand cores | – Low-temperature baking of injector hole cores at 180°C for 4 hours<br>- Drilling ventilation holes in the coated sand cores before assembly and leading them outside the mold |

3. Detailed Analysis and Solutions

3.1 Shrinkage Porosity

Cause Analysis:

The cylinder head has a compact structure with multiple isolated hot spots, making it difficult to control the cooling and solidification rates of various parts. Additionally, the limited casting measures for feeding result in shrinkage porosity and shrinkage defects at hot spots such as valve guide holes and bolt holes.

Solution Strategies:

- Chill Placement: Chills are strategically placed to accelerate the cooling rate of hot spots, promoting early graphitization expansion and reducing shrinkage defects.

- Material Selection: Chromite sand with high thermal storage coefficient is used to make injector hole cores, enhancing heat transfer and solidification.

3.2 Gas Porosity

Cause Analysis:

The complex structure of the cylinder head requires 27 sand cores, all made of hot-box coated sand. During pouring, the sand cores generate a large amount of gas that cannot be completely expelled from the mold cavity, leading to gas porosity defects.

Solution Strategies:

- Baking Process: The injector hole cores are baked at a low temperature to reduce gas generation.

- Ventilation Holes: Ventilation holes are drilled in the coated sand cores to allow gas to escape, ensuring a smooth pouring process.

4. Implementation and Effect Verification

The proposed solutions were implemented in production, and the following measures were taken to ensure the quality of sand cores and chills:

- Cold Iron Positioning: Chills were positioned within the core boxes and grooves were machined on the chills to increase sand adhesion, preventing displacement or detachment during core making.

- Inspection: The implementation of measures was inspected during the first trial production.

Effect Verification:

- Initial Trial: After the first trial of 20 cylinder heads, the surface quality was good, and no gas porosity defects were observed.

- Random Inspection: A random inspection of one cylinder head through sectioning revealed no shrinkage porosity or shrinkage defects.

- Production Results: With the implementation of the solution, the finished product rate increased to 95% out of 400 produced cylinder heads.

5. Conclusion

For complex castings with high internal quality requirements, such as high-toughness ductile iron cylinder heads, the use of special sands combined with chill processes can accelerate the cooling rate of local hot spots, eliminating shrinkage porosity and effectively addressing defects in these areas. This approach ensures the production of high-quality ductile iron castings with a dense internal structure.

By adopting these strategies, manufacturers can significantly improve the quality and yield of high-toughness ductile iron cylinder heads, meeting the increasing demands of the marine diesel engine industry.