Abstract: The various casting defects encountered during the production of a gantry-style cylinder block on an automated assembly line. Through comprehensive analysis and verification of changes to the gating system, exhaust system, and process parameters, effective solutions to these casting defects are proposed, ensuring the cylinder block meets processing and assembly requirements. Keywords: Gantry cylinder block, casting defects, solution measures.

1. Introduction

The gantry-style cylinder block is characterized by its oil pan mounting plane being positioned below the rotational center of the crankshaft. Its strengths lie in excellent strength and rigidity, enabling it to endure significant mechanical loads. However, it suffers from poor processability and a bulky structure. The 226B cylinder block produced in our factory is a typical example of a gantry-style design. As our factory has expanded, the process route has been adjusted, transitioning from manual core making, handling, and assembly to large-scale, automated, and streamlined production. This transition has introduced a series of casting process and processing assembly issues. Through continuous process optimization and quality improvement, the quality of the castings has seen significant enhancement.

This paper provides a detailed introduction to the causes and mechanisms of casting defects in the gantry-style cylinder block, along with corresponding solution measures. It aims to serve as a reference for other manufacturers.

2. Causes and Solution Measures of Casting Defects

2.1 Cold Shut Defects

The gantry design results in large upper and lower surfaces of the casting, with critical locations such as the water jacket facing downwards, effectively avoiding defects like pores, non-metallic inclusions, and broken cores. However, the large upper plane, with a wall thickness of approximately 5.5mm, is prone to cold shuts, especially in thin-walled areas. Cold shuts occur when molten metal fails to properly fuse at the juncture of metal streams during mold filling, resulting in penetrating or non-penetrating gaps or voids in the casting, with a smooth appearance.

Cause Analysis:

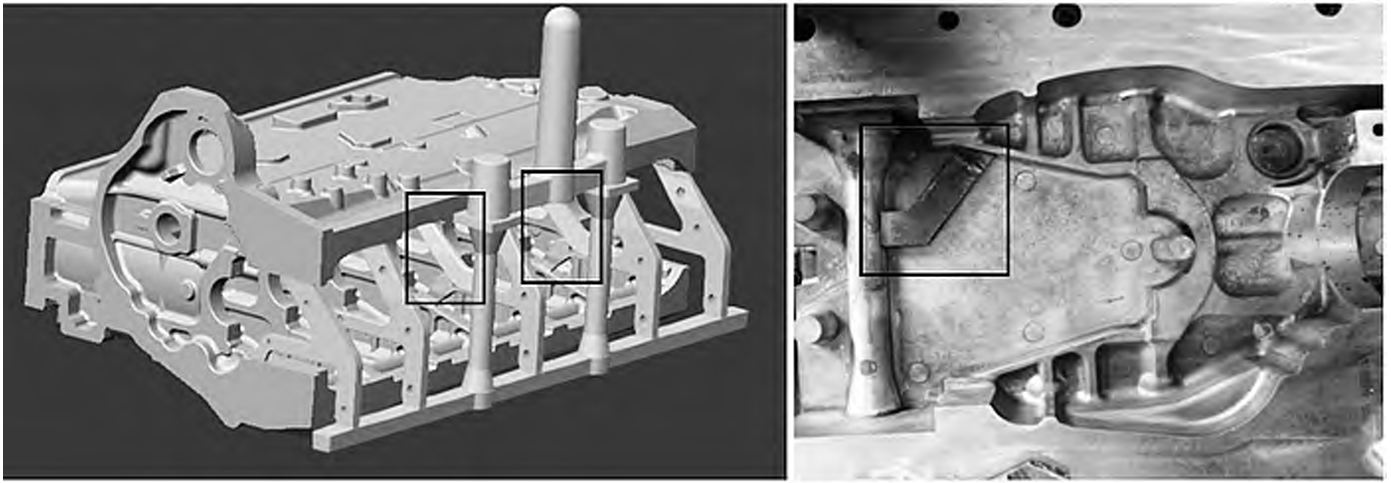

The cylinder block casting weighs 195 kg, with a pouring weight of 238 kg and a pouring time of approximately 21 seconds. The cold shut defects are attributed to an improperly designed gating system. The ingate is too far from the upper plane, causing the gas vents on the upper plane to be dispersed due to the irregular arrangement of bosses, with no ingate at the positions corresponding to the three and five cylinder valve covers, resulting in molten metal converging from the center and two sides towards the middle between the second and third, and fourth and fifth cylinders. The thin wall of the casting leads to rapid heat loss and a quick drop in metal temperature, especially in the area behind the gear chamber, where insufficient molten metal replenishment results in cold shuts.

Solution Measures:

Additional ingates (with a cross-section of 5mm × 25mm) were added within the boxed area, while the design of the ingates at the corresponding positions of other valve covers was changed to 7mm × 20mm, maintaining the total cross-sectional area of the ingates unchanged. This gating system improves the rationality of molten metal filling, enhances metal fluidity, achieves good metal diversion, and reduces the convergence of molten metal from different ingates on the large plane. Production verification has confirmed the effectiveness of the improvements, resolving the cold shut defects and significantly reducing corresponding pore defects.

2.2 Pore Defects

Pores are classified into intrusive pores, evolved pores, and reaction pores based on their formation mechanisms. The pores in the cylinder block are mostly intrusive, primarily due to gas generation from the sand core and molding sand, ultimately forming defects as bubbles in the casting. Based on the causes of pore formation, the following measures are currently implemented:

- Control of Residual Moisture in Sand Cores:

- The storage time of sand cores after emerging from the drying kiln should not be too long. Sand cores with a residual moisture content below 0.6% are allowed for pouring to control gas generation during pouring.

- Increase Pouring Temperature:

- The pouring temperature is appropriately increased within a reasonable range, from the original 1390-1400°C to 1410-1420°C, to improve the fluidity of molten metal on thin-walled planes and slow down the formation of oxide films on the metal surface.

- Strict Control of Molding Sand Moisture:

- The moisture content is controlled below 2.9%. While ensuring strength, the addition of bentonite is reduced to improve the permeability of the molding sand.

- Attention to Sand Core Quality and Assembly Clearance:

- To prevent the堵塞出气通道 caused by fire breakthrough, attention is paid to sand core quality and assembly gaps. Thicker sand cores (such as large cylinder cores) generally have exhaust channels. Incomplete sand core shooting or excessive gaps with other sand cores may allow molten metal to enter the exhaust channels, blocking them and preventing gas from escaping from the sand core.

- Optimization of Risers and Vent Pins Layout:

- The locations of pores are recorded, and the risers and vent pins on the upper side of the casting are rearranged and dimensionally optimized. Additional vent tabs are added at positions corresponding to the cylinder bores on the upper surface of the casting to facilitate the expulsion of gases volatized from the sand cores. Irregular bosses with vent pins are connected to nearby bosses with vent pins or directly.

The pore defects are now effectively controlled, with a reduction from 5.4% to approximately 2%.

2.3 Damage Defects

The gantry-style cylinder block has a higher degree of integration compared to the conventional type, with relatively large upper and lower planes of the horizontally poured cylinder block casting, resulting in an increased number of risers. The larger contact area with equipment and roller conveyors on the casting cleaning line increases the risk of damage.

2.3.1 Damage Caused by Human Operation

- Damage During Removal of Risers:

- Particularly for vent pins set on slender bosses, removal can easily damage the boss. If the damage does not affect the boss processing, it generally requires weld repair; otherwise, the casting is scrapped, causing significant waste. The measure taken is to increase the gap between the boss and the vent pin diameter and provide a tabular structure between them, ensuring that the fracture occurs at the junction, with the tabular structure ensuring sufficient processing allowance for the boss after fracture.

- Damage During Removal of Ingates:

- Previously, the ingate was located at the valve cover position of the cylinder block casting. Molten metal passing through the ingate can cause coarse grain structure at this location, affecting quality and performance. Improper cleaning can also damage the valve cover. Therefore, the position corresponding to the ingate was improved, from the valve cover to the side wall above the valve cover.

2.3.2 Damage Caused by Machinery

During the processes of removing the gating system and vibrating sand removal, bosses corresponding to the lower side in contact with the equipment are prone to bumping and cracking. Such damage requires the boss diameter to be thickened or reinforcing ribs added based on subsequent processing and assembly requirements. Additionally, refining the casting cleaning operation process, establishing detailed operational standards, and conducting targeted training for cleaning operators are greatly beneficial in reducing cleaning damage.

3. Conclusion

The gantry-style cylinder block has a higher degree of integration compared to the conventional type, with relatively large upper and lower planes of horizontally poured castings, which are prone to defects such as cold shuts, misruns, porosity, and shrinkage. In automated casting cleaning lines, the risk of human and machinery-induced damage increases. This paper mainly introduces the cold shut, pore, and damage defects encountered and corresponding improvement measures, hoping to provide a reference for similar casting processes.

Table of Common Casting Defects and Solution Measures

| Casting Defect | Cause Analysis | Solution Measures |

|---|---|---|

| Cold Shut | Improperly designed gating system; far ingate from upper plane; rapid heat loss | Improve gating system design; add additional ingates; optimize metal flow |

| Pore | Gas generation from sand core and molding sand; insufficient ventilation | Control residual moisture in sand cores; increase pouring temperature; improve molding sand permeability; optimize vent system layout |

| Damage | Human operation errors during cleaning; machinery impact during processing | Improve boss design for easier cleaning; move ingate position; provide training for cleaning operators; strengthen boss structures |

By addressing these casting defects through comprehensive analysis and targeted solution measures, the quality of the gantry-style cylinder block can be significantly enhanced, ensuring it meets processing and assembly requirements. This paper aims to provide valuable insights and practical guidance for manufacturers facing similar casting challenges.