Abstract

In order to further enhance the quality of large diesel engine intermediates and fulfill the escalating technical requirements of products, a thorough analysis of the current quality status was conducted, followed by the optimization and design of the casting process for these intermediates. By refining the molding process, melting process, and coordinating with quality control measures during operations, the quality of castings produced through several process optimization experiments was rigorously compared. Ultimately, the quality of the intermediates was significantly improved, and the process improvements were effective, meeting the technical requirements.

1. Introduction

With the advancement of science and technology and the elevation of productivity levels, the quality demands for castings have become increasingly stringent. As the shipbuilding industry in China rapidly progresses, the localized production of marine large diesel engines, which are essential for supporting this industry, must keep pace to fulfill the practical needs of ship construction. The trend towards larger diesel engine models in our company necessitates addressing the increasing casting difficulty of larger intermediates. Consequently, there are more rigorous requirements for the quality of castings and flaw detection in intermediate components. The previous quality standards for castings have gradually become inadequate for current and future developments.

2. Quality Issues of Intermediates

Recently, the quality issues of large diesel engine intermediates produced by our company have been quite severe, primarily manifested in defects that emerge after processing, often requiring repairs. These issues not only cause delays in the submission of diesel engine products but also tarnish the company’s reputation.

After investigation and analysis, the quality issues of intermediates mainly include:

(1) Defects in Bearing Hole Positions

The bearing hole positions of large models (60 and above) show a higher number of defects after rough and finish machining, while smaller models are basically defect-free. Analysis of the company’s unqualified products over the past two years reveals that the most defective intermediate model is the rear main intermediate of Flex60MC-C, accounting for 78.5% of unqualified intermediates. The primary defects occur in the bearing hole positions. Defects are more prevalent as machining progresses internally, with magnetic particle inspection revealing an increasing number of excessive magnetic indications, mainly in the form of approximately 3-5 mm long magnetic traces, followed by porosity, inclusions/slag, and other casting defects.

(2) Shrinkage Defects

Shrinkage porosity and shrinkage cavities are prone to occur at the juncture of the reinforcement plates on both sides of the rear end of the intermediate and below the middle riser at the rear end.

(3) Poor Weld Repair Quality

Areas where castings have undergone weld repairs often leave weld defects. The welded reinforcement plates have significant size deviations, necessitating frequent overlay welding corrections.

(4) Poor Surface Quality

Castings frequently exhibit surface defects such as sand holes, slag inclusions, steel-sand inclusions, porosity, watermarks, shrinkage porosity and shrinkage cavities at the root of risers.

(5) Dimensional Offsets

After rough machining and marking of intermediate blanks, it was found that the dimensions of the reinforcement plates of the castings deviated significantly in one direction.

3. Status of Defects

The causes of casting defects are numerous, with imperfections in casting processes and operational management being the primary factors. Other contributing factors include production constraints and the heightened quality requirements for castings.

4. Causes of Defects

(1) Insufficient Feeding and Poor Riser Design

Shrinkage porosity and shrinkage cavities often occur at the rounded corners near the juncture of the reinforcement plates on both sides of the rear end of the intermediate. This is attributed to poor insulation of the risers or undersized risers with moduli insufficient to meet the actual feeding requirements of the casting.

During riser design, to facilitate easier cleaning of the casting, the riser center is deviated from the hot spot center, and the chill below the riser fails to exert its intended chilling effect, resulting in inadequate feeding.

The feeding capacity of the middle waist-shaped open riser may be insufficient. Its center is located at the machining area of the bearing hole surface, and the area directly below the center of the riser is the most susceptible to defects.

Poor riser quality is also a significant factor. After pouring and solidification of the rear main intermediate, dissecting the used microbead insulation riser showed that its shrinkage was comparable to that of the sand-type riser. This indicates that the quality of the microbead insulation riser is poor, and its actual modulus is much smaller than the standard modulus it should achieve. This directly affects the final solidification and contraction of the casting. Since the riser above the bearing hole is the last to solidify, if the riser’s effect does not meet the design requirements, shrinkage porosity is easily produced at the bottom of the riser.

(2) Pouring Process Issues

The pouring gate has a small flow rate, leading to a prolonged pouring time. Additionally, the pouring temperature is not stable, fluctuating between high and low.

(3) Excessive Machining of Bearing Holes

Generally, the density of the external portions of a casting is better than that of the internal portions. Excessive machining may remove the layer with better density, exposing areas with poorer density. This makes it easier for excessive indications to appear during magnetic particle inspection.

(4) Raised Quality Standards for Castings

As the quality requirements for castings increase, previously acceptable defects have become unacceptable. The flaw detection standards for castings have also been raised accordingly, revealing previously acceptable fine linear defects as unacceptable.

(5) Repeated Defects Due to Multiple Repairs

Due to the high number of initial defects, there are numerous areas requiring weld repairs. In the absence of guaranteed weld repair quality, defects repeatedly appear in the same locations, significantly impacting casting quality and company reputation.

(6) Raw Material Quality

Poor control over scrap steel procurement can lead to impurities such as alloys mixing into the raw materials, which is a cause of oxidative inclusions. High moisture content in raw materials, inadequate redox operations during melting, and excessive gas content in the steel liquid can result in impurities and oxides that cannot be completely removed, ultimately manifesting as oxidative inclusions in the casting.

(7) Casting Difficulty

The larger the casting’s mass, the higher the casting difficulty. The bearing hole area of the intermediate undergoes prolonged high-temperature conditions during steel liquid filling and solidification, leading to complex solidification and crystallization conditions. This area is also where oxides, inclusions/slag, and gases in the steel liquid finally accumulate, making it prone to defects.

(8) Dimensional Offsets

Castings are prone to deformation during heat treatment or weld repairs, causing the positions of reinforcement plates to shift. Additionally, discrepancies between the referencing benchmark for marking and considerations in the casting process contribute to dimensional offsets.

Among all the issues mentioned, the most crucial is the imperfect riser design in the casting process, leading to insufficient feeding, which is the primary cause of magnetic indications in the bearing holes of intermediates.

5. Improvement Measures and Implementation

The quality issues of intermediate castings involve many aspects, including casting processes, field operations, quality control, quality inspection, and production equipment. Corresponding measures are taken to address issues at different stages. Firstly, further improvements are made to deficiencies in the casting process. Secondly, the standardization and discipline in the operation process are enhanced to improve casting quality.

Process improvement is the focus of quality improvement, with molding and melting processes being the primary focus, supplemented by enhanced control over other processes during operation.

5.1 Improvements in Molding Process

5.1.1 First Improvement

(1) Process Plan

Modifications for the first process improvement trial of the diesel engine intermediate casting involved several key adjustments to address the quality issues observed. These modifications included:

- Relocation of Rear Risers: The two rear risers were moved towards the center of the casting to improve the feeding efficiency and reduce the occurrence of shrinkage defects in the critical areas.

- Removal of Chill Below Middle Riser: The chill previously positioned below the middle riser was removed to prevent interference with the feeding process and ensure a more uniform solidification pattern.

- Modification of Middle Riser: The middle riser was also moved towards the center and its height was increased from 800 mm to 850 mm. This adjustment aimed to enhance the feeding capability of the riser, particularly in the areas close to the bearing holes.

- Addition of Chills at Bearing Hole Positions: To improve the solidification quality of the bearing hole regions, 14 blocks of chill measuring 130 mm × 110 mm × 90 mm were added. These chills would accelerate the cooling rate in these areas, reducing the likelihood of defects such as porosity and shrinkage.

- Adjustment of Rough Machining Allowance: The rough machining allowance at the bearing hole positions was adjusted from 25/30 mm to 18/20 mm. This reduction in machining allowance was intended to preserve the denser, higher-quality metal closer to the final bearing hole surface.

- Modification of Pouring Gate Position: The position of the pouring gate was adjusted to be farther away from the middle riser. This change aimed to minimize turbulence during pouring and ensure a smoother flow of molten metal into the casting.

(2) Quality Assessment

After implementing the first process improvement, the castings were subjected to rigorous quality checks. Visual inspections of the casting surfaces revealed no major defects. Ultrasonic and magnetic particle inspections of the bearing holes after rough machining showed no issues. However, as the bearing holes were progressively machined to their final dimensions (ϕ754 mm), an increasing number of fine magnetic particle indications were observed. Specifically, one indication was found after the first cut, three after the second, seven after the third, and over a dozen after the fourth and fifth cuts. This indicated that while the process improvement had reduced the number of defects, it had not fully eliminated them.

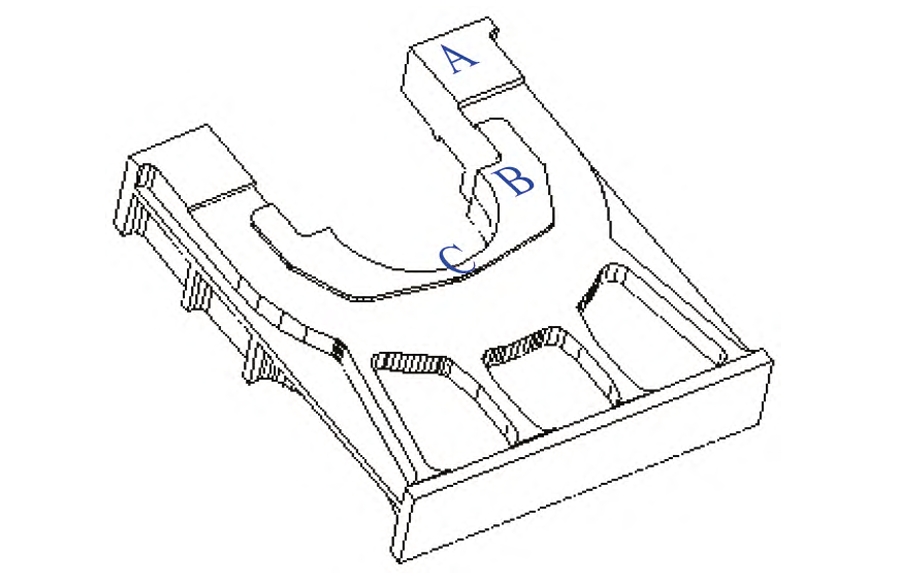

A mechanical properties test was also conducted on samples taken from different regions of the casting. The test results showed that the mechanical properties generally met the technical requirements, with only one sample in the B region falling slightly below the hardness specification of 120 HBW (measured at 113 HBW). The samples from the bearing hole position (C region) met the technical requirements.

Despite the improvements, the first process modification was deemed insufficient due to the persistence of magnetic particle indications in the bearing hole area. Further analysis revealed that the insulation effect of the microbead thermal insulation risers was inadequate, and the feeding capacity of the middle riser was still insufficient. Additionally, the safety margin for the risers at the intersection of the rear side plates was too low, increasing the risk of shrinkage defects.