Abstract:

The factors influencing the conformity accuracy between simulation tests of railroad wagon steel castings primarily encompass discrepancies between physical objects and designed models, test specifics, and simulation methodologies. Employing cause-and-effect analysis, process analysis, physical testing, experimental research, and simulation analysis, this paper proposes enhancements to model accuracy, test specifics, and simulation approaches for steel castings. These improvements were applied and validated on the steel casting bolster of an export vehicle product, resulting in an increased conformity accuracy of static test and simulation data to 90%.

1. Introduction

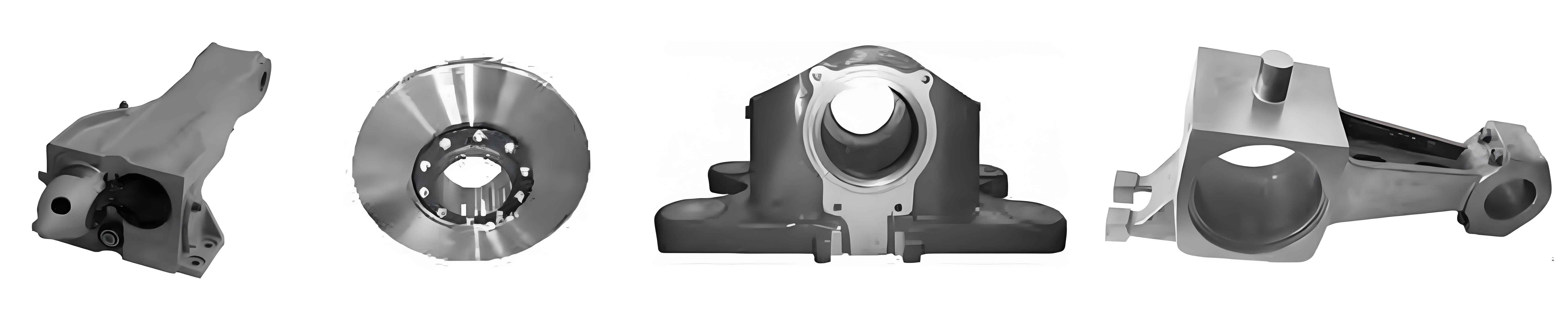

In the components of railroad wagons, steel castings exhibit stable load-bearing capacity, facilitate large-scale production, and offer low manufacturing costs. Consequently, numerous critical load-bearing components, such as bolsters, side frames, couplers, coupler guards, and integral traction beams, utilize steel castings. Simulation and testing serve as vital means to evaluate the reliability of steel castings, and enhancing their conformity accuracy can effectively elevate the design quality of steel castings.

2. Identification of Influencing Factors

The process of identifying influencing factors for simulation and testing conforms to the five aspects of “Man, Machine, Material, Method, and Environment” , analyzing various factors in modeling, testing, and simulation to propose improvement methods.

Table 1: Summary of Influencing Factors

| Aspect | Influencing Factors |

|---|---|

| Man | Standardization of operational procedures |

| Machine | External objective factors related to equipment |

| Material | Discrepancies between physical castings and designed models |

| Method | Ability of simulation methods to replicate testing processes |

| Environment | External objective factors related to environment |

3. Analysis of Influencing Factors

3.1 Discrepancies Between Physical Castings and Designed Models

The manufacturing process of steel castings is intricate, involving design, process planning, mold manufacturing, and production in the workshop, during which the model undergoes evolution.

The simulation model uses the designed 3D model, which reflects nominal design dimensions. The 3D model at the mold manufacturing stage is the closest to the physical model, differing only by material shrinkage ratios. Utilizing this 3D model in simulations can narrow the gap between physical objects and simulation subjects, effectively enhancing the conformity accuracy between simulations and tests.

3.2 Test Specifics

To improve the conformity accuracy between tests and simulations, test data must meet criteria for repeatability, linearity, and symmetry. A common issue in test data is asymmetry, leading to misinterpretation and impacting the conformity accuracy between tests and simulations.

Table 2: Main Sources of Test Data Asymmetry

| Source | Description |

|---|---|

| Measurement Point Layout | Position and direction accuracy of strain gauges, surface quality of test specimens |

| Specimen Placement | Accuracy of relative positional relationships among test equipment, tooling, and specimens |

| Geometric Tolerance of Specimens | Local warping due to surface flatness or parallelism, causing asymmetric test data |

3.3 Simulation Methods

Simulation models must truthfully reflect the relationship among equipment, tooling, and test specimens. Analyzing the load transfer path in tests and correctly setting boundary conditions in models can再现 the role of equipment tooling through appropriate simulation means.

The elastic modulus of steel castings in simulation models is recommended to be 200GPa, with discrete elements preferably choosing 6mm hexahedral elements or 8-12mm ten-node tetrahedral elements.

4. Verification of Conformity Accuracy in the Simulation and Testing of Steel Casting Bolsters

Taking the vertical working condition of a bolster for an export product as an example, this section studies the impact of physical objects, improves test specifics and simulation methods, and verifies conformity accuracy.

4.1 Physical Testing and Impact Research

Utilizing industrial computed tomography (CT) detection technology facilitates internal structural dimension measurements of steel casting products. A CT scanning scheme for critical cross-sections of the bolster was determined.

Table 3: Comparison of Actual and Designed Dimensions

| Position | Actual Measurement | Nominal Dimension (Design) | Difference |

|---|---|---|---|

| Vertical Lower Wall Thickness | Greater | — | — |

| Vertical Upper Wall Thickness | Smaller | — | — |

| Lateral Wall Thickness | Slightly Smaller | — | — |

| Additional Process Ribs | Present | — | — |

| Internal Rib Shape | Obvious Draft Angle, Thicker | — | — |

| Weighing Result | 10kg Heavier | — | — |

Simulation comparisons were conducted between the digital model of the sample and the designed digital model under the vertical condition of the bolster’s center plate. Displacement values differed by 3%, with the digital model of the sample yielding slightly smaller results. Stress differences averaged 8.9% at two key stress points, with CT model stress results being slightly smaller.

4.2 Adjustment of Test Specifics

During static testing of the bolster, strain gauges at the A-locations on both sides of the bolster exhibited asymmetry due to warping of the spring bearing platforms. After alignment testing, it was found that although the product met design standards, adjustments were necessary during testing to improve the symmetry of results.

4.3 Simulation Settings

The static test equipment for the bolster was a 5000kN four-column press test machine, consisting of a base workbench, bottom loading cylinder, and top fixed platen. The simulation model is settings detailed in Table 2.

4.4 Verification Results

Using improved testing and simulation methods, a conformity verification study was conducted on the bolster. With 99 strain measurement points arranged, the displacement conformity between tests and simulations reached 95%. The relative error percentage of stress between simulations and tests followed a normal distribution, with an average relative error of 9.6%, a standard deviation of 2.8%, and a calculated accuracy of 90.4%.

5. Conclusions

Through research on the conformity accuracy between simulations and tests of large steel castings for railroad wagons, it was found that test specimens, test specifics, and simulation methods have the greatest impact on conformity accuracy.

Due to the complexity of the manufacturing process, the dimensional information of physical objects reflects a combination of various process and manufacturing factors, differing from designed models. These statistical regularities can be referenced in design structures. In the evolution of steel casting models, the 3D mold model is closest to the physical model, suggesting its reasonable use in the simulation process for more ideal results.

The rational realization of test devices in simulation models is crucial for improving conformity accuracy, and the impact of operational details in physical tests on data cannot be overlooked. Strict control over test specifics ensures data rationality.

This research method has been validated on bolster products and provides solutions for similar issues with other large steel castings for railroad wagons.