Abstract:

In this comprehensive study, we delve into the causes and influencing factors of casting process defects in products intended for motor train units (MTUs). By employing a multitude of analytical techniques, including macroscopic observation, metallographic examination, mechanical property testing, chemical composition analysis, scanning electron microscopy (SEM) with energy dispersive spectroscopy (EDS), fracture analysis, and trace analysis, we analyze several defective casting products. The results reveal that defects arising during the casting molding process, heat treatment, and repair processes primarily encompass original casting defects, poor microstructure, uneliminated original defects after welding repairs, and defects stemming from inadequate machining. This paper aims to provide insights into the sources of these defects and suggest measures for improvement.

Keywords: casting product; casting process; casting defect; poor welding repair process; casting molding; microstructure

1. Introduction

Casting products play a pivotal role in motor train units, particularly in critical components such as high-speed bogies, couplers, traction systems, and braking systems. These components are typically made from cast steel, cast iron, or cast aluminum to meet the stringent requirements for strength, stiffness, and durability during high-speed operation. However, the manufacturing process of these casting products is prone to various defects that can compromise their performance and reliability.

Table 1: Types and Applications of Casting Products in MTUs

| Material | Application | Characteristics |

|---|---|---|

| Aluminum Castings | Transmission systems (e.g., gearboxes) | Good strength and toughness |

| Steel Castings | Traction systems, braking systems, coupling systems, bogies | High strength, high toughness, good wear resistance |

| Iron Castings | Brake cylinder assemblies, brake caliper assemblies | Good wear resistance and corrosion resistance |

2. Case Studies of Casting Defects

2.1 Original Casting Defects

2.1.1 Pre-crack Defects

A case study involves a mounting bracket made of cast gray iron for an MTU. Macroscopic examination of the fracture surface revealed a brittle fracture with no macroscopic plastic deformation. The fracture surface exhibited a “coarse porcelain-like” appearance with reddish-brown coverings, indicating the presence of original pre-cracks from the casting stage. SEM and EDS analysis confirmed that the reddish-brown covering was sandbox interior coating, suggesting that the part had pre-existing cracks before use.

Table 2: Pre-crack Defect Analysis

| Observation | Finding |

|---|---|

| Macroscopic appearance | Brittle fracture, no plastic deformation |

| Color of covering | Reddish-brown |

| SEM/EDS analysis | Sandbox interior coating |

2.1.2 Shrinkage Defects

Another case involves a coupler jaw made of cast iron for an MTU. The macroscopic fracture morphology showed a U-shaped groove at the crack initiation site, which was the area with the smallest effective cross-sectional area. SEM analysis revealed multiple porosity and shrinkage defects in the crack initiation zone and the core, indicating original shrinkage defects.

Table 3: Shrinkage Defect Analysis

| Observation | Finding |

|---|---|

| Crack initiation site | U-shaped groove |

| SEM analysis | Multiple porosity and shrinkage defects |

2.1.3 Cold Lap Defects

A third case involves an adjustment sleeve made of 07Cr19Ni10 cast stainless steel for a windscreen tie bar system. The external appearance and defect location showed an original fracture surface with an oxidized rusty appearance, indicating a casting cold lap defect.

Table 4: Cold Lap Defect Analysis

| Observation | Finding |

|---|---|

| Defect appearance | Oxidized rusty appearance |

| Material | 07Cr19Ni10 cast stainless steel |

2.1.4 Hot Crack Defects

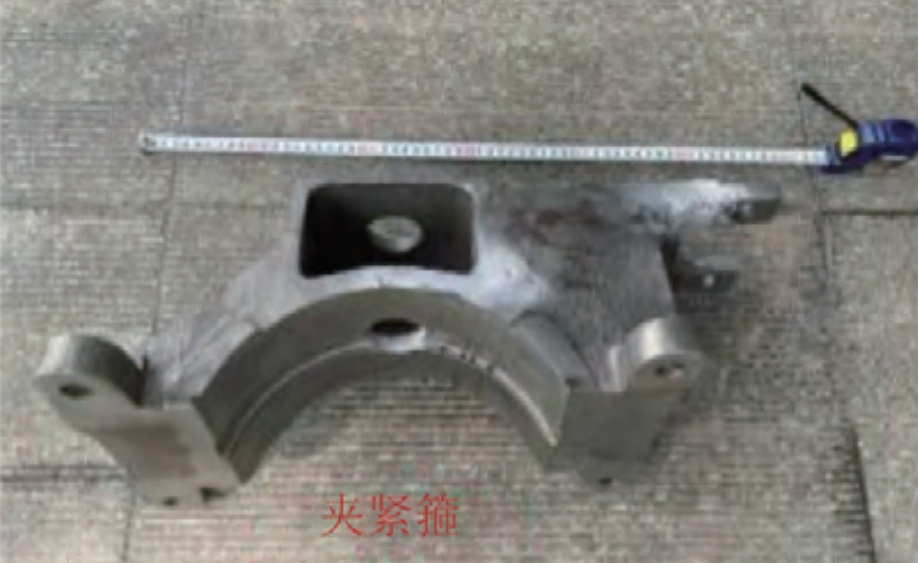

A clamping hoop made of cast steel exhibited magnetic particle inspection results showing three areas with intermittent and tortuous magnetic traces. Microscopic examination of these areas revealed cracks with decarburization on both sides, confirming hot cracks from the casting process.

Table 5: Hot Crack Defect Analysis

| Observation | Finding |

|---|---|

| Magnetic particle inspection | Three areas with magnetic traces |

| Microscopic examination | Cracks with decarburization |

2.2 Heat Treatment Process Defects

A lower arm bracket made of cast aluminum alloy showed no obvious plastic deformation at the fracture site. Microscopic examination revealed a porous defect at the core of the casting, with a brittle fracture characteristic. The microstructure of the bracket was in an unmodified state, with needle-like eutectic silicon cutting through the matrix continuity, leading to brittle fracture under impact loading.

Table 6: Heat Treatment Defect Analysis

| Observation | Finding |

|---|---|

| Fracture characteristic | Brittle fracture |

| Microstructure | Unmodified state, needle-like eutectic silicon |

2.3 Defects Arising from Welding Repairs

A clamping hoop made of E260-450-MS cast steel exhibited irregularly distributed pit-like defects on the assembly surface. Microscopic examination showed welding heat-affected zones at the bottom of the pits, with multiple microcracks on the surface. These defects were caused by poor fusion between the locally welded repair metal and the base material due to improper welding parameters.

Table 7: Welding Repair Defect Analysis

| Observation | Finding |

|---|---|

| Defect location | Assembly surface |

| Microscopic examination | Poor fusion, microcracks |

2.4 Defects from Inadequate Machining

An axle box cover made of GE230N cast steel showed crack-like defects with a depth of approximately 0.54 mm. The cracks originated without original casting defects, and no oxidation or decarburization was observed on either side. SEM examination of the fracture surface revealed fatigue stripes, indicating fatigue fracture. This defect was caused by stress concentration at the variable cross-section transition after casting, leading to fatigue crack initiation and propagation under alternating loads during service.

Table 8: Machining Defect Analysis

| Observation | Finding |

|---|---|

| Crack depth | ~0.54 mm |

| SEM examination | Fatigue stripes |

| Cause | Stress concentration, alternating loads |

3. Analysis and Discussion

3.1 Impact of Original Casting Defects

Original casting defects adversely affect the structural integrity, appearance quality, and service performance of casting products. Defects such as porosity and cracks weaken the structural integrity, reducing load-bearing capacity and service life. Surface defects degrade the aesthetic appeal and market acceptance of the product. Moreover, these defects impair mechanical properties like wear resistance, corrosion resistance, and fatigue strength, compromising reliability and safety.

Table 9: Impact of Original Casting Defects

| Aspect | Impact |

|---|---|

| Structural integrity | Reduced load-bearing capacity, shortened service life |

| Appearance quality | Aesthetic degradation, reduced market acceptance |

| Service performance | Impaired mechanical properties, reduced reliability and safety |

3.2 Impact of Poor Microstructure

Poor microstructure leads to decreased mechanical properties such as tensile strength, yield strength, and hardness. Uneven crystal structure and chemical composition distribution contribute to plastic deformation and fracture during use, affecting service life and safety performance. Additionally, poor microstructure affects physical properties like thermal expansion coefficient, thermal conductivity, and specific heat capacity, potentially causing performance instability in specific environments. Chemical properties like corrosion resistance and oxidation resistance also suffer, accelerating corrosion and oxidation, further reducing service life and reliability.

Table 10: Impact of Poor Microstructure

| Property | Impact |

|---|---|

| Mechanical properties | Decreased tensile strength, yield strength, hardness |

| Physical properties | Decreased thermal expansion coefficient, thermal conductivity |

| Chemical properties | Reduced corrosion resistance, oxidation resistance |

3.3 Impact of Uneliminated Original Defects After Welding Repairs

Uneliminated original defects after welding repairs further degrade mechanical properties, compromise seal integrity, and reduce corrosion resistance and fatigue life. These defects reduce the effective load-bearing area of welds, exacerbate stress concentration, and facilitate fracture or plastic deformation under load. For pressure vessels and pipelines requiring sealing, uneliminated defects like porosity and incomplete penetration can lead to leakage accidents. Moreover, these defects act as initiation sites for fatigue cracks, accelerating crack propagation and ultimately causing fatigue fracture under alternating loads.

Table 11: Impact of Uneliminated Original Defects After Welding Repairs

| Aspect | Impact |

|---|---|

| Mechanical properties | Further degradation |

| Seal integrity | Compromised |

| Corrosion resistance and fatigue life | Reduced |

3.4 Impact of Defects Arising from Inadequate Machining

Defects resulting from inadequate machining during the manufacturing process of casting products for motor train units (MTUs) have significant implications on both the mechanical properties and dimensional accuracy of the final products. These defects, which can manifest as cracks, scratches, pits, or other imperfections on the surface or within the interior of the casting, disrupt the continuity of the material. This disruption leads to a reduction in critical mechanical properties such as tensile strength and yield strength.

In components that are subjected to high stress or loads, such as those found in high-speed train bogies, couplers, traction systems, and braking systems, these machining defects can be particularly problematic. They can act as stress concentrators, increasing the likelihood of fracture or failure during service. Such failures can have catastrophic consequences, including derailments, collisions, and other accidents, thereby compromising the safety and reliability of the MTU.

Furthermore, inadequate machining can also result in dimensional inaccuracies that exceed the allowable tolerances specified for the casting. This can affect the assembly and service performance of the component, leading to poor fit and function within the overall system. In extreme cases, dimensional inaccuracies can render the component unusable, resulting in costly delays and replacements.

To mitigate the impact of machining defects, manufacturers must adhere to strict quality control measures during the machining process. This includes the use of precision tooling, proper lubrication, and regular inspections to ensure that the casting is machined to the required specifications. Additionally, post-machining inspection techniques such as magnetic particle inspection (MPI) or ultrasonic testing (UT) can be employed to detect and identify any defects that may have been introduced during the machining process.

In conclusion, defects arising from inadequate machining of casting products for MTUs have a profound impact on the mechanical properties and dimensional accuracy of the final products. By implementing rigorous quality control measures and post-machining inspection techniques, manufacturers can minimize the occurrence of these defects and ensure the safety and reliability of the MTU components.