Abstract

The structure and technical specifications of shell castings for pavement mechanical vibrators. Addressing issues such as slag inclusion, shrinkage porosity, low process yield, and high sand-to-iron ratio in the original top-pouring process, we propose enhancements and optimizations. By adopting a middle-bottom pouring riser process and integrating various systems, we have significantly improved casting quality, reduced production costs, and ensured compliance with customer requirements.

Keywords: Nodular Cast Iron; Shell Casting; Casting Process

1. Introduction

Shell castings are crucial components in pavement mechanical vibrators, utilizing eccentric weights to generate working pressure through rotational centrifugal force. These castings must possess superior impact resistance, high toughness, and meet stringent quality standards due to their harsh operating environments. This paper focuses on optimizing the casting process for these shells to enhance quality, reliability, and safety.

2. Structural Characteristics and Technical Requirements of Shell Castings

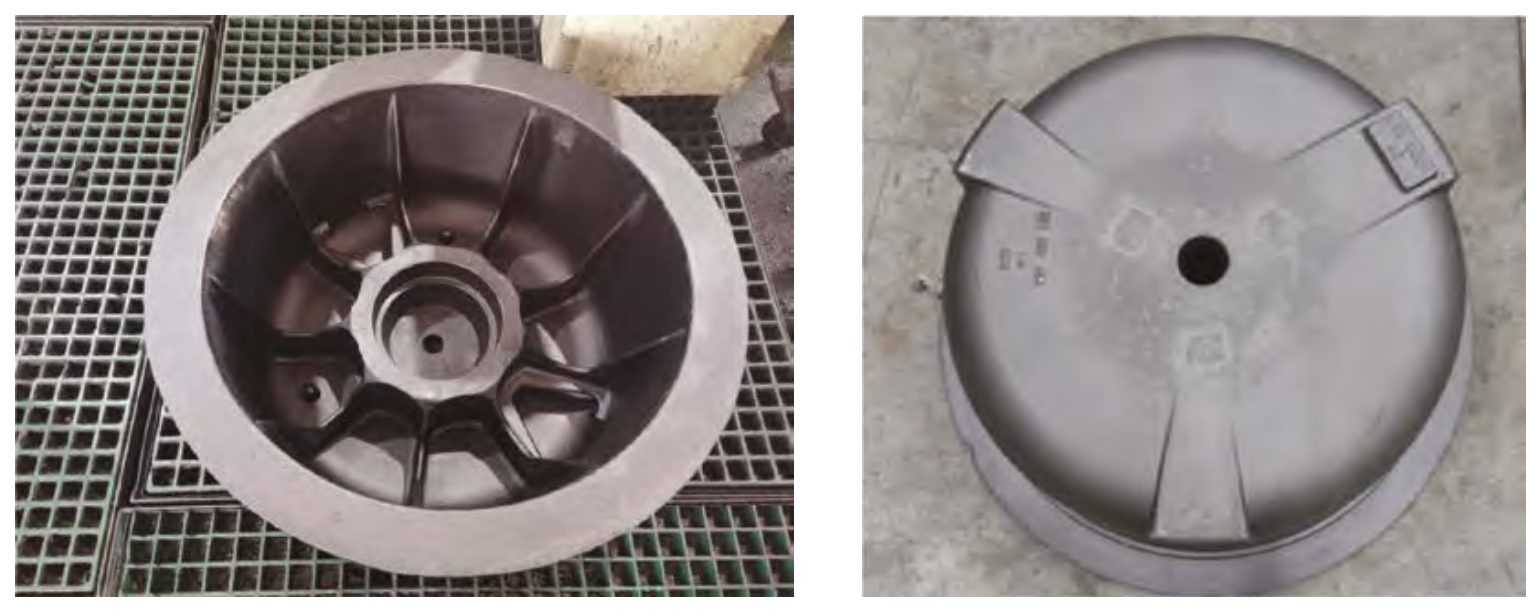

2.1 Structural Characteristics

The shell casting features a complex basin-shaped structure with an outer flange at the top and a hub with reinforcing ribs at the bottom of the inner cavity. The casting material is grade 1E0356 (QT450-12), weighing 152 kg with maximum dimensions of φ900 mm × 500 mm. The primary wall thickness is 15 mm, with a maximum of 40 mm.

Table 1. Chemical Compositions of Shell Casting (Mass Fraction, %)

| Element | Range |

|---|---|

| C | 3.5 ~ 3.9 |

| Si | 2.4 ~ 2.8 |

| Mn | ≤ 0.4 |

| Cr | ≤ 0.08 |

| Ti | ≤ 0.025 |

| Mg | 0.025 ~ 0.055 |

| P | ≤ 0.05 |

| S | ≤ 0.02 |

Table 2. Mechanical Properties of Shell Castings

| Property | Range |

|---|---|

| Tensile Strength/MPa | ≥ 415 |

| Yield Strength/MPa | ≥ 275 |

| Elongation after Fracture/% | ≥ 7 |

| Hardness (HBW) | 156 ~ 217 |

2.2 Metallurgical Structure

The matrix structure consists of ≤ 10% pearlite, ≤ 1% carbide, and lamellar graphite ≤ 0.35 mm. The graphite type is spherical, with a grade of 5 ~ 8 and a spheroidization rate ≥ 90%.

3. Original Process and Existing Issues

3.1 Molding Process

The original process employed furan self-hardening resin sand molding with a standard sandbox size of 1400 mm × 1200 mm. A top-pouring dispersed gating system was used, with the shell flange facing upwards. The gating system dimensions were specifically designed to ensure adequate metal flow. However, issues such as shrinkage porosity, slag inclusion, high sand-to-iron ratio, and low process yield were observed.

Figure 1. Original Shell Casting Process with Gating and Risers

(Insert image of the original process here)

3.2 Melting Process

High-quality raw materials were used, including high-purity pig iron and clean, pressed scrap steel. The chemical composition of the molten iron was strictly controlled. However, the original process suffered from high pouring temperatures and turbulence, leading to defects.

4. Process Improvement and Production Verification

4.1 Process Improvement

To address the issues, we adopted a middle-bottom pouring riser process and optimized the gating system using MAGMA casting simulation software.

Figure 2. Simulation of Improved Shell Casting Process

(Insert image of the improved process simulation here)

Table 3. Comparison of Gating System Dimensions

| Original Process | Improved Process |

|---|---|

| ΣS直∶ΣS横∶ΣS内 = 1∶1.75∶1.3 | ΣS直∶ΣS横∶ΣS内 = 1∶1.1∶0.9 |

| Sprue section φ60 mm | Sprue section φ60 mm |

| Cross sprue section | Cross sprue section |

| (40/50 mm × 55 mm) | (35/40 mm × 40 mm) |

| Ingate section | Ingate section φ40 mm (2) |

| (40/45 mm × 10 mm × 5) |

4.2 Combination Shell Mold and Additional Components

The upper and lower shell molds were combined to form a composite mold, equipped with filters, insulation risers, sprue pipes, and exhaust ropes. This integration facilitated easy combination, molding operations, and improved metal filtration, pouring stability, and feeding efficiency.

Figure 3. Improved Shell Casting Process with Composite Mold

(Insert image of the improved process with composite mold here)

4.3 Material and Melting Refinements

A lanthanum-containing ferrosilicon magnesium alloy was used as the nodulizer, reducing shrinkage porosity tendencies. High-silicon barium-silicon inoculants were employed for pre- and in-mold inoculation to enhance the spheroidization rate and mechanical properties.

5. Production Verification and Results

5.1 Quality Improvement

The optimized process significantly reduced defects such as slag inclusion and shrinkage porosity. X-ray inspections showed grade-one quality, with mechanical properties and metallurgical structures fully meeting customer specifications.

Table 4. Mechanical Properties and Metallurgical Structure of Improved Shell Castings

| Property | Measured Value | Specification |

|---|---|---|

| Tensile Strength/MPa | 455 | ≥ 415 |

| Yield Strength/MPa | 308 | ≥ 275 |

| Elongation after Fracture/% | 18.5 | ≥ 7 |

| Hardness (HBW) | 178 | 156 ~ 217 |

| Pearlite (%) | 3 | ≤ 10 |

| Carbide (%) | ≤ 1 | ≤ 1 |

| Lamellar Graphite (mm) | ≤ 0.20 | ≤ 0.35 |

| Graphite Grade | 6 | 5 ~ 8 |

| Spheroidization Rate (%) | ≥ 90 | ≥ 90 |

5.2 Economic Benefits

The process improvements led to increased process yield from 62% to 80% and reduced the sand-to-iron ratio from 7:1 to 2.5:1. The overall reject rate decreased from 8.0% to 2.0%, significantly lowering production costs and enhancing technical and economic benefits.

6. Conclusion

6.1 Enhanced Casting Quality

The optimized middle-bottom pouring riser process, combined with an integrated system, significantly improved casting quality by eliminating defects, increasing process yield, and reducing the sand-to-iron ratio.

6.2 Improved Material Properties

The use of lanthanum-containing nodulizers and multiple inoculations stabilized the nodularization process, yielding high-quality ductile iron shell castings.

6.3 Cost Reduction

Structural optimizations of the molding sandboxes further reduced sand consumption and pouring-related gas emissions, preventing porosity defects and lowering overall production costs.

In summary, the optimizations implemented in the shell casting process for pavement mechanical vibrators have led to significant improvements in casting quality, reduced production costs, and enhanced economic benefits, ensuring full compliance with customer requirements.