Abstract: This article delves into the ultrasonic testing technology employed for detecting embedded defects in steel castings for large butterfly valves. By integrating the unique acoustic characteristics of steel castings into the detection process, suitable single/dual-crystal longitudinal wave straight probes are selected through comparative experiments. The key points of the detection process for both single-crystal and dual-crystal straight probes are elaborated. Based on testing experience, the waveform characteristics and mechanisms of four typical clustered internal defects commonly found in large butterfly valve steel castings are summarized. Practice has proven that the composite testing process using single/dual-crystal longitudinal wave straight probes, as a practical non-destructive testing technology, can ensure that the steel castings of butterfly valves entering the precision machining process meet the corresponding quality requirements.

1. Introduction

Large steel castings, due to their larger size, complex production processes, and variations in production equipment and conditions among different enterprises, often exhibit a higher variety and number of internal defects compared to smaller castings. These defects, such as pores, cracks, laminations, and inclusions generated during the casting process of steel castings, not only affect product quality but may also lead to a decline in mechanical and physical properties during equipment operation, potentially causing equipment failure and impacting production safety.

In the current manufacturing process of large butterfly valves, technical requirements for the valve body and disc mainly include surface macro examination (VT), mechanical performance indicators, material chemical composition, heat treatment requirements, as well as MT, PT, and UT testing reports. The detection of embedded defects in the machined surfaces of butterfly valve steel castings (primarily including flanges, inner chambers, discs, etc.) primarily relies on ultrasonic testing technology. Especially before the precision machining of butterfly valve castings, applicable and rigorous ultrasonic testing processes are adopted to detect and identify defects, followed by repair and re-inspection, ultimately ensuring the castings enter the precision machining process in a qualified state.

The steel castings for hydropower butterfly valves share similar acoustic characteristics with other steel pieces, characterized by an internal structural feature of coarse grains and non-dense microstructures due to the long solidification and cooling time of local molten steel and slower cooling rates. The severe attenuation and scattering of ultrasonic waves caused by coarse grains in steel castings are unavoidable issues in the formulation of flaw detection processes. Additionally, the detection requirements for near-surface defects on machined surfaces make it often impossible to complete such defect detection using only single-crystal straight probes. Therefore, these issues should be fully considered when formulating the testing process, and suitable probe parameters (material, type, frequency) and testing methods should be selected through necessary actual measurements and comparisons to achieve relatively ideal detection results.

2. Ultrasonic Testing Process for Steel Castings of Butterfly Valves

2.1 Testing Equipment

This study utilizes the HS-II digital ultrasonic flaw detector, with a vertical linearity error of no more than 3%, a horizontal linearity error of no more than 0.1%, a signal bandwidth of 0.5 to 30 MHz, and a gain range of 0 to 120 dB.

2.2 Selection of Single-Crystal Longitudinal Wave Straight Probe Parameters

The attenuation of sonic energy during ultrasonic testing of steel castings primarily stems from interface reflection and acoustic wave absorption caused by coarse grains. The higher the probe frequency, the more severe the ultrasonic attenuation. Simultaneously, the grass-like noise interference formed by irregular reflections at grain boundaries during flaw detection also affects the signal-to-noise ratio of ultrasonic testing. Therefore, lower-frequency probes are preferable for ultrasonic testing of steel castings.

In practical inspection, the accuracy and quality of ultrasonic testing of steel castings are influenced by a combination of factors, and whether the detection process can achieve optimal results should be tested and verified on-site. During process debugging, acoustic parameters such as sound velocity, acoustic impedance, and material attenuation coefficient need to be measured to facilitate the selection of appropriate probe parameters (frequency, crystal size), etc. This project adopts single-crystal straight probes of different frequencies to conduct comparative tests on simulated test blocks within different thickness ranges. By calculating the attenuation coefficient, comparing the equivalent of flat-bottomed hole defects, and contrasting the signal-to-noise differences during testing, combined with the testing equipment conditions, the parameter selection range for single-crystal straight probes for ultrasonic testing of this butterfly valve steel casting is formulated, as shown in Table 1.

Table 1: Single-Crystal Straight Probe for Inspection of Butterfly Valve Steel Casting

| Steel Casting Thickness (mm) | Nominal Frequency of Single-Crystal Longitudinal Wave Straight Probe (MHz) | Diameter of Circular Crystal Plate (mm) |

|---|---|---|

| 50–100 | 3.0–3.5 | ϕ20–ϕ30 |

| 100–200 | 2.5–3.0 | ϕ20–ϕ30 |

| 200–400 | 2.0–2.5 | ϕ20–ϕ30 |

| 400–600 | 1.5 | ϕ20–ϕ30 |

2.3 Selection of Dual-Crystal Straight Probes

For the detection of buried defects in the near-surface and thin-walled areas of this butterfly valve steel casting, dual-crystal straight probes are employed.

3. Detection Process and Defect Analysis

3.1 Detection Process

The ultrasonic testing process for steel castings of large butterfly valves mainly includes pre-testing preparations, calibration of the flaw detector, scanning and detection, defect evaluation, and record keeping.

Pre-testing preparations involve cleaning the test surface to remove rust, oxide scale, grease, and other impurities, ensuring good coupling between the probe and the test piece. The flaw detector is calibrated using reference blocks to determine the sound velocity, beam angle, and detection sensitivity. Scanning and detection are conducted using grid scanning or linear scanning to ensure comprehensive coverage of the detection area. Defect evaluation involves determining the location, size, and nature of defects based on the waveform characteristics, amplitude, and phase of the ultrasonic echo signal. Finally, detailed records of the detection results are kept.

3.2 Typical Defect Waveform Characteristics

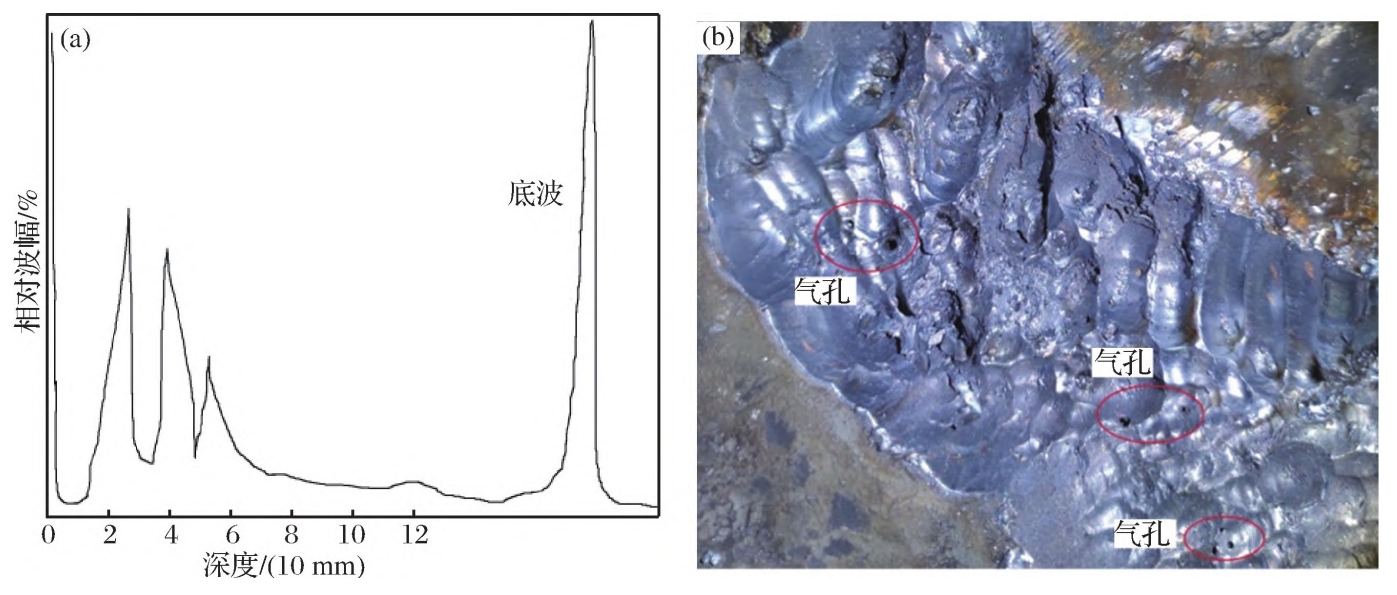

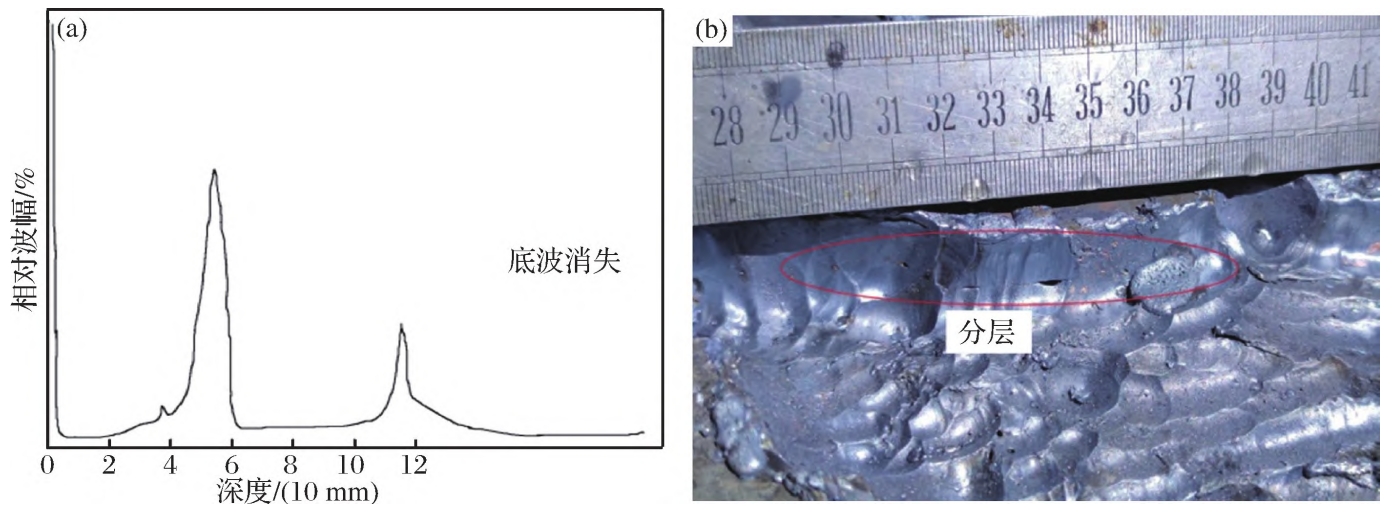

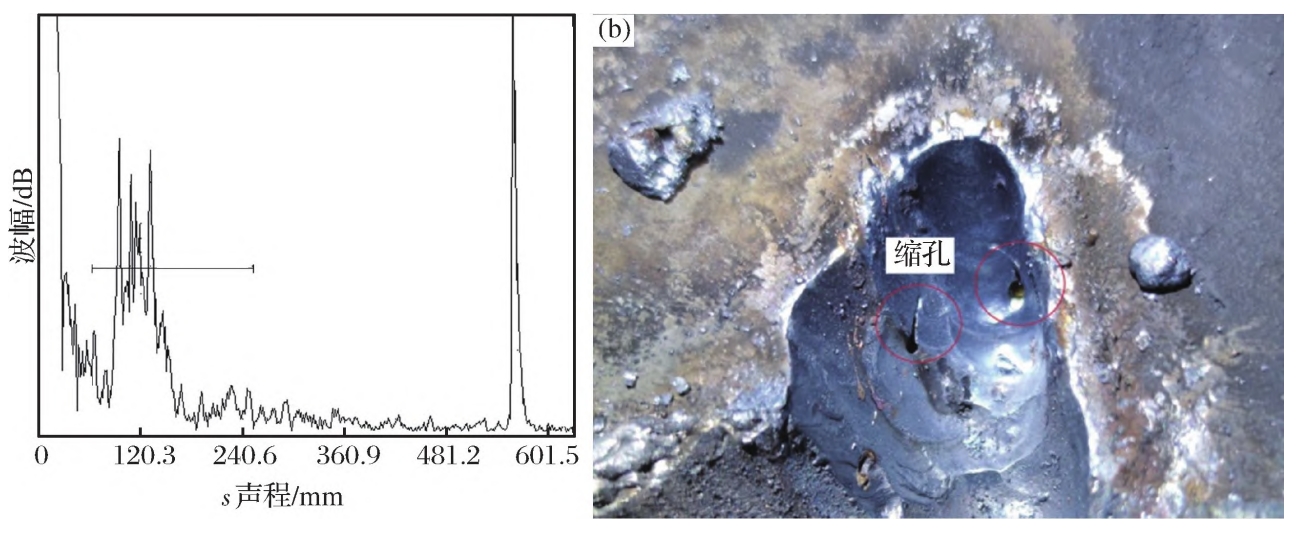

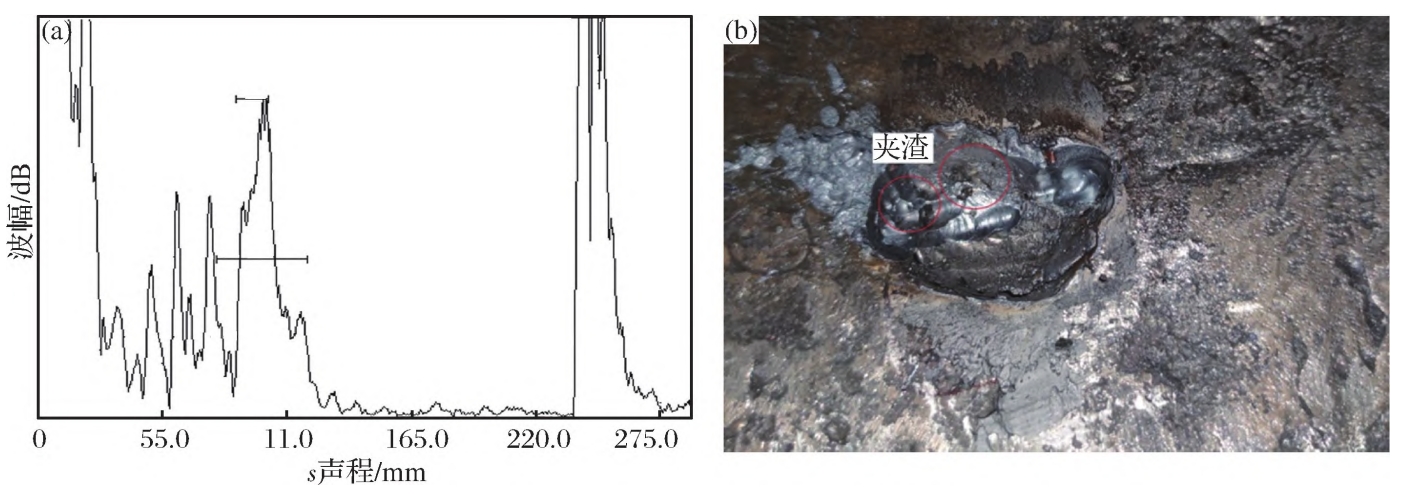

Based on extensive testing experience, four typical clustered internal defects commonly found in large butterfly valve steel castings have been summarized, each with distinct waveform characteristics.

Table 2: Typical Defect Waveform Characteristics in Butterfly Valve Steel Casting

| Defect Type | Waveform Characteristic | Possible Causes |

|---|---|---|

| Porous Defect | Low-amplitude, dense echoes with good continuity | Gas entrapment during casting process |

| Crack Defect | High-amplitude, waveform with sharp peaks and troughs, often accompanied by multiple reflections | Stress concentration, thermal cracking, or mechanical impact |

| Lamination Defect | Waveform with alternating high and low amplitudes, parallel to the detection surface | Incomplete fusion between layers during casting |

| Inclusion Defect | Scattered echoes of varying amplitudes, often irregular in shape | Non-metallic inclusions such as oxides, sulfides, or silicates |

4. Discussion

The ultrasonic testing technology for steel castings of large butterfly valves presented in this article effectively addresses the challenges posed by the coarse grains and non-dense internal structures of steel castings. By selecting appropriate single/dual-crystal longitudinal wave straight probes and formulating detailed detection processes, high-quality detection results can be obtained.

The use of dual-crystal straight probes significantly enhances the detection capability for near-surface defects, overcoming the limitations of single-crystal straight probes. Meanwhile, the comprehensive analysis of defect waveform characteristics provides important information for defect evaluation and repair decisions.

5. Conclusion

In summary, the composite testing process using single/dual-crystal longitudinal wave straight probes is proven to be an effective non-destructive testing technology for steel castings of large butterfly valves. It ensures that the steel castings meet the corresponding quality requirements before entering the precision machining process, thereby improving product reliability and safety.

Future research can further explore the optimization of probe parameters and detection processes to improve detection accuracy and efficiency, as well as the application of advanced signal processing techniques to enhance defect identification capabilities.