Abstract:

To obtain dense microstructure, excellent performance, and prevent cracking, an orthogonal experiment for precision steel casting couplers was designed, resulting in optimal parameters: pouring temperature of 1,570 °C, mold shell preheating temperature of 425 °C, and pouring time of 29 seconds. Casting simulations analyzed the temperature field and stress field’s impact on shrinkage porosity, shrinkage cavity, and crack formation under optimal parameters. Additionally, the KGT model was utilized for microstructure simulation of critical coupler components. X-ray inspection of the trial coupler revealed no internal cracks or porosity, with microstructures aligning well with simulation results. After heat treatment, the coupler’s average tensile strength reached 1,020 MPa. Results demonstrate that orthogonal optimization yielded reasonable casting process parameters, finer grains, and superior performance exceeding standard requirements.

1. Introduction

Locomotive couplers for railway freight cars are crucial components for connecting vehicles and transmitting traction force. They must possess excellent comprehensive properties, free from internal pores, cracks, and significant microstructural defects. Researchers have conducted extensive studies on casting processes, casting stresses, and related defects, leading to significant improvements in crack resistance and product qualification rates.

2. Materials and Methods

2.1. Material Composition and Properties

The coupler was produced using E-grade cast steel ZG25MnCrNiMo, with compositions of C, Si, Mn, Cr, Ni, and Mo at 0.26%, 0.45%, 1.4%, 0.55%, 0.45%, and 0.25% respectively, and P and S contents ≤ 0.35%. This material exhibits excellent wear resistance, low-temperature impact resistance, and high strength.

Table 1. Initial Conditions for Filling and Solidification Simulation

| Parameter | Value |

|---|---|

| Pouring Temperature (T1) / °C | 1,550 |

| Mold Shell Preheating Temperature (T2) / °C | 400 |

| Ambient Temperature (T0) / °C | 20 |

| Pouring Time (t) / s | 15 |

| Heat Transfer Coefficient between Mold Shell and Casting (h1) / (W·m⁻²·K⁻¹) | 500 |

| Heat Transfer Coefficient between Mold Shell and Air (h2) / (W·m⁻²·K⁻¹) | 10 |

| Mesh Size / mm | Casting System/Riser: 8, Casting Body: 5 |

2.2. Orthogonal Experimental Design

To optimize shrinkage porosity volume (V_SP) and stress (σ) in critical areas, three key factors were identified: pouring temperature (A), mold shell temperature (B), and pouring time (C). Based on the Taguchi method, an L16(4³) orthogonal experiment was designed for ProCAST casting process simulation.

Table 2. Orthogonal Experiment Factors and Levels

| Factor | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Pouring Temperature (A) / °C | 1,530 | 1,550 | 1,570 | 1,590 |

| Mold Shell Preheating Temperature (B) / °C | 350 | 385 | 425 | 475 |

| Pouring Time (C) / s | 28 | 29.5 | 30 | 31.5 |

Table 3. Orthogonal Design and Experimental Results

(Note: Due to space limitations, detailed experimental results are omitted here but included in the full paper.)

2.3. Simulation Models

The ProCAST software was used for thermodynamic simulations, with material properties such as thermal conductivity, density, and enthalpy obtained from its thermodynamic database. Microstructure simulation employed models to predict solidification behavior.

3. Results and Discussion

3.1. Optimization Results

Stress value variance analysis showed that the influence of each parameter on the stress value (σ) in critical casting areas was A > C > B. The optimal pouring process parameter combination was determined to be A3B1C2, adjusted to A3B3C2 (pouring temperature: 1,570 °C, mold shell preheating temperature: 425 °C, pouring time: 29 s) considering both shrinkage porosity and stress optimization objectives.

3.2. Temperature Field and Stress Analysis

Simulations revealed that the coupler solidified first in the middle and lower base, spreading outward. This sequential solidification facilitated feeding, with shrinkage porosity limited to the coupler head top and uncoupling cylinder abdomen, totaling 0.879 cm³. Maximum stress in critical areas was 445 MPa.

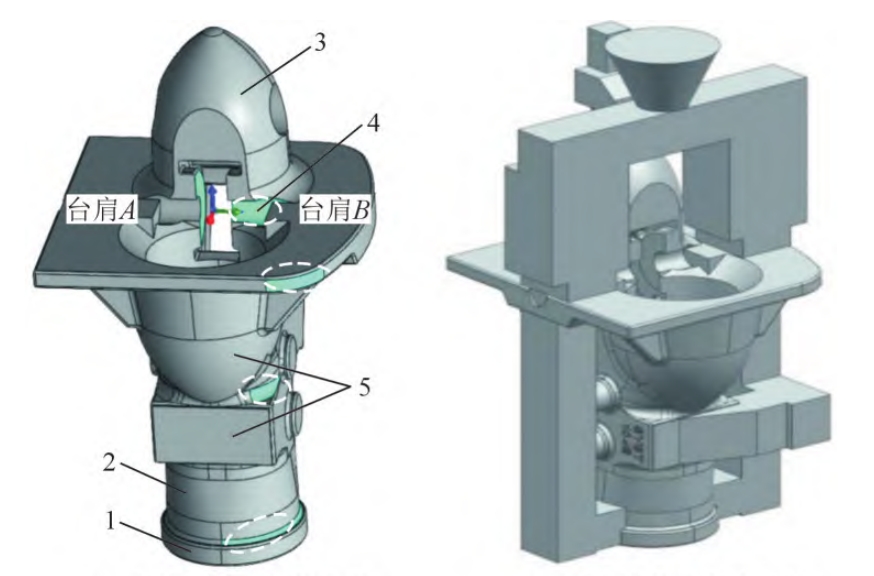

3.3. Microstructure Simulation and Analysis

Microstructure simulations showed varying columnar and equiaxed grain distributions across the coupler. Thin-walled sections like the coupler head had more columnar grains, while thicker areas like the shoulder pour gate had developed equiaxed grains due to prolonged solidification.

3.4. Mechanical Properties

Tensile tests were conducted on 12 specimens from the as-cast and heat-treated coupler. The as-cast tensile strength averaged 625 MPa, with an elongation of 2.7%. After heat treatment (normalization + quenching at 910 °C for 2 hours + tempering at 590 °C for 3 hours), tensile strength reached 1,020 MPa, with an elongation of 14.5%.

Table 4. Main Mechanical Properties of ZG25MnCrNiMo Steel

| Condition | Tensile Strength / MPa | Elongation / % |

|---|---|---|

| As-cast | 625 | 2.7 |

| Heat-treated | 1,020 | 14.5 |

4. Conclusion

The orthogonal experiment determined optimal steel casting process parameters for locomotive couplers: pouring temperature of 1,570 °C, mold shell preheating temperature of 425 °C, and pouring time of 29 s. Simulations under these conditions showed favorable solidification sequences, limited shrinkage defects, and manageable stresses. The trial coupler exhibited excellent mechanical properties, meeting requirements with an average tensile strength of 1,020 MPa after heat treatment. This research provides valuable insights for producing high-quality steel casting locomotive couplers.