Abstract: In the context of the production of traditional steel castings, the lack of a scientific and meticulous ladle management system has become a prominent issue. This paper introduces and discusses the common problems encountered in the use of ladles and their corresponding solutions. By selecting suitable refractory materials, strictly controlling ladle process management, monitoring internal ladle temperature, and optimizing baking process parameters, the quality of liquid steel and, consequently, steel castings can be significantly improved. This comprehensive approach ensures the production of high-quality steel castings.

Keywords: high-quality steel castings; ladle management; refractory materials; baking time

1. Introduction

Steel castings serve as a crucial component in the equipment manufacturing industry, supporting the development of various main machines and key technological equipment. They are also an important indicator of a country’s overall national strength. Despite remarkable achievements in steel casting production in China, there are still gaps compared to developed countries. Enhancing the quality of steel castings is essential to compete in the global market. This paper focuses on the critical role of ladle management in ensuring the quality of high-end steel castings.

2. Current Status and Issues of Ladle Management

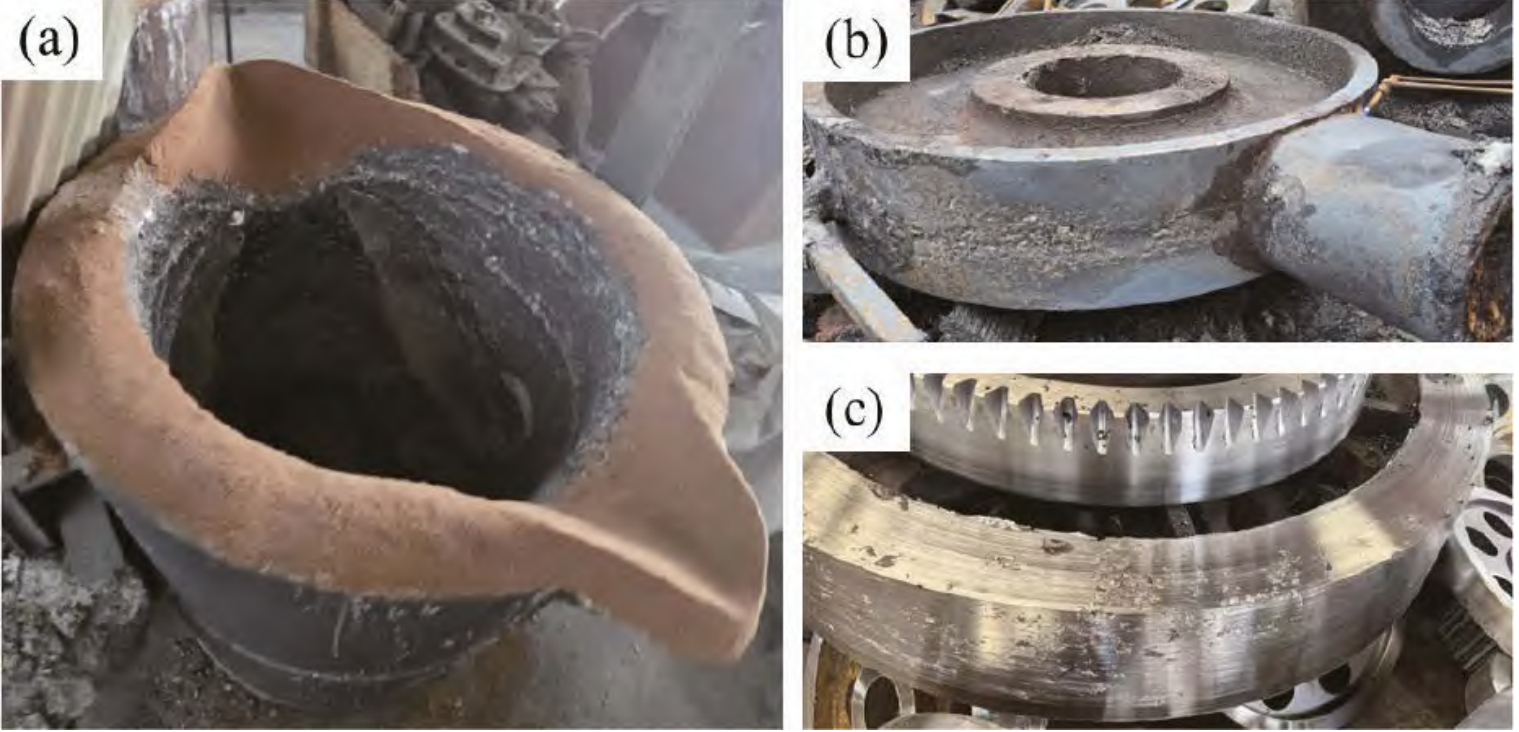

2.1 Current Status of Ladle Use and Management

Currently, many enterprises in China, especially small and medium-sized ones, continue to use quartz sand, clay, and water glass to make ladles manually. Some enterprises use packaged materials, while a handful use teapot-style ladles primarily for small castings. Higher-standard enterprises and large state-owned enterprises typically use bottom-pouring ladles, divided into stopper rod and slide gate types, constructed with ladle bricks such as clay bricks and high-alumina bricks. Large enterprises tend to have more refined ladle management due to their stricter regulations.

Table 1. Types of Ladles

| Type | Description |

|---|---|

| Tilting | Ladle can be tilted to pour steel liquid |

| Bottom-pouring | Steel liquid flows out from the bottom |

| Teapot | Resembles a teapot, used for small castings |

2.2 Existing Problems

Several issues related to ladles can directly impact the quality of steel castings:

- Unstable Raw Material Quality: Use of varying quality refractory materials like clay bricks can result in material debris mixing into the casting.

- Improper Baking: Inadequate baking time or temperature can lead to porosity, while excessive baking can shorten the ladle’s lifespan.

- Masonry Issues: Poor masonry can lead to gaps, causing bricks to fall off and affecting ladle lifespan.

- Improper Tap Temperature Control: Too low can lead to adhesion of slag, while too high can exacerbate erosion.

- Extended Static Time for High-Temperature Steel Liquid: High temperatures for long durations can intensify erosion.

- Improper Pouring Operation: Pouring onto the stopper rod can damage it.

- Quality Issues with Bottom-Pouring Spout and Seating Brick: Poor quality can lead to clogging and dripping.

- Inferior Stopper Rod or Fixing Bolt Material: Can easily break or fail to seal tightly.

- Blocked Argon Blowing Hole: Can affect refining effectiveness.

- Extended Steel Liquid Storage Time: Can cause the stopper rod to jam.

- Improper Gap Control Between Stopper Rod and Seating Brick: Can lead to bending of the stopper rod after baking.

- Inadequate Ladle Cleaning: Residual slag can mix into the steel liquid, affecting purity.

3. Improvement Methods and Effects

3.1 Improvement Methods

To address the aforementioned issues, meticulous management strategies should be implemented, with each ladle having a detailed record maintained by specialized personnel. By inspecting and correcting deviations before the pouring process, we can ensure high-quality steel castings.

- Strict Raw Material Control: Opt for high-quality alumina bricks, considering both price and quality. Graphite stopper heads and seating bricks can further enhance ladle performance.

Table 2. Physical and Chemical Indicators of High-Alumina Refractory Bricks

| Brick Type & Grade | Al2O3 Content (%) ≥ | Refractoriness (℃) ≥ | Softening Point under Load (0.20 MPa) (℃) ≥ | Linear Change after Refiring (%) | Apparent Porosity (%) ≤ | Cold Compressive Strength (MPa) ≥ | Standards |

|---|---|---|---|---|---|---|---|

| General-purpose High-Alumina Brick IZ-75 | 75 | 1790 | 1520 | +0.1 to -0.4 | 23 | 53.9 | GB/T 2988-2023 |

| IZ-65 | 65 | 1500 | 49.0 | IZ-55 | 55 | 1770 | 44.1 |

| IZ-48 | 48 | 1750 | 39.2 | ||||

| Steelmaking Furnace Top High-Alumina Brick DL-80 | 80 | 1530 | – | 0.2 to 0.4 | 19 (21) for arch corner | 75 | YB/T 5017-2000 |

| (Additional grades and indicators omitted for brevity) |

- High-Quality Masonry: Ensure tight seams between bricks for higher ladle quality.

- Controlled Tap Temperature and Holding Time: Reduce erosion and prevent contaminants from entering the steel liquid.

- Optimized Baking Time and Temperature: Bake for about half an hour until the ladle turns dark red; excessive baking reduces lifespan.

- Proper Pouring Spout Diameter: For a 20-ton arc furnace, a spout diameter of about 140 mm is suitable.

- Controlled Argon Blowing and Holding Time: Achieve optimal results.

- Thorough Ladle Cleaning: Use an oxygen lance to clean residual steel liquid and slag after each pour, ensuring a flawless standard for high-quality steel castings.

3.2 Improvement Effects

By refining the processes of ladle material selection, masonry, pouring, maintenance, and management, the quality of produced parts significantly improved. For example, in the production of wind turbine locking sleeves, parts produced under meticulous management achieved zero defects upon customer inspection, earning praise.

4. Conclusion

In the production of high-quality steel castings, meticulous ladle management is crucial. Selecting high-quality alumina bricks and graphite materials for stopper rods and heads enhances ladle performance. Precisely controlling baking time, tap temperature, and holding time extends ladle lifespan and reduces inclusions. Thorough ladle cleaning is essential for casting quality. These measures collectively ensure the production of high-quality steel castings.