This article focuses on the cracking problem of the web door opening of the casting crane main beam. It comprehensively analyzes the load on the main beam during the crane’s operation, determines the material’s S-N curve, and conducts static and fatigue strength analyses. By optimizing the original opening structure, the fatigue life of the opening is made consistent with the design life of the main beam. Through years of practical verification, the effectiveness of the optimization is demonstrated, providing valuable experience for the design of the metal structure of casting cranes.

1. Introduction

Casting cranes play a crucial role in steel mills as they are responsible for extracting and pouring molten iron ladles. In the past, due to the relatively low efficiency of steelmaking technology and the infrequent use of cranes, problems such as fatigue cracks at the web door openings of the main beam were not prominent. However, with the development of the steel industry and the improvement of production efficiency, the use frequency of cranes has increased significantly, and the cracking problem at the web door openings has become a key factor restricting the service life of the main beam. Therefore, it is necessary to conduct in-depth research and optimization on this issue.

2. Load Analysis of the Main Beam

2.1 Types of Loads

The loads acting on the main beam of the casting crane mainly include concentrated loads generated by the trolley wheels, uniformly distributed loads from the self-weight, electrical control equipment, and the main beam platform, as well as horizontal inertial loads during the starting and braking of the crane 大车.

| Load Type | Description | |

|---|---|---|

| Concentrated Load | Generated by the rated load and trolley self-weight acting on the trolley wheels when the crane is fully loaded. | |

| Uniformly Distributed Load | Caused by the self-weight of the main beam and the combined action of the platform and electrical control equipment attached to it. | |

| Horizontal Inertial Load | Generated by the inertia of the lifting load and self-weight acting on the main beam when the crane brakes. |

2.2 Example Calculation

Taking a certain 210t casting crane as an example, the rated load is 210t, the trolley self-weight is 90t, the number of wheels is 8, , , the main beam span is 22m, the self-weight of the main beam is 36t, the platform weight is 2.3t, the electrical control equipment weight is 0.5t, , and the running speed of the crane 大车 is 80m/min with 1/4 drive.

3. Strength Analysis of the Main Beam

3.1 Establishment of the Finite Element Model

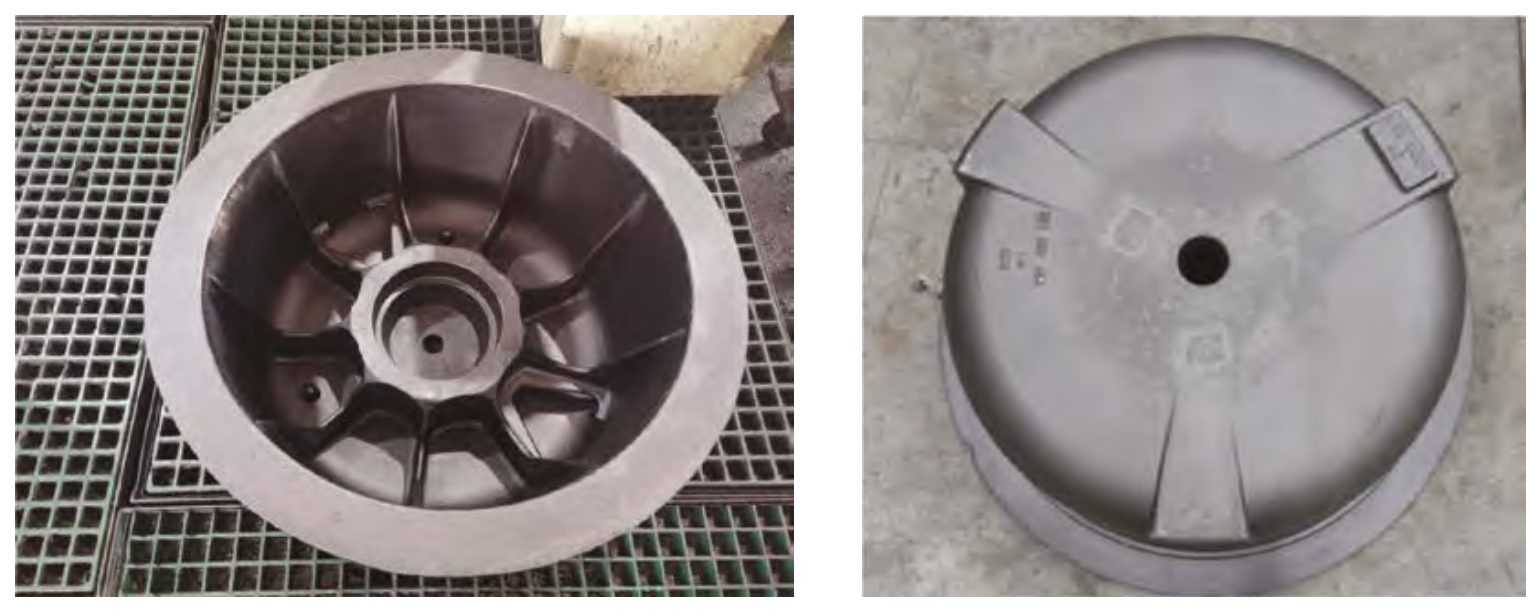

Using SolidWorks software to model the main beam of the crane, the material is Q355B. Simplify the details that have little impact on the analysis results, and use plate-shell elements for meshing. A total of 73,485 elements and 139,692 nodes are obtained.

3.2 Static Strength Analysis

When the trolley is located at 1/4 of the span (usually the position of the web door opening and the crane’s full-load ladle-turning operation), the stress at this section is analyzed. The results show that the stress at the web door opening suddenly increases, reaching a maximum of 152.24MPa, while the surrounding stress is below 115MPa.

3.3 Fatigue Strength Analysis

3.3.1 Determination of the S-N Curve

According to the working level (generally A7 or A8) and stress state level (P4) of the casting crane, and referring to the relevant standards, the S-N curve is established. The data of the S-N curve corresponding to different stress levels are shown in Table 1.

3.3.2 Load Spectrum at the Web Door Opening

Taking the process of the crane transporting the ladle from one time to the next as a working cycle, the load spectrum of the horizontal and vertical loads at the web door opening is established.

3.3.3 Analysis Results

The fatigue life analysis results show that the web door opening will experience fatigue failure after cycles. Under normal working conditions, fatigue cracks will appear at the main beam door opening after about 6 years, which is much lower than the design life of the casting crane (about 15 – 17 years).

4. Optimization of the Web Door Opening Structure

4.1 Stress Concentration Analysis at the Door Opening

From the analysis results of static and fatigue strength, it can be seen that the stress at the rounded corners of the door opening has a sudden change. According to the stress concentration theory, for a plate strip under in-plane bending moment, when a rectangular hole is opened on its centerline, high concentrated stress will be generated at point A near the hole edge. The formula for calculating the concentrated stress at point A is .

4.2 Analysis of the Influence of Opening on Stress Concentration of the Main Beam

It can be seen from the formula that the concentrated stress at point A is related to the height, width, and rounded radius of the opening under the condition of a constant main beam web height. By setting different parameters of hole height and rounded radius and calculating through the finite element method, it is found that the concentrated stress at point A increases with the increase of the opening height and decreases with the increase of the rounded radius. When the rounded radius is 325mm (the hole shape is a long oval), the concentrated stress is the smallest.

4.3 Optimization of the Opening Structure

In engineering design, to reduce stress concentration, the rounded corners should be as large as possible, and the opening height should be as small as possible. At the same time, considering the structural design requirements, the minimum height is set to 1600mm, and the maximum height does not exceed 0.67H according to the equal moment of inertia reinforcement theory. The door opening structure is changed to a long oval shape, and reinforcing bars are arranged on the inner side of the web. After reloading and analyzing the static and fatigue strength, the stress at the door opening is reduced to 115.66MPa, and the fatigue life is increased to times, which is about 15.5 years, consistent with the design life of the main beam. In addition, in order to avoid internal stress caused by the gap between the web and the reinforcement ring during welding, a special welding method is adopted, and the weld is polished to eliminate the residual stress.

5. Conclusion

The optimization of the web door opening structure of the casting crane main beam is of great significance for improving the service life of the crane. Through detailed load analysis, strength calculation, and structural optimization, the fatigue life of the door opening can be effectively improved and made consistent with the design life of the main beam. In future design work, designers should continue to use modern design methods and combine practical experience to continuously optimize the design of crane metal structures to meet the needs of the development of the metallurgical industry.

In the process of writing this article, due to the lack of specific data on the manufacturing process and cost changes before and after optimization, it is recommended to conduct further research in the future to provide more comprehensive reference for the design and application of casting cranes. At the same time, with the continuous development of technology, new materials and design concepts may also bring new opportunities and challenges for the improvement of crane performance. It is necessary to pay close attention to the development trend of the industry and continuously explore and innovate.