Introduction

Investment casting, also known as lost-wax casting, is a manufacturing process that has been used for thousands of years to produce complex and precise metal parts. The process involves creating a wax pattern, coating it with a ceramic shell, melting out the wax, and then pouring molten metal into the cavity left by the wax. One of the most critical steps in this process is the assembly of wax patterns onto a central wax sprue, known as the “wax tree.” Traditionally, this step has been performed manually, which can lead to inconsistencies and inefficiencies. However, recent advancements in automation technology have led to the development of Automatic Wax Pattern Assembly Systems, which promise to revolutionize the investment casting industry.

In this article, we will explore the innovation and application of these automatic systems, focusing on their components, benefits, and potential impact on the industry. We will also provide a detailed analysis of the system’s hardware and software, along with practical examples and case studies.

1. The Traditional Wax Pattern Assembly Process

Before diving into the automated systems, it is essential to understand the traditional wax pattern assembly process. This process involves several manual steps:

- Wax Pattern Preparation: Individual wax patterns are created using injection molding or other methods.

- Assembly: The wax patterns are manually attached to a central wax sprue using a heated tool.

- Inspection: The assembled wax tree is inspected for defects or inconsistencies.

- Coating: The wax tree is coated with a ceramic shell to create the mold.

While this process has been effective for many years, it has several limitations:

- Inconsistencies: Manual assembly can lead to variations in the placement and attachment of wax patterns.

- Labor-Intensive: The process requires skilled labor, which can be costly and time-consuming.

- Quality Control: Manual inspection is prone to human error, leading to potential defects in the final castings.

2. The Need for Automation

Given the limitations of the traditional process, there is a growing need for automation in wax pattern assembly. The primary drivers for this shift include:

- Increased Demand for Precision: Industries such as aerospace and medical devices require extremely precise components, which can be challenging to achieve with manual assembly.

- Cost Reduction: Automation can reduce labor costs and improve efficiency, leading to lower production costs.

- Consistency and Quality: Automated systems can ensure consistent assembly quality, reducing the risk of defects.

- Scalability: Automated systems can handle higher volumes of production, making them ideal for large-scale manufacturing.

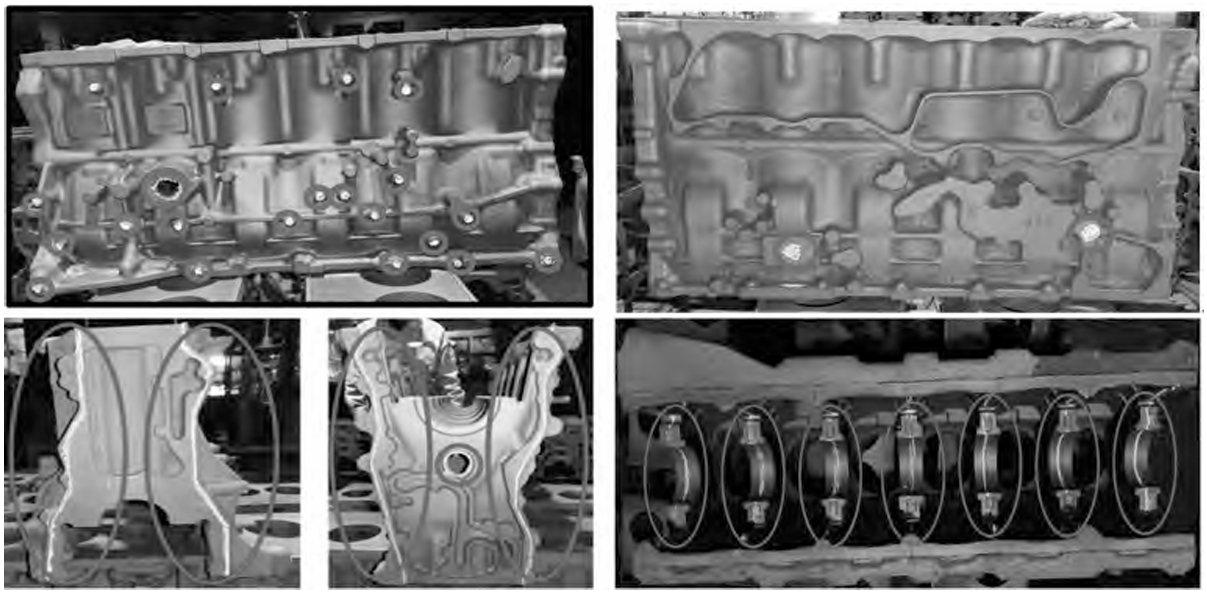

3. Components of an Automatic Wax Pattern Assembly System

An Automatic Wax Pattern Assembly System typically consists of several key components, each playing a crucial role in the assembly process. Below is a detailed breakdown of these components:

3.1 Wax Pattern Feeding Mechanism

The Wax Pattern Feeding Mechanism is responsible for delivering individual wax patterns to the assembly station. This mechanism typically includes:

- Fixed Frame: A sturdy frame that holds the wax patterns in place.

- Trays: Trays that hold the wax patterns and can be easily loaded and unloaded.

- Positioning Pins: Pins that ensure the trays are correctly aligned for the robotic arm to pick up the wax patterns.

3.2 Conveyor and Rotating Mechanism

The Conveyor and Rotating Mechanism moves the wax patterns and the central sprue to the correct positions for assembly. This mechanism includes:

- Servo Motors: These motors provide precise control over the movement of the conveyor and rotating table.

- Lead Screws: Lead screws convert the rotational motion of the servo motors into linear motion, allowing for precise positioning.

- Rotating Table: A table that rotates the central sprue, allowing wax patterns to be attached at various angles.

3.3 Gripping Mechanism

The Gripping Mechanism is responsible for picking up the wax patterns and placing them onto the central sprue. This mechanism includes:

- Robotic Arm: A six-axis robotic arm that provides flexibility and precision in handling the wax patterns.

- Quick-Change Tooling: A system that allows for easy switching between different gripping tools, depending on the size and shape of the wax patterns.

- Pneumatic Grippers: Grippers that use compressed air to securely hold the wax patterns during assembly.

3.4 Welding Mechanism

The Welding Mechanism is used to attach the wax patterns to the central sprue. This mechanism includes:

- Heating Tool: A tool that heats the wax patterns and the sprue to create a strong bond.

- Preheating Plate: A plate that preheats the wax patterns before they are attached to the sprue, ensuring a consistent weld.

- Wax Removal Tool: A tool that removes any excess wax from the heating tool, ensuring clean and precise welds.

3.5 Control System

The Control System is the brain of the automatic wax pattern assembly system. It coordinates the movements of the robotic arm, conveyor, and welding mechanism, ensuring that the entire process runs smoothly. The control system includes:

- Programmable Logic Controller (PLC): A PLC that processes input signals and controls the output devices.

- Human-Machine Interface (HMI): An interface that allows operators to monitor and control the system.

- Safety Features: Safety features such as emergency stop buttons, safety relays, and warning lights to ensure safe operation.

4. Software and Communication

The software and communication systems are critical to the operation of the automatic wax pattern assembly system. These systems ensure that all components work together seamlessly.

4.1 Controller Software

The Controller Software is responsible for managing the entire assembly process. It includes:

- Data Processing: The software processes data from sensors and other input devices to make real-time decisions.

- Communication: The software communicates with the robotic arm, servo motors, and other components to coordinate their movements.

- User Interface: The software provides a user-friendly interface for operators to monitor and control the system.

4.2 Robotic Arm Communication

The Robotic Arm Communication system ensures that the robotic arm can communicate with the controller. This system includes:

- Profinet Interface: A communication interface that allows the robotic arm to connect to the controller.

- Network Configuration: The network must be configured with the correct IP addresses and subnet masks to ensure proper communication.

- Real-Time Communication: The system must support real-time communication to ensure that the robotic arm can respond quickly to commands from the controller.

5. Benefits of Automatic Wax Pattern Assembly Systems

The adoption of automatic wax pattern assembly systems offers several significant benefits:

5.1 Improved Consistency and Quality

Automated systems ensure that each wax pattern is attached to the central sprue with the same precision and consistency. This leads to higher-quality castings with fewer defects.

5.2 Increased Efficiency

Automated systems can operate continuously without the need for breaks, leading to increased production efficiency. Additionally, the systems can handle higher volumes of production, making them ideal for large-scale manufacturing.

5.3 Reduced Labor Costs

By automating the wax pattern assembly process, manufacturers can reduce their reliance on skilled labor, leading to significant cost savings.

5.4 Enhanced Safety

Automated systems reduce the need for manual handling of hot wax and other hazardous materials, leading to a safer working environment.

5.5 Scalability

Automatic wax pattern assembly systems can be easily scaled up or down to meet changing production demands, making them highly versatile.

6. Case Study: Application in Aerospace Manufacturing

To illustrate the benefits of automatic wax pattern assembly systems, let’s consider a case study in the aerospace industry.

6.1 Background

A leading aerospace manufacturer was facing challenges in producing complex titanium components using traditional investment casting methods. The manual assembly of wax patterns was leading to inconsistencies in the final castings, resulting in high rejection rates and increased production costs.

6.2 Implementation of Automatic System

The manufacturer decided to implement an automatic wax pattern assembly system to address these challenges. The system included a six-axis robotic arm, a precision welding mechanism, and an advanced control system.

6.3 Results

After implementing the automatic system, the manufacturer observed the following results:

- Reduced Rejection Rates: The consistency of the wax pattern assembly led to a significant reduction in casting defects, resulting in lower rejection rates.

- Increased Production Efficiency: The automated system allowed the manufacturer to increase production volumes without compromising on quality.

- Cost Savings: The reduction in labor costs and material waste led to significant cost savings.

7. Future Trends and Developments

The future of automatic wax pattern assembly systems looks promising, with several trends and developments on the horizon:

7.1 Integration with Industry 4.0

As the manufacturing industry moves towards Industry 4.0, automatic wax pattern assembly systems are expected to become more integrated with other smart manufacturing technologies. This integration will enable real-time monitoring, predictive maintenance, and advanced data analytics.

7.2 Advancements in Robotics

Advancements in robotics, such as collaborative robots (cobots), are expected to further enhance the capabilities of automatic wax pattern assembly systems. These robots can work alongside human operators, providing greater flexibility and efficiency.

7.3 Improved Materials and Processes

Research into new materials and processes, such as 3D printing of wax patterns, is expected to further improve the efficiency and precision of investment casting.

8. Conclusion

The development and application of Automatic Wax Pattern Assembly Systems represent a significant advancement in the investment casting industry. These systems offer numerous benefits, including improved consistency, increased efficiency, reduced labor costs, and enhanced safety. As the industry continues to evolve, the integration of these systems with other smart manufacturing technologies will further enhance their capabilities, making them an essential tool for manufacturers seeking to stay competitive in a rapidly changing market.

Tables

Table 1: Comparison of Manual vs. Automatic Wax Pattern Assembly

| Aspect | Manual Assembly | Automatic Assembly |

|---|---|---|

| Consistency | Low | High |

| Efficiency | Low | High |

| Labor Costs | High | Low |

| Quality Control | Prone to human error | Consistent and reliable |

| Scalability | Limited | Highly scalable |

Table 2: Key Components of an Automatic Wax Pattern Assembly System

| Component | Function |

|---|---|

| Wax Pattern Feeding | Delivers individual wax patterns to the assembly station. |

| Conveyor and Rotating | Moves wax patterns and sprue to correct positions for assembly. |

| Gripping Mechanism | Picks up and places wax patterns onto the central sprue. |

| Welding Mechanism | Attaches wax patterns to the central sprue using heat. |

| Control System | Coordinates the movements of all components and ensures smooth operation. |

Table 3: Benefits of Automatic Wax Pattern Assembly Systems

| Benefit | Description |

|---|---|

| Improved Consistency | Ensures each wax pattern is attached with the same precision and consistency. |

| Increased Efficiency | Operates continuously, leading to higher production volumes. |

| Reduced Labor Costs | Reduces reliance on skilled labor, leading to cost savings. |

| Enhanced Safety | Reduces manual handling of hazardous materials, improving safety. |

| Scalability | Easily scaled up or down to meet changing production demands. |