Introduction

In the competitive landscape of the new energy vehicle market, the focus has shifted towards extending the driving range and enhancing energy efficiency. Automakers are increasingly adopting lightweight materials such as aluminum alloys to replace traditional steel components, thereby improving the vehicle’s range and environmental performance. The demand for lightweight solutions has led to the exploration of advanced manufacturing processes that offer high strength and precision while reducing material consumption and costs.

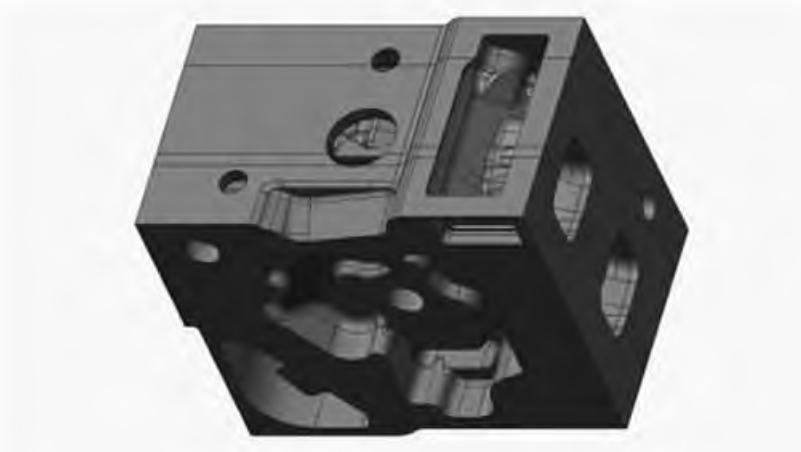

This article delves into the design and development of an extrusion casting process for an aluminum alloy suspension bracket arm, a critical component in vehicles. The study focuses on optimizing the casting system, improving cooling conditions, and evaluating the impact of different T6 heat treatment processes on the microstructure and mechanical properties of the castings.

Product Information and Extrusion Casting Process Analysis

The suspension bracket arm, originally produced using ZL111 gravity casting, was transitioned to A356.2 extrusion casting to enhance durability and reduce costs. The casting weighs 1.0556 kg, with a wall thickness of 4.5 mm and overall dimensions of 264 mm × 129 mm × 113 mm. The mechanical properties required for the casting include a tensile strength of ≥ 310 MPa, yield strength of ≥ 245 MPa, and elongation of ≥ 8%. The transition to extrusion casting resulted in a 5% reduction in weight.

Casting System Design and Improvement

The casting system was designed to ensure proper cooling channel arrangement and optimal use of the extrusion casting machine’s clamping force. The initial design included a single-cavity mold with a gating system comprising a runner, gates, vents, and overflow wells. Simulation analysis using AnyCasting software revealed potential shrinkage defects in specific areas, prompting design modifications.

Initial Design and Simulation

The initial gating system design was subjected to filling and solidification simulations. The filling simulation indicated a filling speed of 0.40-0.60 m/s at the gate, with no significant air entrapment. However, the solidification simulation identified isolated liquid phases in certain areas, indicating a high risk of shrinkage defects.

Optimization and Results

To address the identified issues, the gating system was optimized by adding an additional gate in the problematic area. The modified design was re-simulated, showing improved filling and solidification patterns. The temperature field simulation confirmed sequential solidification, with the gate area solidifying last. The optimized design significantly reduced shrinkage defects, with most defects confined to the overflow wells and vents.

Heat Treatment Process

The aluminum castings underwent T6 heat treatment to refine the grain structure and enhance mechanical properties. Four different heat treatment schemes were tested:

- Scheme 1: 525°C for 4 hours (solution treatment) + 155°C for 4 hours (aging) + water quenching.

- Scheme 2: 525°C for 4 hours + 165°C for 5 hours + water quenching.

- Scheme 3: 525°C for 6 hours + 155°C for 4 hours + water quenching.

- Scheme 4: 525°C for 6 hours + 165°C for 5 hours + water quenching.

Mechanical Properties and Microstructure Analysis

The mechanical properties of the castings were evaluated after each heat treatment scheme. Scheme 3 yielded the best results, with an average tensile strength of 340.5 MPa, yield strength of 274.5 MPa, and elongation of 10%. The microstructure analysis revealed that the solution treatment time and aging temperature significantly influenced the mechanical properties. Prolonged solution treatment and higher aging temperatures led to coarsening of the silicon particles, reducing elongation.

Conclusion

The study demonstrated that extrusion casting, combined with an optimized gating system and appropriate heat treatment, can produce aluminum alloy suspension bracket arms with excellent mechanical properties and reduced defects. The sequential solidification achieved through the optimized gating system, along with localized pressurization and cooling, effectively eliminated shrinkage defects. The recommended heat treatment scheme (525°C for 6 hours + 155°C for 4 hours + water quenching) significantly improved the elongation of the castings.

Tables and Figures

Table 1: T6 Heat Treatment Results

| Scheme | Sample ID | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1 | 1-1 | 314 | 245 | 8.3 |

| 1-2 | 298 | 241 | 5.8 | |

| 2 | 2-1 | 331 | 263 | 7 |

| 2-2 | 291 | 262 | 3.9 | |

| 3 | 3-1 | 339 | 275 | 9.4 |

| 3-2 | 340 | 272 | 10.3 | |

| 4 | 4-1 | 331 | 275 | 6.5 |

| 4-2 | 295 | 262 | 3.6 |