Introduction

Wind energy has emerged as a pivotal component in the global shift towards renewable energy sources. The efficiency and reliability of wind turbines are critical to harnessing this energy effectively. Among the various components of a wind turbine, the suspension beam plays a crucial role in supporting the generator and other mechanical parts. Traditionally, low-grade ductile iron has been used for wind power castings. However, with the increasing demand for higher performance and durability, there is a growing need for materials with superior mechanical properties, such as high elongation and strength.

This article delves into the casting process design and simulation of a wind turbine suspension beam using QT500-14 ductile iron. The study employs MAGMA simulation software to optimize the casting process, ensuring the final product meets stringent technical requirements. The article also explores the impact of key elements like carbon (C), silicon (Si), and manganese (Mn) on the microstructure and mechanical properties of the castings.

1. Casting Process Design and Optimization

1.1 Structural Analysis of the Wind Turbine Suspension Beam

The wind turbine suspension beam is a complex component with significant variations in wall thickness. The maximum external dimensions of the casting are 670 mm × 250 mm × 250 mm, with a mass of 138 kg. The material used is QT500-14, a ductile iron with specific chemical composition requirements, as shown in Table 1.

Table 1: Chemical Composition of QT500-14 (mass fraction/%)

| Element | C | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|---|

| Content | 3.0-3.5 | 3.7-4.3 | ≤0.50 | ≤0.025 | ≤0.05 | Bal. |

The casting must be free from defects such as shrinkage porosity, gas holes, and sand inclusions, which are common in thick-walled castings.

1.2 Initial Casting Process Design

The initial casting process design involves the use of resin sand molds, with one mold per casting. A sand core is designed for the middle hole of the casting, where it is impossible to remove the pattern. Filters are placed on both sides of the sprue to prevent slag inclusion and turbulence. The gating system is placed on one side of the casting, with four ingates designed to ensure smooth filling and avoid defects like cold shuts and sand holes.

The riser design is based on the modulus method, with the riser modulus set at 1.2 times the casting modulus. The riser is placed at the top of the casting to ensure both internal and external quality.

Figure 1: Schematic Diagram of the Casting Dimensions

1.3 Simulation Analysis and Process Optimization

To validate the reliability of the casting process, MAGMA simulation software is used to simulate the solidification process of the suspension beam. The casting, riser, and gating system are converted into STL format and imported into the MAGMA simulation system. The mesh is optimized to form 2,099,766 nodes and 472,057 elements. The chemical composition is controlled according to Table 1.

Table 2: Simulation Parameters

| Parameter | Value |

|---|---|

| Casting material | QT500-14 |

| Mold material | Resin sand |

| Initial pouring temperature | 1340°C |

| Pouring time | 15s |

1.3.1 Preliminary Simulation Results

The preliminary simulation results indicate that the riser’s feeding capacity is insufficient, as the casting is not fully solidified when the iron reaches 99.5% solidification. Shrinkage porosity and hot spots are observed in the casting, suggesting a high risk of defects.

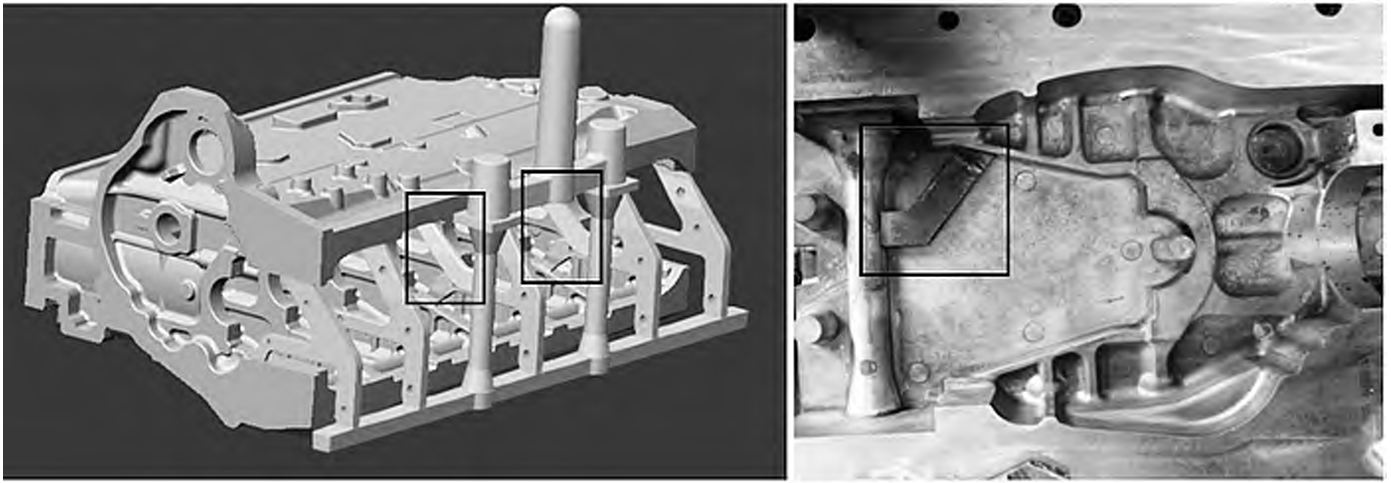

Figure 2: Simulation Results

1.3.2 Process Optimization

To address the issues identified in the preliminary simulation, chills are added to the thick sections of the casting to enhance the riser’s feeding distance. The chills are designed based on the formula:δ=GρAδ=ρAG

where GG is the mass of the chill, ρρ is the density of the chill, and AA is the contact area of the chill.

Figure 3: Process Scheme with the Addition of Chills

The optimized simulation results show that the casting is free from independent liquid phases, and the hot spots are confined to the riser, indicating that the casting is free from shrinkage porosity and shrinkage holes.

2. Experimental Materials and Methods

The experimental materials include 10% pig iron, 60% return scrap, and 30% steel scrap. The materials are dried and melted in a 1-ton ABP medium-frequency induction furnace. The molten iron is heated to 1500-1530°C and held for 5-10 minutes before slag removal. The spheroidizing agent used is Elmag5932, and the inoculant is a silicon-barium inoculant added at 0.6%. The pouring temperature is maintained at 1340±10°C, and the casting is cooled for 10 hours before shakeout.

3. Results and Discussion

3.1 Analysis of Shrinkage Porosity Defects

The optimized casting process is used to produce the suspension beam. The casting is sectioned at 10 mm intervals and inspected using PT (Penetrant Testing). The results show no red indications, indicating that the internal structure of the casting is dense and free from shrinkage porosity and shrinkage holes.

3.2 Microstructure and Mechanical Properties

The microstructure of the QT500-14 suspension beam is examined using a Leica DM18 C optical microscope. The graphite nodularity is greater than 90%, and the pearlite content is 1%, meeting the technical requirements.

Table 3: Mechanical Properties and Microstructure of the Suspension Beam

| Tensile Test Bar | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Nodularity (%) | Area Fraction of Pearlite (%) |

|---|---|---|---|---|---|---|

| 1 | 526 | 415 | 18.5 | 185-194 | 90 | 1 |

| 2 | 555 | 456 | 14 | 189 (average) | ≥80 | ≤5 |

| Technical Criteria | ≥480 | ≥390 | ≥12 | 170-200 | ≥80 | ≤5 |

4. Conclusion

- Simulation Results: The simulation results demonstrate that with a well-designed gating and riser system, combined with the use of chills, shrinkage porosity and shrinkage holes can be eliminated, resulting in a high-quality casting.

- Optimized Process: The optimized casting process produces a suspension beam with a tensile strength greater than 526 MPa, yield strength greater than 415 MPa, elongation greater than 14%, and an average hardness of 189 HB. The nodularity is greater than 90%, and the pearlite content is 1%, meeting the technical requirements for mechanical properties and microstructure.

- Defect-Free Casting: The actual production of the suspension beam using the optimized process results in a casting free from internal defects, as confirmed by sectioning and PT inspection.