1. Introduction

As a senior engineer specializing in mining equipment manufacturing, I have dedicated years to optimizing the durability and performance of critical components in mineral processing systems. Among these, lining plates for large semi-autogenous grinding (SAG) mills stand out due to their pivotal role in maintaining operational efficiency. This article delves into the comprehensive optimization of lining plate design, material selection, casting processes, and heat treatment parameters, with a focus on achieving a service life exceeding 120 days.

2. Challenges in Lining Plate Performance

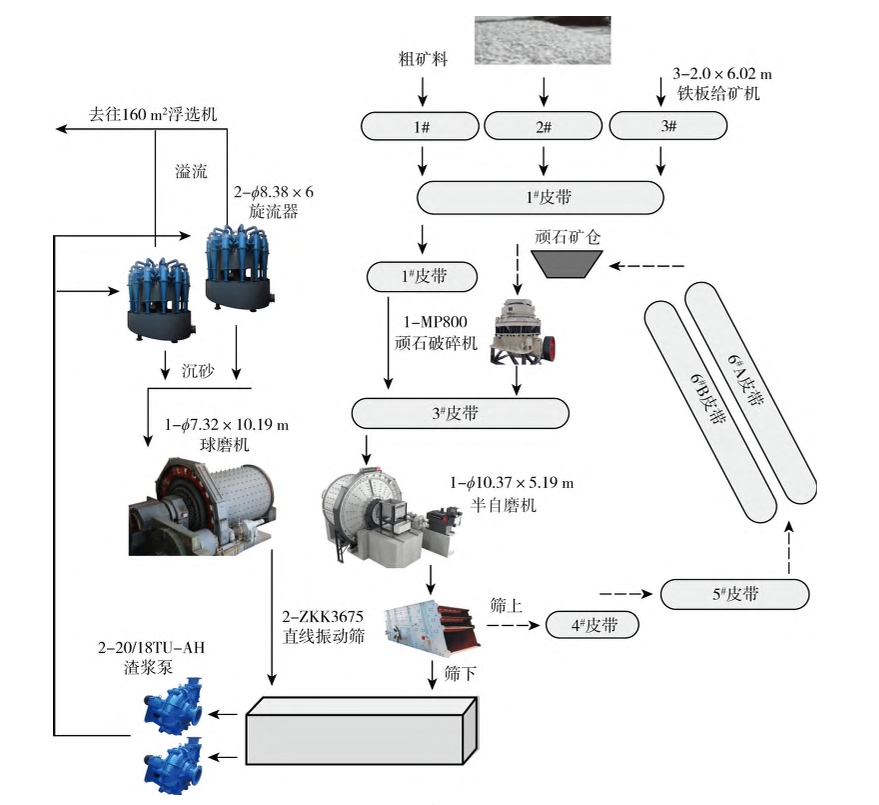

The primary challenge for lining plates in large SAG mills (e.g., Φ10.37 m × 5.19 m) lies in their exposure to extreme mechanical stress. During operation, ore particles exceeding 250 mm in size and grinding media (≥120 mm diameter) generate high-impact forces, leading to premature failure modes such as cracking and accelerated wear. Initial designs of lining plates exhibited an average lifespan of only 20–30 days, necessitating urgent improvements.

3. Structural Optimization of Lining Plates

3.1 Initial Design Limitations

The original lining plate configuration featured two rows of 44 plates each (total 88 plates), with dimensions up to 350 mm in length and weights exceeding 2,000 kg. This design suffered from:

- Excessive width-to-thickness ratios, causing stress concentration.

- Insufficient resistance to bending under cyclic loading.

3.2 Discrete Element Method (DEM) Simulation

Using EDEM software, we simulated ore and grinding media trajectories to analyze stress distribution and energy transfer. Key parameters optimized included:

- Mill rotation speed

- Lining plate height and face angle

- Arrangement patterns

3.3 Revised Design

Based on simulation results, the lining plate structure was redesigned:

- Three-row arrangement: 66 plates per row (198 total).

- Alternating high-low profiles: Improved energy absorption.

- Reduced length and width to minimize stress.

| Parameter | Initial Design | Optimized Design |

|---|---|---|

| Number of rows | 2 | 3 |

| Plates per row | 44 | 66 |

| Plate length (mm) | 350 | 280 |

| Weight per plate (kg) | 2,000 | 1,600 |

4. Material Selection and Composition

4.1 Limitations of Traditional Materials

- High-manganese steel: High toughness but low yield strength, leading to deformation.

- Pearlitic Cr-Mo steel: Adequate hardness but prone to fracture under high carbon content (0.6–0.85%).

4.2 Optimized Alloy Design

The final composition for lining plates balanced hardness, toughness, and淬透性 (hardenability):

| Element | Composition (%) | Role |

|---|---|---|

| C | 0.5–0.7 | Strength and wear resistance |

| Cr | 2.0–3.5 | Corrosion resistance, hardenability |

| Mo | 0.3–0.5 | Grain refinement |

| Ni | 0.2–0.4 | Toughness enhancement |

| Cu | 0.1–0.3 | Oxidation resistance |

The hardness-toughness balance was validated using the following empirical formula for wear resistance:W=k⋅H1.5⋅T0.5W=k⋅H1.5⋅T0.5

Where WW = wear resistance, HH = hardness (HRC), TT = toughness (J/cm²), and kk = material constant.

5. Casting Process Improvements

5.1 Initial Casting Defects

Early lining plates exhibited cracks near gating systems due to:

- Non-uniform cooling rates.

- Residual stresses from improper feeding.

5.2 Optimized Gating Design

The revised process included:

- Centralized circular sprue (ceramic tube).

- Single-channel feeding for sequential solidification.

- Delayed shakeout (<300°C surface temperature).

6. Heat Treatment Protocol

To achieve a tempered martensite microstructure, a three-stage heat treatment was implemented:

| Stage | Temperature (°C) | Duration (h) | Objective |

|---|---|---|---|

| Annealing | 880–900 | 4–6 | Stress relief, homogenization |

| Quenching | 850–870 | 2–3 | Martensite formation |

| Tempering | 550–600 | 4–5 | Toughness enhancement |

Resultant mechanical properties met operational demands:

| Property | Target | Achieved |

|---|---|---|

| Hardness (HRC) | >35 | 35–42 |

| Impact toughness (J/cm²) | >40 | 60–80 |

| Tensile strength (MPa) | — | 950–1,100 |

7. Field Performance and Wear Analysis

Post-optimization lining plates achieved an average lifespan of 125 days in Φ10.37 m × 5.19 m SAG mills. Wear rate analysis (Table 1) revealed:

| Plate Type | Initial Weight (kg) | Residual Weight (kg) | Wear Rate (%) |

|---|---|---|---|

| High-profile | 815–1,410 | 390–770 | 40–55 |

| Low-profile | 450–780 | 240–460 | 41–50 |

| Total | 4,791 | 2,600 | 46 |

8. Conclusion

Through iterative design enhancements, material science innovations, and process refinements, the service life of lining plates in large SAG mills was extended to over 120 days. Key takeaways include:

- DEM-guided structural optimization minimizes stress concentrations.

- Balanced alloy composition (Cr-Mo-Ni-Cu) ensures hardness-toughness synergy.

- Centralized gating and staged heat treatment eliminate casting defects.

This holistic approach provides a blueprint for advancing lining plate technology in heavy-duty grinding applications.