Introduction

In the manufacturing of large engine cylinder blocks, the removal of core sand is a critical step that significantly impacts the quality and efficiency of production. Traditional methods such as manual knocking and sand bed vibration have limitations in terms of labor intensity, production efficiency, and the risk of damaging the engine cylinder block. To address these challenges, our company has introduced vibratory decoring equipment, which utilizes mechanical vibration principles to efficiently remove core sand while minimizing the risk of damage to the engine cylinder block.

Design Philosophy

Flexible Design Concept

Given the variety of large-bore engines produced in our factory, we adopted the concept of Flexible Manufacturing Systems (FMS). This approach allows the vibratory decoring equipment to handle multiple types of engine cylinder blocks. Specifically, the equipment is designed to accommodate both V-type and inline engine configurations, utilizing two sets of six vibrators. This flexibility ensures that the machine can be used for a wide range of engine cylinder blocks, enhancing its utility and efficiency.

Lean Production Concept

We applied the ECRS (Eliminate, Combine, Rearrange, Simplify) principle to streamline the production process. The entire workflow, including loading and unloading, vibratory decoring, vibration sand removal, and waste sand recycling, is integrated into a single production line. This integration maximizes the removal of sand from the engine cylinder block and ensures efficient recycling of waste sand, thereby improving overall production efficiency.

Environmental Concept

To ensure a safe and environmentally friendly production process, the equipment is equipped with soundproofing covers, vibration isolation devices, and dust removal systems. These features minimize noise and dust emissions, ensuring compliance with safety and environmental standards.

Equipment Structure and Working Process

Equipment Structure

The vibratory decoring machine consists of several key components, including loading and unloading roller conveyors, vibratory mechanisms, flipping mechanisms, and soundproofing and dust removal covers.

Working Process

The working process of the vibratory decoring machine is as follows:

- Loading: The engine cylinder block is manually placed on the loading roller conveyor.

- Positioning: The block is transported to the vibratory worktable, where it is positioned and secured.

- Vibratory Decoring: The vibrators apply high-energy vibrations to the engine cylinder block, causing the core sand to detach from the block.

- Vibration Sand Removal: The block is then transferred to the vibration mechanism, where residual sand is removed.

- Waste Sand Recycling: The removed sand is collected and transported to a sand recycling system.

- Unloading: The cleaned engine cylinder block is returned to the loading point via the unloading roller conveyor.

This cycle is repeated continuously to achieve efficient decoring of engine cylinder blocks.

Process Parameter Optimization

Tooling Design

The tooling is designed to support the engine cylinder block during the decoring process. The positioning points are based on the tile mouth of the block, and custom tooling is designed for different types of engine cylinder blocks.

Determination of Vibratory Positions

To avoid damage to critical areas such as the cylinder bore, the vibratory positions are carefully selected. The vibratory positions for both V-type and inline engine cylinder blocks .

Parameter Setting

The key factors affecting the decoring process are the vibratory time and the vibration time. To scientifically determine the optimal parameters, we conducted a 2K full factorial experiment. The experimental design and results are summarized in Table 1.

Table 1: 2K Full Factorial Experiment Design

| Standard Order | Run Order | Center Point | Block | Vibratory Time (s) | Vibration Time (s) | Experimental Result (kg) |

|---|---|---|---|---|---|---|

| 1 | 7 | 1 | 1 | 5 | 10 | 15.5 |

| 2 | 3 | 1 | 1 | 20 | 10 | 18.6 |

| 3 | 5 | 1 | 1 | 5 | 60 | 28.6 |

| 4 | 6 | 1 | 1 | 20 | 60 | 45.3 |

| 5 | 1 | 0 | 1 | 12.5 | 35 | 42.2 |

| 6 | 2 | 0 | 1 | 12.5 | 35 | 43.5 |

| 7 | 4 | 0 | 1 | 12.5 | 35 | 40.3 |

The results of the experiment were analyzed using response surface methodology (RSM). The regression equation derived from the RSM analysis is as follows:

Sand Removal Amount=7.48+1.06×Vibration Time+3.05×Vibratory Time−0.012×Vibration Time×Vibratory Time−0.12×Vibratory Time2+0.018×Vibration Time×Vibratory TimeSand Removal Amount=7.48+1.06×Vibration Time+3.05×Vibratory Time−0.012×Vibration Time×Vibratory Time−0.12×Vibratory Time2+0.018×Vibration Time×Vibratory Time

The analysis revealed that the optimal vibratory time is 13 seconds, and the optimal vibration time is 45 seconds. These parameters ensure maximum sand removal without causing damage to the engine cylinder block.

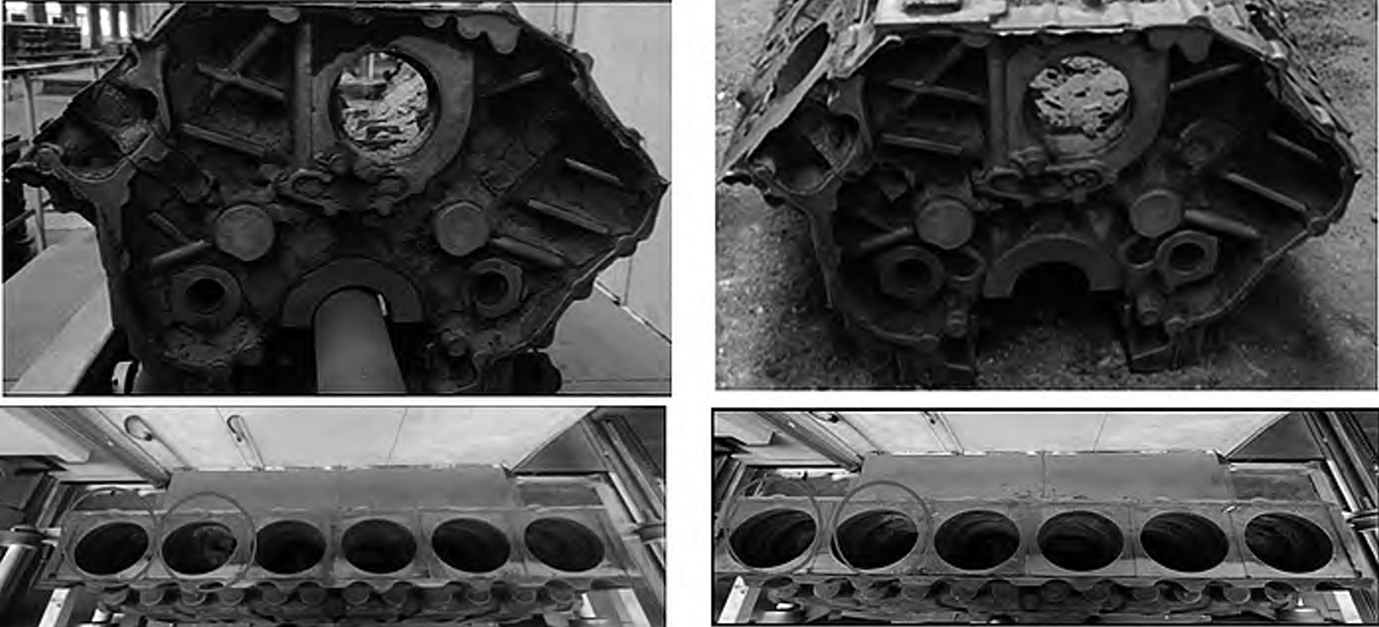

Effect Confirmation

The effectiveness of the vibratory decoring process was confirmed by comparing the engine cylinder blocks before and after the process. Before decoring, the blocks had a layer of sand adhered to the surface, and large sand blocks were present in the cylinder bores. After decoring, the surface sand was significantly removed, and no large sand blocks remained in the cylinder bores.

Conclusion

- Flexible and Efficient Design: The vibratory decoring equipment was designed with flexibility, efficiency, and environmental considerations in mind, ensuring high-quality production of engine cylinder blocks.

- Optimal Parameter Determination: Through 2K full factorial experiments and response surface methodology, the optimal vibratory and vibration times were determined to be 13 seconds and 45 seconds, respectively.

- Effective Sand Removal: The vibratory decoring process effectively removes sand from the surface and internal cavities of the engine cylinder block, significantly improving the quality of the final product.