Abstract

In industries such as mineral processing, chemicals, and ceramics, the semi-autogenous grinding (SAG) mill–ball mill process is widely adopted for raw material grinding. Under the premise of meeting production demands and reducing energy consumption, the service life of wear-resistant components, particularly the lining plates of ball mills, significantly impacts equipment availability. Through comparative studies under near-identical operating conditions, this paper evaluates the performance of manganese steel lining plates, monolithic composite lining plates, and split-type composite lining plates. The results demonstrate that split-type lining plates exhibit superior durability, cost-effectiveness, and operational efficiency.

Keywords: Ball mill; Lining plate selection; Cost reduction and efficiency improvement

1. Introduction

In a zinc-tin ore processing plant in Yunnan, China, three production systems (A, B, and C) were established. System A and B utilized Φ2700×3600 primary ball mills and Φ2400×3000 secondary ball mills, while System C employed a Φ4500×2400 SAG mill paired with a Φ3200×4000 ball mill. Frequent issues arose in the Φ2700×3600 ball mills, including short lifespans of lining plates, difficulties in adjusting wear-resistant structures, prolonged replacement cycles, and localized wear. These problems led to low operational stability, increased maintenance complexity, and irregular planned downtime.

2. Challenges with Manganese Steel Lining Plates

The plant initially used manganese steel lining plates, which posed several critical limitations:

2.1 Short Lifespan, Heavy Weight, and Replacement Difficulties

- Service Life: 8–9 months (2014–2018 data).

- Weight: Total weight of 23.48 tons, with individual plates exceeding 100 kg (up to 200 kg).

- Replacement Time: 5–6 days per cycle, requiring heavy machinery and posing safety risks.

2.2 Excessive Noise

Noise levels averaged 92.38 dB(A) (Table 1), exceeding the occupational exposure limit of 85 dB(A).

Table 1: Noise Levels with Manganese Steel Lining Plates (2018)

| Month | Jan | Feb | Mar | Apr | May | Jun |

|---|---|---|---|---|---|---|

| dB(A) | 91.2 | 92.3 | 94.3 | 96.2 | 94.9 | 92.4 |

| Month | Jul | Aug | Sep | Oct | Nov | Dec |

| dB(A) | 89.6 | 87.4 | 89.8 | 89.2 | 87.8 | 88.5 |

2.3 Unstable Performance

Manganese steel plates exhibited poor impact resistance, leading to frequent cracking and unpredictable wear patterns.

2.4 Poor Sealing

Rapid wear caused bolt loosening and slurry leakage, necessitating unscheduled shutdowns for bolt tightening.

3. Transition to Rubber Composite Lining Plates

In 2018, rubber composite lining plates were introduced to address the shortcomings of manganese steel.

3.1 Advantages

- Weight Reduction: Total weight decreased to 15.05 tons, with individual plates averaging 70 kg.

- Installation Efficiency: Replacement time reduced from 6 days to 4 days.

- Noise Reduction: Average noise levels dropped to 88.28 dB(A) (Table 2).

Table 2: Noise Levels with Rubber Composite Lining Plates (2018)

| Month | Jan | Feb | Mar | Apr | May | Jun |

|---|---|---|---|---|---|---|

| dB(A) | 88.1 | 89.3 | 88.1 | 87.1 | 89.1 | 87.7 |

| Month | Jul | Aug | Sep | Oct | Nov | Dec |

| dB(A) | 89.6 | 87.4 | 89.8 | 89.2 | 87.8 | 88.5 |

- Improved Sealing: Elasticity of rubber minimized bolt loosening, reducing annual downtime by 40 hours.

3.2 Limitations

- Short Lifespan at Feed/Discharge Ends: Wave-structured rubber plates lasted only 3–6 months due to accelerated wear.

- Unpredictable Maintenance: Irregular replacement cycles increased safety risks in confined spaces.

4. Breakthrough: Split-Type Composite Lining Plates

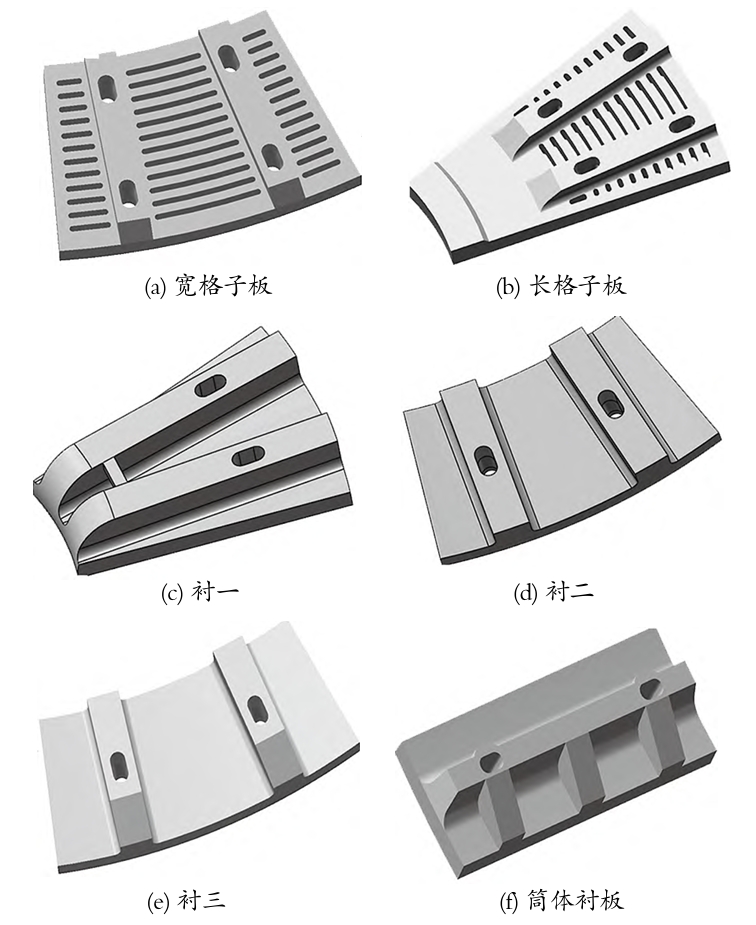

In 2021, split-type composite lining plates were introduced, featuring a separable design with lifters and base plates.

4.1 Performance Improvements

- Weight Reduction:

- Lifter weight reduced by 30–69%.

- Base plate weight reduced by 47–53%.

- Extended Service Life:

- Feed/discharge end lifespan increased from 3 months to >10 months.

- Annual replacement frequency reduced from 4 to 1.

- Energy Efficiency:

- Power consumption lowered by 30 kW compared to wave-structured plates.

4.2 Economic Benefits

- Reduced Replacement Costs: Only lifters required replacement, saving CNY 70,000 annually.

- Downtime Reduction: Maintenance time decreased from 4 days to 3 days.

Table 3: Cost Comparison of Lining Plate Types

| Parameter | Manganese Steel | Rubber Composite | Split-Type Composite |

|---|---|---|---|

| Weight (tons) | 23.48 | 15.05 | 8.92 |

| Lifespan (months) | 8–9 | 3–6 | >10 |

| Noise Level (dB(A)) | 92.38 | 88.28 | 85.50 |

| Annual Cost (CNY) | 120,000 | 90,000 | 50,000 |

5. Technical Analysis and Formulas

5.1 Wear Rate Calculation

The wear rate (WW) of lining plates can be modeled as:W=ΔmA⋅tW=A⋅tΔm

Where:

- ΔmΔm = Mass loss (kg)

- AA = Surface area (m²)

- tt = Operating time (hours)

5.2 Energy Savings

Power savings (PsavedPsaved) for split-type plates:Psaved=Pwave−Psplit=30 kWPsaved=Pwave−Psplit=30kW

6. Conclusion

The adoption of split-type composite lining plates in small ball mills resolves critical challenges associated with traditional materials. Key achievements include:

- Enhanced durability and reduced maintenance frequency.

- Significant noise reduction and improved workplace safety.

- Annual cost savings exceeding CNY 70,000.

This innovation aligns with industrial demands for sustainability, efficiency, and worker well-being, setting a benchmark for future advancements in ball mill technology.