Abstract

The challenge of protective coatings on engine cylinder block being easily damaged and peeled off during ultrasonic-chemical cleaning processes. A high-performance waterborne one-component dip-coating was developed to enhance adhesion, water resistance, salt spray resistance, and ultrasonic-chemical cleaning resistance. Key components such as film-forming resins, wetting agents, driers, and adhesion promoters were systematically optimized. The results demonstrate that a blend of waterborne acrylic-modified epoxy ester resin (TH-8180) and modified waterborne epoxy dispersion (H-502-42W) at a mass ratio of 6:4, combined with a synergistic wetting agent system (BW-104E:HOS 2413 = 2:3), 5% cobalt-free drier (OXY-Coat1101), and 1.5% adhesion promoter (MOAP 1880), achieves superior performance. The optimized coating exhibits excellent wettability, rapid drying, and robust resistance to harsh cleaning conditions, making it ideal for engine cylinder block protection.

1. Introduction

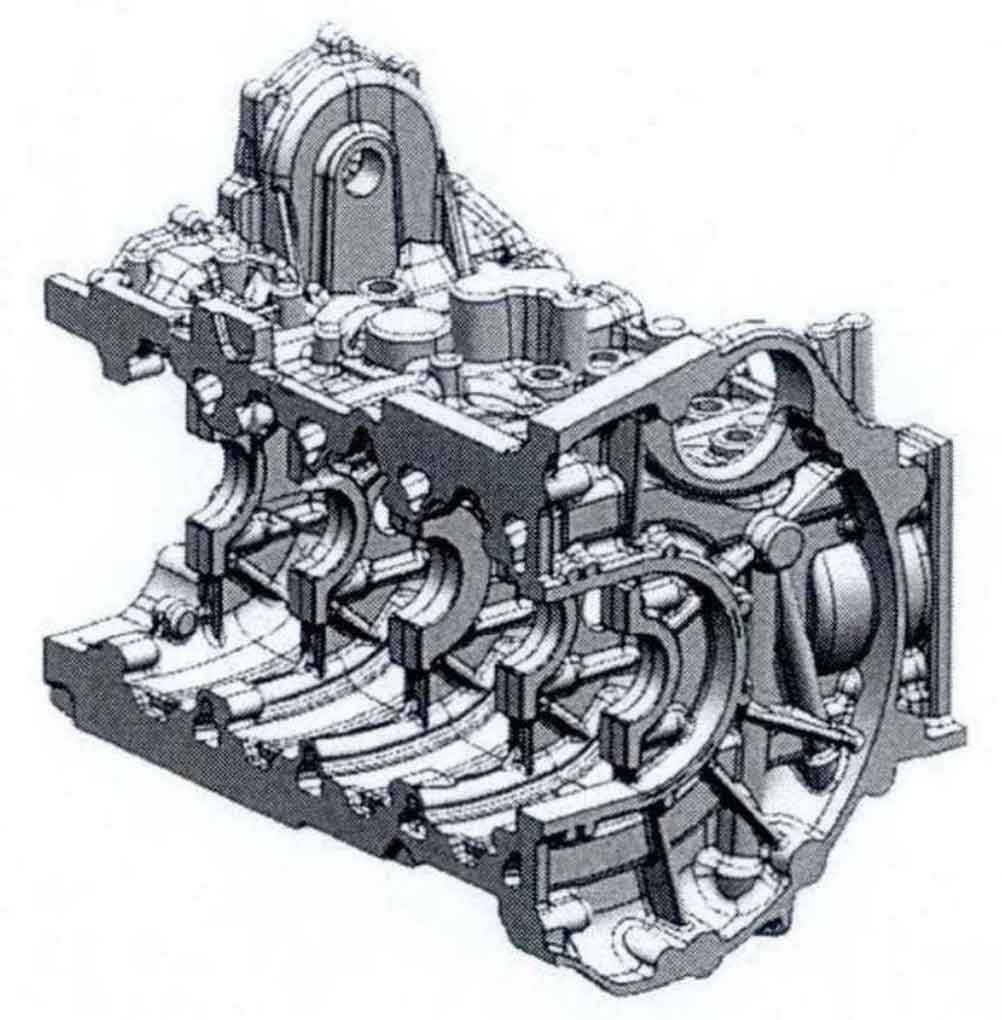

Engine cylinder block, typically made of cast iron, require robust protective coatings to withstand manufacturing processes such as ultrasonic-chemical cleaning. Traditional coatings often fail due to solvent penetration and cavitation-induced delamination. This study aims to develop a waterborne one-component dip-coating that combines low-temperature curing, fast drying, and exceptional durability. By focusing on resin compatibility, surface wetting, and crosslinking efficiency, we address the limitations of existing solutions for engine cylinder block applications.

2. Experimental Design

2.1 Materials and Instruments

Key raw materials included:

- Resins: TH-8180 (acrylic-modified epoxy ester), H-502-42W (modified epoxy dispersion).

- Wetting agents: BW-104E (alkynediol-based), HOS 2413 (siloxane-based).

- Driers: OXY-Coat1101 (cobalt-free), Octa-Soligen421 aqua.

- Adhesion promoters: MOAP 1880 (silane coupling agent).

Instruments: Adhesion tester (QFZ-II), salt spray chamber (SH series), ultrasonic cleaner (BJCS1700), and contact angle analyzer (KJ-625).

2.2 Coating Formulation

The coating was prepared using the formulation outlined in Table 1.

Table 1. Formulation of waterborne one-component dip-coating

| Component | Weight (%) |

|---|---|

| Deionized water | 5–10 |

| Amine neutralizer | 0.3–1.0 |

| Dispersant | 2–3 |

| Defoamer | 0.1–1.0 |

| Bentonite | 0.2–0.5 |

| Carbon black | 1.0–3.0 |

| Anticorrosive pigment | 4–8 |

| Talc | 3–5 |

| Barium sulfate | 15–30 |

| Resin blend (TH-8180:H-502-42W = 6:4) | 28–45 |

| Co-solvent | 1–5 |

| Wetting agents (BW-104E:HOS 2413 = 2:3) | 0.1–0.5 |

| Drier (OXY-Coat1101) | 5 |

| Adhesion promoter (MOAP 1880) | 1.5 |

3. Results and Discussion

3.1 Resin Selection

The resin blend significantly influenced coating performance. Table 2 compares properties of coatings derived from different resins.

Table 2. Effect of resin type on coating performance

| Resin | Drying Time (min) | Adhesion (Grade) | Water Resistance (h) | Ultrasonic-Chemical Resistance |

|---|---|---|---|---|

| TH-8180 | 40 | 0 | 480 | Partial removal |

| H-502-42W | 25 | 1 | 240 | Partial removal |

| TH-8180 + H-502-42W (6:4) | 34 | 0 | 360 | Minimal removal |

The hybrid resin system achieved a balance between fast drying (34 min) and durability, attributed to the interpenetrating network formed by oxidative crosslinking (TH-8180) and physical stacking (H-502-42W).

3.2 Wetting Agent Optimization

A dual wetting agent system improved surface coverage on rough engine cylinder block surfaces. Table 3 evaluates different combinations.

Table 3. Performance of wetting agent blends

| Blend (Ratio) | Contact Angle (°) | Foam Suppression | Post-Cleaning Adhesion |

|---|---|---|---|

| BW-104E:HOS 2413 (2:3) | 24.7 | Strong | Grade 0 |

| COADD W-110:HOS 2413 (2:3) | 27.0 | Moderate | Grade 1 |

| BYK-340:HOS 2413 (2:3) | 22.2 | Weak | Grade 1 |

The BW-104E:HOS 2413 combination provided optimal wettability and foam control, critical for uniform coating on engine cylinder block.

3.3 Drier and Adhesion Promoter Effects

Table 4 highlights the role of OXY-Coat1101 and MOAP 1880 in enhancing crosslinking and adhesion.

Table 4. Impact of additives on coating properties

| Additive | Hardness (König) | Adhesion (Grade) | Salt Spray Resistance (h) |

|---|---|---|---|

| 5% OXY-Coat1101 | 0.156 | 0 | 336 |

| 1.5% MOAP 1880 | – | 0 | 720 |

The cobalt-free drier accelerated oxidative curing without compromising environmental safety, while MOAP 1880 strengthened interfacial bonding via silane-metal interactions.

4. Application Testing

The optimized coating was applied to cast iron engine cylinder block and subjected to ultrasonic-chemical cleaning (parameters in Table 5).

Table 5. Ultrasonic-chemical cleaning parameters

| Parameter | Value |

|---|---|

| Ultrasonic power (kW) | 16 |

| Frequency (kHz) | 28 |

| Cleaning agent (%) | 5 |

| Temperature (°C) | 60 |

| Duration (min) | 15 |

Post-cleaning evaluation confirmed no delamination or softening, validating the coating’s robustness for engine cylinder block protection.

5. Conclusions

- Resin system: A 6:4 blend of TH-8180 and H-502-42W ensures rapid drying and chemical resistance.

- Wetting agents: BW-104E:HOS 2413 (2:3) achieves low dynamic surface tension and penetrates engine cylinder block microstructures.

- Additives: OXY-Coat1101 (5%) and MOAP 1880 (1.5%) enhance crosslinking density and metal adhesion.

This study provides a scalable solution for durable coatings on engine cylinder block, meeting industrial demands for efficiency and environmental compliance.

6. Future Work

Further research will explore:

- Long-term thermal stability of coatings under engine cylinder block operating conditions.

- Scalability of the formulation for high-volume production.

- Advanced characterization techniques (e.g., SEM, XRD) to analyze coating microstructure.