This article delves deep into the sand treatment system of 3D printing smart casting factories. It comprehensively covers aspects such as the importance of the sand treatment system, its (presented in detail with flowcharts and tables), key equipment (including their functions, types, and characteristics), and the overall impact on the casting production process. By providing in – depth analysis and practical insights, this article aims to offer a thorough understanding of the sand treatment system in 3D printing smart casting factories for professionals and enthusiasts in the field.

1. Introduction

In the realm of modern casting technology, 3D printing has emerged as a revolutionary force, transforming the way sand – based casting is carried out. The sand treatment system in 3D printing smart casting factories plays a crucial role in ensuring the quality of sand – based molds and cores, which directly impacts the final casting products.

Unlike traditional casting methods, 3D printing in casting allows for highly complex geometries and rapid prototyping. However, to fully leverage the benefits of this technology, an efficient sand treatment system is essential. The sand treatment system is responsible for preparing the raw materials, recycling and reusing old sand, and ensuring that the sand used in the 3D printing process meets the required quality standards.

1.1 The Significance of the Sand Treatment System

The sand treatment system serves multiple purposes. Firstly, it provides a continuous supply of high – quality sand to the 3D printers. The quality of the sand, including its particle size distribution, moisture content, and purity, can significantly affect the accuracy and strength of the 3D – printed sand molds and cores. Secondly, by recycling and reusing old sand, it helps to reduce production costs and environmental impact. In traditional casting, a large amount of sand is discarded after use, but in a well – designed sand treatment system, the old sand can be processed and reused, minimizing waste.

1.2 Challenges in the Sand Treatment System for 3D Printing Casting

One of the main challenges is dealing with the unique characteristics of 3D – printed sand molds. The 3D – printed sand molds often have a different structure and strength compared to traditional sand molds. For example, 3D – printed sand molds may have a higher strength due to the way the sand and binder are combined during the printing process. This requires special consideration when designing the sand treatment system, especially in processes such as mold separation and sand recycling.

Another challenge is ensuring the compatibility of different components in the sand treatment system. Since the sand treatment system consists of various equipment such as crushers, magnetic separators, and conveyors, these components need to work in harmony to achieve the desired results. Any mismatch in their performance can lead to inefficiencies in the system.

2. Process Flow of the Sand Treatment System

2.1 New Sand Addition

The addition of new sand is the first step in the sand treatment process. The choice of new sand addition point depends on the quality of the new sand. Table 1 summarizes the different scenarios for new sand addition:

| New Sand Quality | Addition Point | Rationale |

|---|---|---|

| Poor Quality | At the sand falling area | The new sand can be processed throughout the system, and undergo roasting in the thermal regeneration system to improve its quality. |

| Good Quality | After the thermal regeneration sending tank | It can be directly sent to the printer’s buffer sand hopper through the sending system for use. |

2.2 Sand Reclamation from Printed Molds

After the 3D – printed sand molds are cured, the loose sand is cleaned. The sand that falls during the handling and pouring processes can be reused. Reusing old sand can reduce the amount of curing agent required, thus lowering production costs. Figure 1 shows the process flow of sand reclamation from printed molds.

[Insert Figure 1: Process Flow of Sand Reclamation from Printed Molds here. The figure should show the steps from printed mold curing, sand cleaning, to the reuse of the cleaned sand, with arrows indicating the flow direction.]

2.3 Casting and Sand Separation

The sand – cast assembly is poured and cooled, and then sent to the tilting machine for tilting and sand falling. The casting is separated from the sand mold. The fallen sand blocks are conveyed through a series of equipment for further processing. As shown in Figure 2, the sand blocks first pass through a vibrating sand – falling machine, then through a vibrating conveyor and a plate – chain bucket elevator, while passing through a suspended magnetic separator to remove large iron blocks, iron sheets, and burrs.

[Insert Figure 2: Casting and Sand Separation Process Flow here. The figure should clearly illustrate the equipment involved in the process, such as the tilting machine, vibrating sand – falling machine, vibrating conveyor, plate – chain bucket elevator, and suspended magnetic separator, with the flow of sand blocks shown by arrows.]

2.4 Sand Crushing and Magnetic Separation

The sand blocks are then crushed into small particles. A vibrating crusher is commonly used for this purpose. After crushing, the sand passes through a drum magnetic separator to remove small iron beans and iron sheets mixed in the sand. The crushed sand is then stored in a crushed sand bin. Table 2 lists the functions and characteristics of the main equipment in this process:

| Equipment Name | Function | Characteristics |

|---|---|---|

| Vibrating Crusher | Crush sand blocks into small particles | High – efficiency crushing, can adjust the particle size to a certain extent |

| Drum Magnetic Separator | Separate small iron beans and iron sheets from sand | High – precision magnetic separation, can effectively remove magnetic impurities |

2.5 Thermal Regeneration of Sand

If the sand needs to be thermally regenerated, the sand in the crushed sand bin is fed by a screw feeder and passes through a linear screen before entering the thermal regeneration roasting furnace. In the furnace, the organic matter adhered to the sand surface is decomposed by high – temperature roasting, restoring the sand to its state before adding the binder. The roasted sand is then sent to the regenerated sand bin for temporary storage. Figure 3 shows the process flow of thermal regeneration of sand.

[Insert Figure 3: Thermal Regeneration of Sand Process Flow here. The figure should include the equipment such as the screw feeder, linear screen, thermal regeneration roasting furnace, and the flow of sand during the thermal regeneration process.]

2.6 Screening and Supply to the Printer

The roasted sand is screened by a square swing screen to separate impurities and obtain pure regenerated sand. The regenerated sand is then sent to the printer’s buffer sand hopper, where it is mixed with the curing agent in a mixing tank and supplied to the printer for sand core printing. Table 3 shows the types of screening devices and their applications:

| Screening Device | Application Scenarios | Advantages |

|---|---|---|

| Vibration Screen | General screening in resin sand process | High – screening efficiency, suitable for large – scale production |

| Square Swing Screen | Separating impurities from roasted sand | Fine – screening ability, can effectively remove small – sized impurities |

3. Key Equipment in the Sand Treatment System

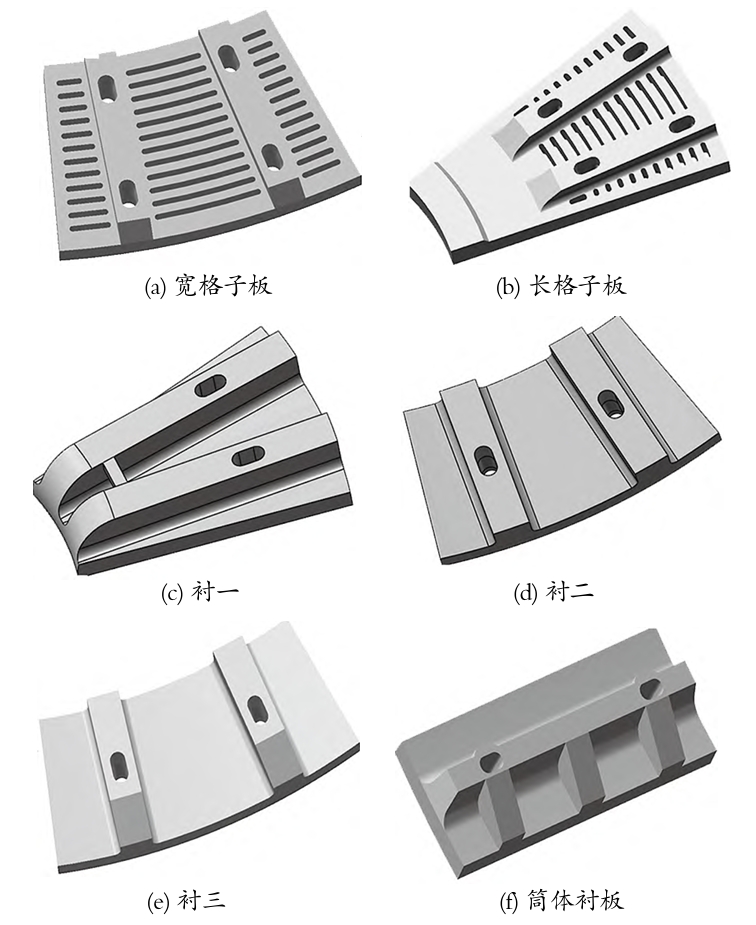

3.1 Sand – Falling Machines

Sand – falling machines are mainly used to break the casting mold and separate the casting from the molding sand. The commonly used sand – falling machines include vibrating sand – falling machines and drum – type sand – falling machines. The vibrating sand – falling machine separates the casting and the molding sand by the periodic vibration of the sand – falling bed, which makes them collide and rub against the bed. Since 3D – printed sand molds have a higher strength than manual – molded sand molds, the performance of the sand – falling machine needs to be carefully considered. Table 4 compares the two types of sand – falling machines:

| Type of Sand – Falling Machine | Working Principle | Advantages | Disadvantages |

|---|---|---|---|

| Vibrating Sand – Falling Machine | Periodic vibration of the sand – falling bed causes collision and friction | High separation efficiency, simple structure | High noise, relatively large wear and tear |

| Drum – Type Sand – Falling Machine | Rotation of the drum makes the casting and sand collide | Gentle separation, less damage to the casting | Low separation efficiency, complex structure |

3.2 Magnetic Separation Equipment

Magnetic separation equipment is used to remove magnetic substances such as broken risers, iron sheets, iron beans, burrs, and chills from the old sand after sand – falling. This is crucial to ensure the quality of the sand mold and prevent equipment damage. There are different types of magnetic separation equipment, such as suspended magnetic separators and drum magnetic separators. The suspended magnetic separator is mainly used to remove large – sized magnetic impurities, while the drum magnetic separator is more suitable for removing small – sized magnetic impurities. Table 5 shows the characteristics of different magnetic separation equipment:

| Type of Magnetic Separation Equipment | Separation Object | Separation Efficiency | Installation Location |

|---|---|---|---|

| Suspended Magnetic Separator | Large – sized magnetic impurities (e.g., large iron blocks, iron sheets) | High for large – sized impurities | Above the conveyor belt during sand transportation |

| Drum Magnetic Separator | Small – sized magnetic impurities (e.g., iron beans, small iron chips) | High for small – sized impurities | After the sand crushing process |

3.3 Thermal Regeneration Equipment

Thermal regeneration equipment is used to roast the sand particles obtained after processes such as mold breaking, cooling, magnetic separation, and screening of the formed sand mold at high temperatures. This makes the binder film on the sand particle surface fall off, and the sand can be reused as new sand. Thermal regeneration can significantly reduce the consumption of new sand and the amount of resin added, bringing obvious economic benefits. The sand processed by thermal regeneration equipment has uniform particle size, low dust content, and high thermal stability, which is conducive to improving the quality of castings. Figure 4 shows a schematic diagram of a typical thermal regeneration equipment.

[Insert Figure 4: Schematic Diagram of Thermal Regeneration Equipment here. The figure should show the main components of the thermal regeneration equipment, such as the furnace body, heating device, and sand – feeding and discharging devices.]

3.4 Screening Devices

In the resin sand process, common screening devices include vibration screens and swing screens. The choice between the two can be determined according to different use environments and efficiency requirements. Vibration screens are suitable for large – scale production with high – screening efficiency, while swing screens are better at fine – screening and separating small – sized impurities. Table 6 compares the performance of vibration screens and swing screens:

| Screening Device | Screening Efficiency | Screening Precision | Suitable for |

|---|---|---|---|

| Vibration Screen | High | Moderate | Separating large – quantity sand with general particle – size requirements |

| Swing Screen | Moderate | High | Separating sand with high – precision particle – size requirements or removing small – sized impurities |

3.5 Conveying Equipment

The sand treatment system uses various types of conveying equipment, mainly divided into mechanical conveying equipment and pneumatic conveying equipment. Mechanical conveying equipment includes vibrating conveyors, screw conveyors, belt conveyors, and bucket elevators. Each type of mechanical conveying equipment has its own characteristics. Pneumatic conveying equipment, on the other hand, has the advantages of dust – free transportation, flexible pipeline layout, and multi – point unloading. Table 7 summarizes the characteristics of different conveying equipment:

| Conveying Equipment Type | Characteristics | Advantages | Disadvantages |

|---|---|---|---|

| Bucket Elevator | Vertical operation, belt – type conveyor | High – lifting height, stable operation | Limited conveying capacity, relatively high energy consumption |

| Belt Conveyor | Large conveying capacity, simple structure, long – distance transportation | Low power consumption | Difficult to move at bends, high maintenance requirements |

| Vibrating Conveyor | Simple structure, reliable operation, fast conveying speed | High – speed transportation | Easy to wear, prone to blockage, high noise |

| Screw Conveyor | Simple structure, strong conveying capacity, stable operation | Can be used for inclined or vertical conveying | Parts are easy to wear, materials are easy to block |

| Pneumatic Conveying Equipment | Closed – pipeline transportation, dust – free, flexible pipeline layout, multi – point unloading | Environment – friendly, flexible | Not suitable for conveying 块状 materials, relatively high energy consumption |

4. Optimization and Future Trends of the Sand Treatment System

4.1 System Optimization

To improve the efficiency and performance of the sand treatment system, several optimization measures can be taken. Firstly, the integration of different equipment should be optimized. By coordinating the operation parameters of crushers, magnetic separators, conveyors, and other equipment, the overall efficiency of the system can be enhanced. For example, adjusting the feeding speed of the crusher according to the conveying capacity of the subsequent conveyor to avoid over – feeding or under – feeding.

Secondly, the control system of the sand treatment system can be upgraded. Using advanced sensors and automation control technology, real – time monitoring of the sand treatment process can be achieved. This allows for timely adjustment of process parameters to ensure the quality of the treated sand. For example, sensors can be installed to monitor the sand particle size, moisture content, and magnetic impurity content, and the control system can automatically adjust the working conditions of the screening device and magnetic separator accordingly.

4.2 Future Trends

With the continuous development of technology, the sand treatment system in 3D printing smart casting factories will also face new trends. One of the trends is the application of artificial intelligence (AI) technology. AI can be used to optimize the operation of the sand treatment system, predict equipment failures, and improve the quality control of the sand treatment process. For example, AI algorithms can analyze historical data of the sand treatment process to predict the wear and tear of equipment, enabling timely maintenance and replacement, reducing downtime.

Another trend is the development of more environmentally friendly sand treatment technologies. As environmental protection requirements become more stringent, new sand treatment technologies that are more energy – efficient and produce less waste will be developed. For example, the development of new thermal regeneration technologies that consume less energy or the exploration of non – thermal regeneration methods.

5. Conclusion

The sand treatment system in 3D printing smart casting factories is a complex and crucial part of the casting production process. From the addition of new sand to the final supply of sand to the 3D printer, each step in the process flow is carefully designed to ensure the quality of the sand – based molds and cores. The key equipment in the sand treatment system, such as sand – falling machines, magnetic separation equipment, thermal regeneration equipment, screening devices, and conveying equipment, all play important roles in different aspects of the sand treatment process.

By optimizing the sand treatment system and keeping up with future trends, 3D printing smart casting factories can improve production efficiency, reduce production costs, and enhance the quality of casting products. As the field of 3D printing and casting technology continues to evolve, the sand treatment system will also continue to develop and innovate to meet the growing demands of the industry.

In summary, a well – designed and efficiently operating sand treatment system is the foundation for the success of 3D printing smart casting factories, and it will play an increasingly important role in the future development of the casting industry.