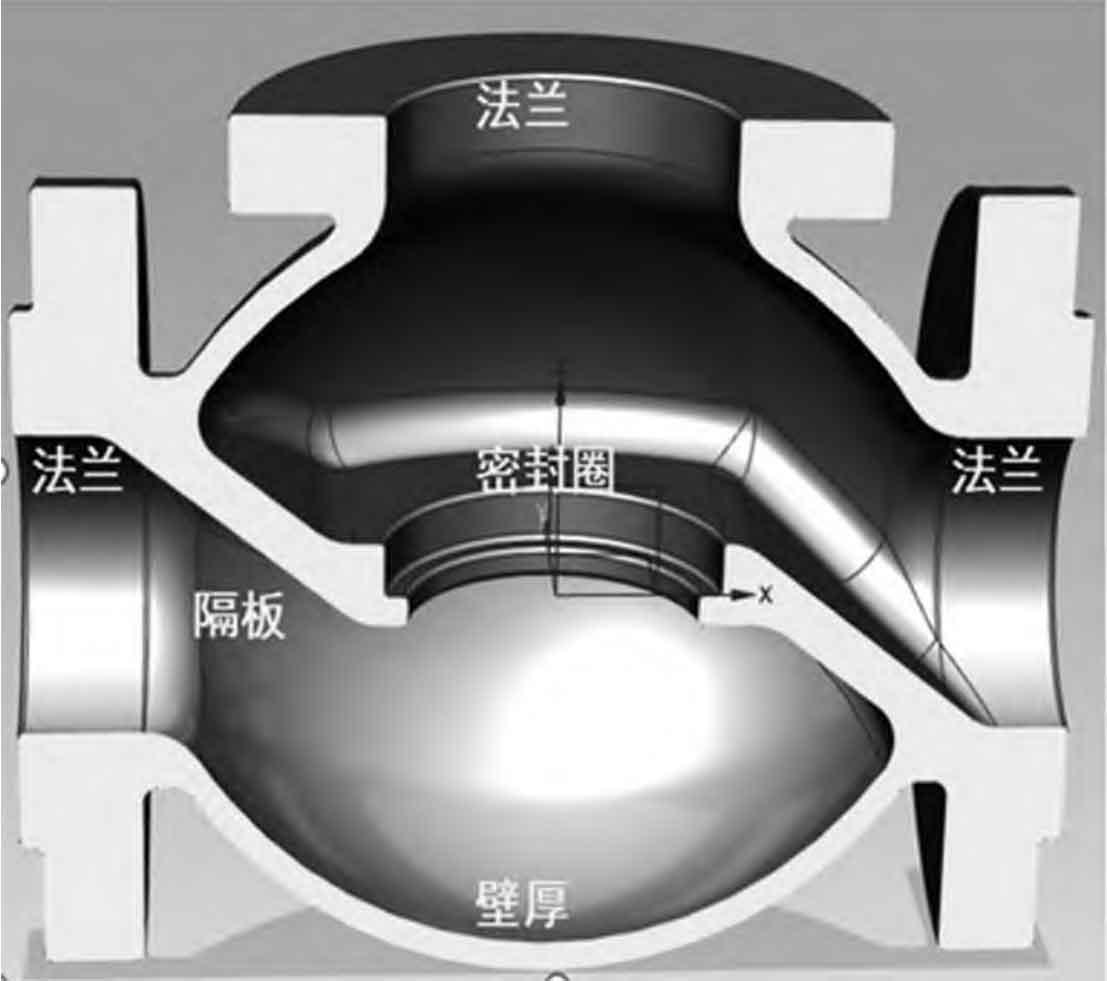

Duplex stainless steel valve body castings are critical components in corrosive environments like marine applications due to their excellent strength-corrosion resistance balance. However, production faces significant challenges with crack defects during solidification and cooling. This analysis examines a case study where eight SA351M-CN3MN valve bodies (DN200, 170kg) exhibited extensive micro-cracks after liquid penetrant testing, revealing systemic issues in material control and processing.

Crack Formation Mechanisms

Cracks initiate when thermal stresses exceed the material’s fracture strength during solidification. For duplex stainless steel valve body castings, this is governed by:

1. Thermal Contraction Stress:

$$ \sigma_{thermal} = \alpha \cdot E \cdot \Delta T $$

where \(\alpha\) is thermal expansion coefficient, \(E\) is Young’s modulus, and \(\Delta T\) is temperature gradient. High \(\Delta T\) across thick-thin section transitions in valve body castings generates critical stresses.

2. Embrittlement Factors:

- Phosphorus-Induced Cold Brittleness: P segregates to grain boundaries, reducing cohesion energy:

$$ G_c = G_0 – k_P \cdot C_P $$

where \(G_c\) is boundary cohesion, \(C_P\) is P concentration. - Sulfur-Induced Hot Tearing: Low-melting FeS films form at grain boundaries above 985°C, reducing high-temperature ductility.

| Element | Upper Limit (wt%) | Mechanism | Control Target |

|---|---|---|---|

| P | 0.04 | Boundary embrittlement | ≤0.035% |

| S | 0.01 | Hot tearing | ≤0.008% |

| C | 0.03 | Chromium carbide precipitation | 0.02-0.025% |

Integrated Prevention Methodology

1. Enhanced Sand Core Design

Core rigidity must balance mold support and contraction allowance. For valve body castings with complex internal geometries:

- Incorporate hollow cores with ceramic fiber reinforcement (density reduction: 25-30%)

- Insert cellulose ropes (5-8mm diameter) at stress concentration zones

- Core permeability >120 GFN to minimize gas pressure

Optimal pouring parameters:

| Parameter | Initial Value | Optimized Value | Effect |

|---|---|---|---|

| Temperature | 1600-1620°C | 1550-1580°C | Reduces δ-ferrite coarsening |

| Pouring Time | 25-30s | 12-16s | Minimizes temperature gradient |

| Gate Velocity | 1.2 m/s | 0.8-1.0 m/s | Decreases turbulent filling |

2. Composition Precision Control

Beyond standard ASTM A351 limits, critical ratios require optimization:

Phase Balance Control:

$$ \text{PREN} = \%\text{Cr} + 3.3 \times \%\text{Mo} + 16 \times \%\text{N} > 40 $$

$$ \text{Ferrite Number } (FN) = 3.34(\%\text{Cr}) – 2.46(\%\text{Ni}) – 28.6 \approx 45-55 $$

Trace element management:

- Ce/S > 1.5 to form stable Ce2O3-Ce2S3 compounds

- N/C ratio >500 to suppress Cr23C6

3. Rare Earth (RE) Modification

Adding 0.5% mischmetal (45% Ce, 25% La, 20% Nd) achieves:

Grain Refinement:

$$ d = \frac{k}{\sqrt{\dot{T}}} + d_0(\text{RE}) $$

where \(d\) is grain size, \(\dot{T}\) is cooling rate, \(d_0\) is base size reduced by RE nuclei.

Inclusion Modification:

$$ \text{MnS} + 2\text{Ce} \rightarrow \text{Ce}_2\text{S}_3 + \text{Mn} $$

$$ \Delta G^\circ = -35 \text{kJ/mol} \quad (\text{at 1500°C}) $$

| Parameter | Untreated | RE-Treated | Improvement |

|---|---|---|---|

| Inclusion Density (/mm2) | 42 ± 8 | 18 ± 3 | -57% |

| Average Inclusion Size (μm) | 12.5 | 3.2 | -74% |

| Crack Initiation Sites | 28% | 6% | -79% |

4. Thermal Management During Finishing

Post-casting operations induce thermal shocks in duplex structures:

Riser Removal:

$$ T_{\text{cut}} < \frac{T_{\text{brittle}} + T_{\text{service}}}{2} = \frac{475 + 100}{2} = 287^\circ\text{C} $$

Water-jet cutting maintains cut-zone temperature below 100°C.

Repair Welding Protocol:

- Interpass temperature ≤100°C

- Heat input control:

$$ Q = \frac{\eta \cdot V \cdot I}{v} \leq 1.2 \text{kJ/mm} $$

where \(\eta\)=0.8 (efficiency), \(V\)=voltage, \(I\)=current, \(v\)=travel speed - Shielding gas: 98%Ar + 2%N2

Implementation Results

After implementing these measures in subsequent valve body casting production batches:

- Crack occurrence reduced from 100% to <1.5%

- Ultrasonic testing pass rate increased to 98.7%

- Ferrite-austenite phase ratio stabilized at 52:48 ±3%

- Charpy impact energy increased by 40% at -46°C

The comprehensive approach demonstrates that synergistic control of metallurgical and processing parameters enables reliable production of defect-free duplex stainless steel valve body castings for critical applications.