Our concentrator processes polymetallic ores, primarily zinc-tin, through three grinding systems. System A and B each utilize a primary Φ2700×3600 grid-type ball mill paired with a secondary Φ2400×3000 ball mill. System C employs a Φ4500×2400 semi-autogenous grinding (SAG) mill and a Φ3200×4000 ball mill. Persistent issues plagued the Φ2700×3600 ball mills, particularly concerning their lining plates: short service life, difficult structural adjustments, prolonged replacement cycles, and localized wear. These problems compromised operational stability, increased maintenance complexity, and disrupted planned maintenance schedules.

1 Performance Deficiencies of Manganese Steel Lining Plates

Historically (2014-2018), manganese steel lining plates were used. They presented significant drawbacks:

1.1 Short Lifecycle, Excessive Weight, Replacement Difficulty

The service life averaged only 8-9 months, necessitating frequent maintenance. A full set weighed 23.48 tonnes, with individual plates ranging from 100 kg to 200 kg. This weight, combined with confined installation spaces, made handling hazardous and replacement slow (5-6 days), impacting availability and increasing injury risks.

1.2 Excessive Noise Generation

Direct impact between grinding media (steel balls) and the manganese steel lining plates generated high noise levels. Annual monitoring (2018) showed an average noise level of 92.38 dB(A), exceeding the occupational exposure limit of 85 dB(A) (Table 1).

| Month | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Noise dB(A) | 91.2 | 92.3 | 94.3 | 96.2 | 94.9 | 92.4 | 93.6 | 90.7 | 91.3 | 90.8 | 91.2 | 89.7 |

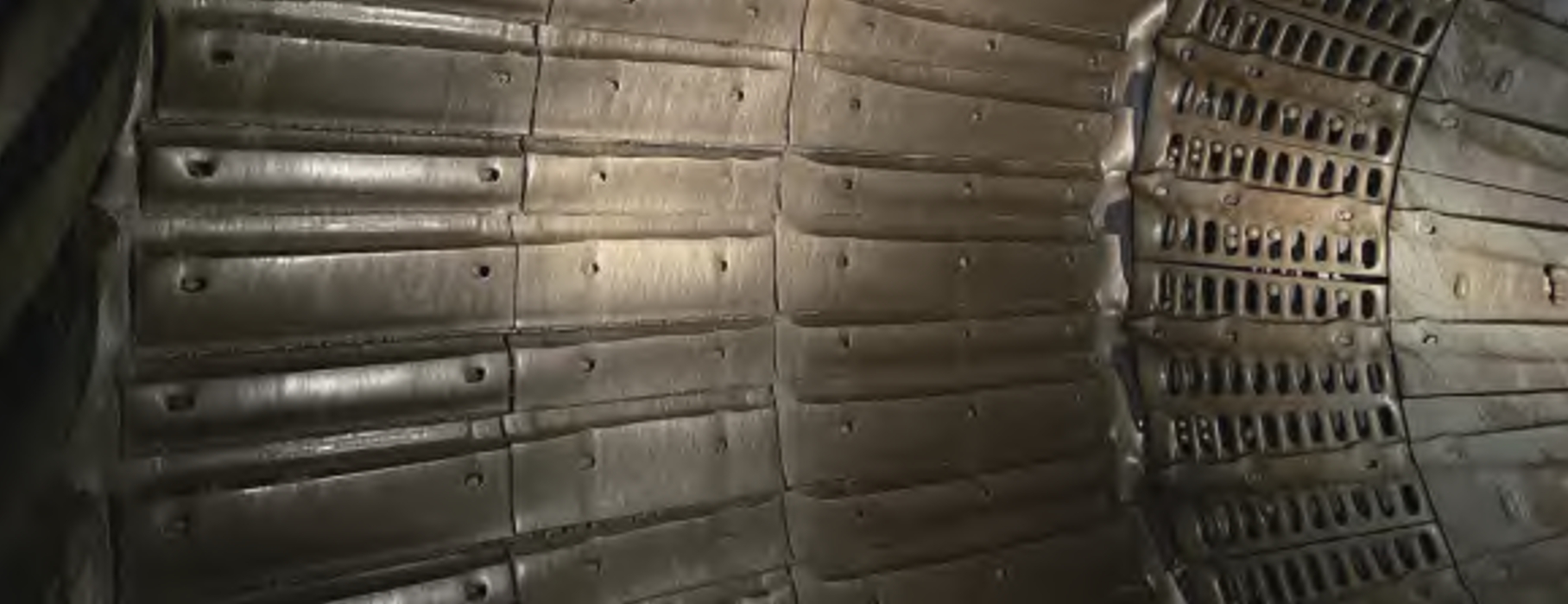

1.3 Performance Instability and Fragmentation

The material exhibited poor impact resistance. Vigorous collisions within the mill caused unpredictable fracturing and premature failure (Figure 1). This unreliability necessitated unplanned shutdowns for inspection, increasing costs and disrupting production. The lifecycle ($T_m$) was highly variable:

$$T_m = f(P_{\text{ore}}, H_{\text{hardness}}, I_{\text{impact}}) \pm \epsilon_{\text{high}}$$

where $\epsilon_{\text{high}}$ represents the significant uncertainty due to fragmentation.

1.4 Poor Sealing and Leakage

Low elastic deformation and rapid wear caused frequent slurry leakage at bolt points, requiring unplanned stops for tightening. This reduced equipment availability ($A$):

$$A = \frac{\text{Operating Time}}{\text{Operating Time + Downtime}} \times 100\%$$

Frequent motor starts/stops also shortened motor lifespan.

2 Introduction and Limitations of Monolithic Rubber Composite Lining Plates

In 2018, monolithic rubber composite lining plates replaced manganese steel, offering improvements but revealing new challenges.

2.1 Enhanced Installation and Weight Reduction

The full set weight decreased to 15.05 tonnes, with individual plates weighing ≤ 70 kg. Installation required only manual handling (2-3 workers), reducing replacement time to 4 days and significantly lowering injury risk.

2.2 Noise Reduction

The rubber dampened impact noise. Annual monitoring showed a reduced average of 88.28 dB(A) (Table 2), improving the working environment.

| Month | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Noise dB(A) | 88.05 | 89.30 | 88.10 | 87.10 | 89.10 | 87.65 | 89.60 | 87.40 | 89.80 | 89.20 | 87.75 | 88.50 |

2.3 Improved Sealing

Better elasticity minimized leakage, eliminating ~40 hours/year of downtime for bolt tightening.

2.4 Short Lifespan of Feed/Discharge End Shell Plates

The monolithic rubber lining plates used a wave structure for the shell. The feed and discharge end shell plates suffered particularly rapid wear, lasting only 3-6 months and often requiring partial replacement. This caused irregular maintenance schedules and increased confined space entry risks.

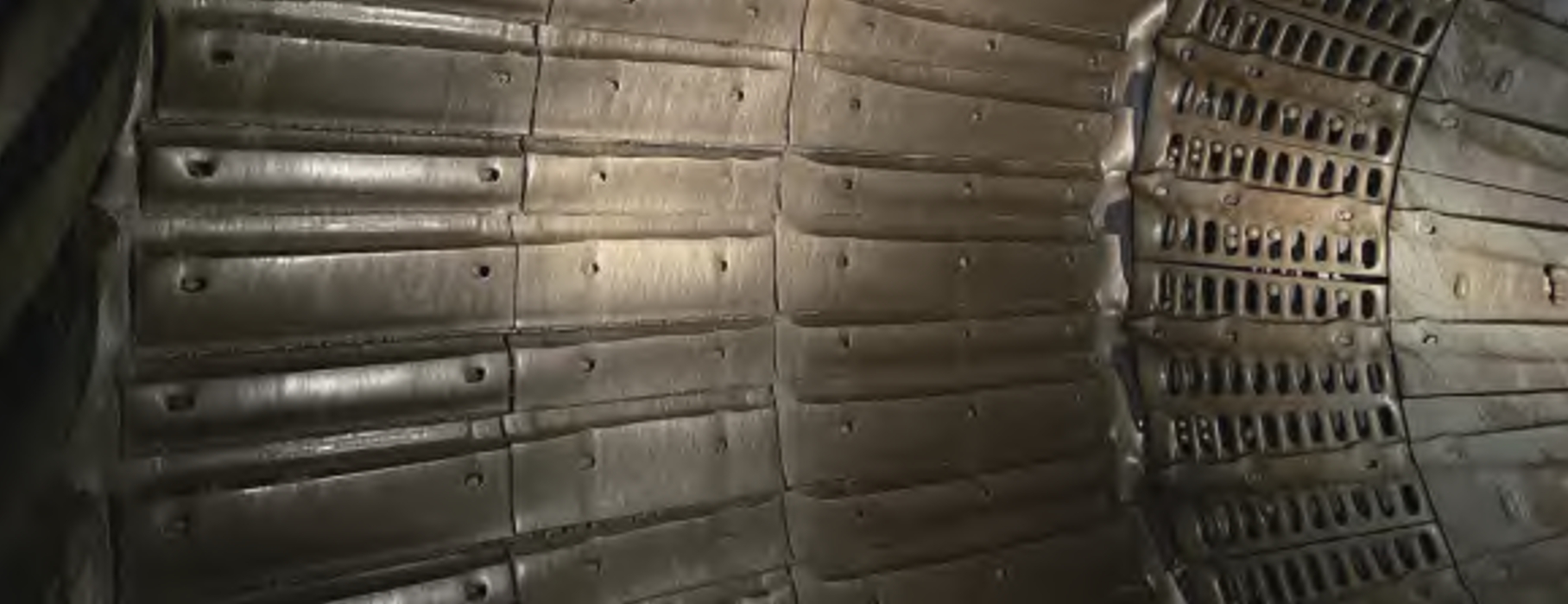

3 Application and Advantages of Split Shell Lining Plates

In 2021, a split design shell lining plate was introduced for the Φ2700×3600 mills. This design decouples the lifter bars from the backing plates. Lifters are bolted directly, while the backing plates are secured by the lifter’s stepped profile.

A comparative trial was conducted:

* System A: Monolithic Rubber Composite lining plates (Wave Shell)

* System B: Rubber Composite lining plates (Split Shell Design)

Results demonstrated significant advantages for the split lining plate design:

3.1 Reduced Weight and Maintenance Time

Single split shell plates weighed 47-53% less than monolithic wave plates; lifters weighed 30-69% less. This facilitated handling, reducing replacement time to 3 days and lowering labor costs and risks.

3.2 Extended Service Life and Increased Availability

The lifespan of feed/discharge end plates increased from ≤6 months to ≥10 months. Replacement frequency dropped from 4 times/year to once/year, saving over 108 hours of downtime annually. This directly boosted equipment availability ($A$).

3.3 Lower Power Consumption

Under identical ore and process conditions, System B (split lining plates) operated at 30 kW lower power than System A, indicating improved grinding efficiency:

$$\Delta P = P_{\text{A}} – P_{\text{B}} = 30 \text{ kW}$$

3.4 Reduced Maintenance Costs

Wear predominantly affects lifters at the feed/discharge ends. The split design allows replacing only worn lifters, reusing the backing plates. This yielded substantial cost savings:

$$\text{Annual Saving} = (C_{\text{full set}} – C_{\text{lifters only}}) \times N_{\text{replacements avoided}}$$

Quantified savings exceeded ¥70,000/year per mill.

4 Conclusion

Our operational experience demonstrates that for small grid-type ball mills processing zinc-tin ore, rubber composite lining plates outperform manganese steel lining plates in lifespan, weight, noise, and sealing. Crucially, the split shell lining plate design significantly surpasses the monolithic wave structure. It delivers extended service life (≥10 months for critical zones), reduced maintenance time (3 days), lower power consumption (30 kW savings), and decreased component replacement costs (>¥70,000/year/mill) by enabling lifter-only replacement. This split lining plate configuration offers a robust solution for enhancing reliability and cost-efficiency in mineral grinding circuits.