The relentless pursuit of high performance, low emissions, and improved fuel efficiency in the automotive industry has made weight reduction a paramount concern. As vehicle weight directly impacts fuel economy, the use of lightweight materials has become a critical pathway. Among these, aluminum alloy die castings are the preferred choice due to their excellent mechanical properties, good formability, and significant weight-saving potential. Their applications span structural housings, engine components, and various other automotive parts. The annual growth of aluminum die casting production is robust, accounting for over 75% of non-ferrous alloy die castings. This growth is driven by the trend towards larger, more complex, thinner-walled, and highly integrated components, which in turn pushes the advancement of die casting technologies. However, a persistent and critical challenge in this field is the formation of internal defects, primarily shrinkage in casting, which severely compromises the mechanical integrity and pressure tightness of the final parts.

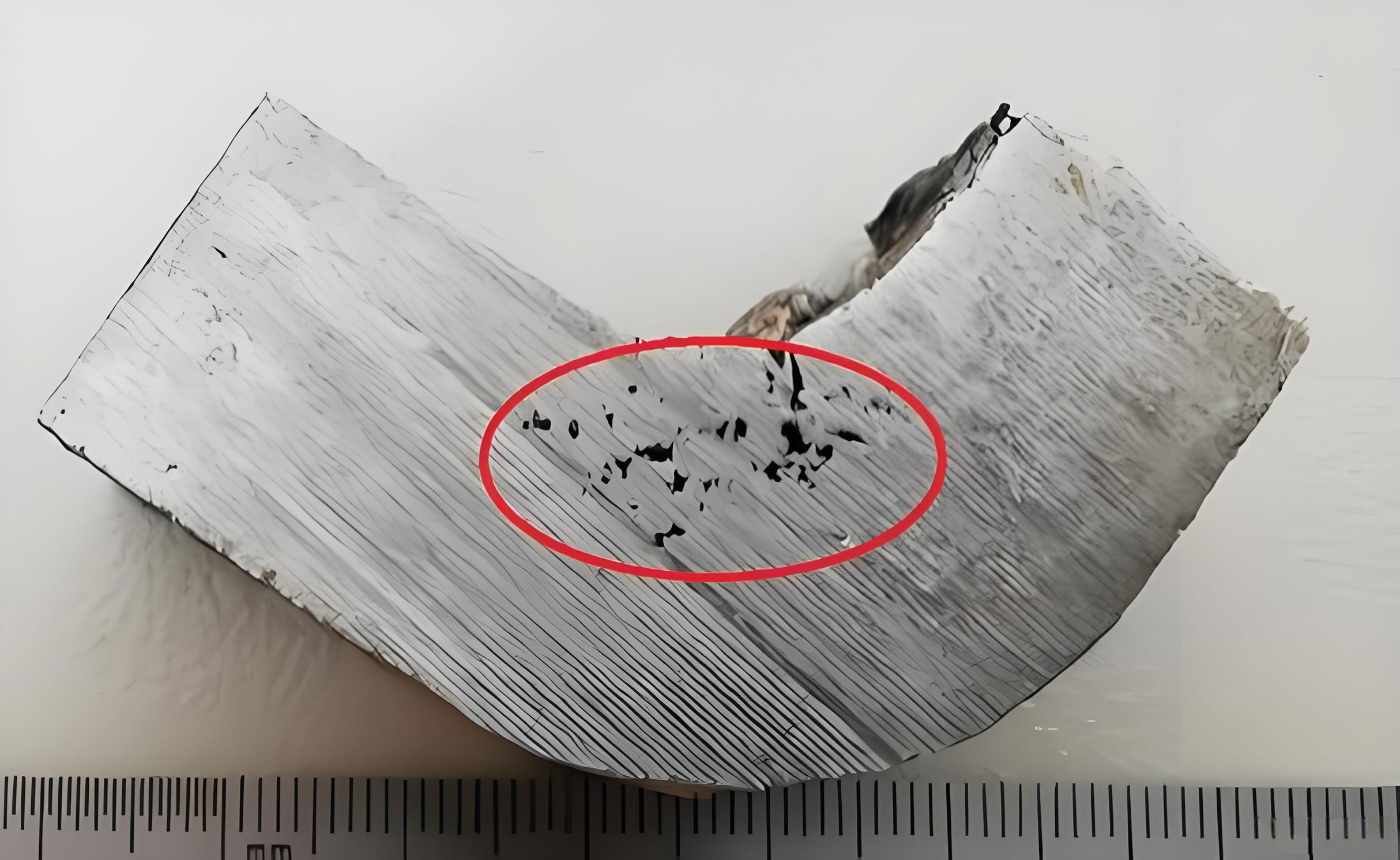

Shrinkage in casting defects, including both macro-shrinkage cavities and micro-shrinkage porosity, are inherent to the solidification process of metals. In aluminum die castings, these defects predominantly manifest in the thermal centers of thick sections or isolated heavy mass areas. Macroscopically, they appear as irregular cavities. Under microscopic examination, the morphology reveals dark, rough, and dendritic surfaces within the pores, a clear signature of shrinkage formation during the last stages of solidification where liquid metal feeding is insufficient. This lack of feeding leads to the formation of voids, significantly degrading tensile strength, elongation, and especially pressure tightness—a critical property for many automotive components like housings and covers. A particular challenge is that small-scale shrinkage in casting is often difficult to detect reliably with standard X-ray inspection, making its prevention through process and design control even more crucial.

Die casting is a complex synergy of machine, mold (die), and alloy, governed by the interplay of pressure, velocity, temperature, and time. Optimizing these parameters is essential to manage the solidification sequence and mitigate defects. Therefore, beyond considering the casting’s design, die sophistication, and alloy properties, meticulous control over the process parameters is vital. The following sections detail several advanced and practical technologies developed to combat shrinkage in casting in aluminum die castings.

1. Localized Squeeze Pin Technology

This is a highly effective active feeding technique designed to eliminate shrinkage in casting at its source. The principle involves integrating hydraulic cylinders within the die that actuate precision pins. These pins are positioned to act upon specific thick sections of the casting just as the metal transitions into a mushy, semi-solid state. By applying sustained high pressure directly to the solidifying region, the squeeze pin compensates for volumetric shrinkage by forcing additional liquid metal into the porous region, effectively “healing” the incipient void.

The successful implementation of a squeeze pin system requires careful engineering of several key parameters:

- Location & Design: The pin can act on the casting’s exterior (leaving a protrusion to be machined off), directly form an interior feature like a pre-cast hole, or act on a heavy portion of the overflow or gating system to promote directional feeding.

- Squeeze Pressure (P_extrusion): This must be significantly higher than the intensification pressure during casting to overcome the flow resistance in the semi-solid network. It is typically 3-5 times the casting pressure.

- Pin Diameter (D_pin): Determines the area over which pressure is applied and influences the volume of metal displaced.

- Squeeze Depth (Stroke): Directly related to the volume of metal needed to compensate for shrinkage in the specific thermal center.

- Timing: The most critical operational parameters. Delay Time is the interval between the end of cavity fill and the start of pin movement. It must be precisely set so the pin acts when the target area is semi-solid. Duration Time is how long the pin holds pressure, which must be sufficient for the gate and the squeezed area to fully solidify.

The required hydraulic cylinder diameter is calculated based on the system hydraulic pressure and the desired squeeze pressure on the pin. The force balance is given by:

$$F_{cylinder} = F_{extrusion} \implies P_{cylinder} \cdot \pi \left(\frac{D_{cylinder}}{2}\right)^2 = P_{extrusion} \cdot \pi \left(\frac{D_{pin}}{2}\right)^2$$

Where \( P_{cylinder} \) is the available hydraulic system pressure (e.g., 16 MPa), \( P_{extrusion} \) is the target pressure on the semi-solid metal (e.g., 300 MPa), \( D_{pin} \) is the squeeze pin diameter, and \( D_{cylinder} \) is the calculated cylinder piston diameter. Proper cooling of the squeeze pin via targeted spray is essential to prevent thermal fatigue and bending.

| Parameter | Description | Typical Value / Consideration |

|---|---|---|

| Action Location | Position of the pin relative to the part. | Exterior surface, interior core, or gating system. |

| Squeeze Pressure (P_extrusion) | Pressure exerted on the semi-solid metal. | 300 – 500 MPa (3-5x casting pressure). |

| Pin Diameter (D_pin) | Diameter of the active squeeze pin. | Defined by feature size and required feed volume. |

| Hydraulic Pressure (P_cylinder) | Machine’s available hydraulic pressure. | Typically 12-20 MPa. |

| Cylinder Diameter (D_cylinder) | Required piston diameter to achieve P_extrusion. | Calculated from force balance equation. |

| Delay Time | Time from fill end to pin actuation. | 0.5 – 2.0 s (critical, determined empirically). |

| Duration Time | Time pin holds pressure. | 5 – 15 s (ensures solidification under pressure). |

| Squeeze Depth | Stroke length of the pin. | Determined by volumetric shrinkage of the hot spot. |

2. High-Pressure Point Cooling Technology

When die geometry restricts the use of squeeze pins, particularly for deep, narrow cores forming threaded holes or bosses, high-pressure point cooling becomes a vital passive strategy to reduce shrinkage in casting. Traditional cooling lines operate at relatively low pressure (∼0.4 MPa) and cannot effectively cool small-diameter cores. High-pressure point cooling systems utilize pressures of 1.0 MPa or higher, forcing coolant (typically deionized water to prevent scaling) through very small channels (as small as 3 mm in diameter) drilled directly into or behind the core pin.

The principle is one of rapid heat extraction. By intensely cooling the core, the solidification front is accelerated radially outward from the core surface. This promotes directional solidification towards the bulk of the casting and, more importantly, creates a thicker “skin” or sound layer of fine-grained, dense material around the core before the central thermal mass begins to solidify. This sound layer can often contain the shrinkage in casting porosity within a non-critical zone or eliminate it entirely by shifting the porous region to an overflow. The system is often coupled with timer-controlled valves to precisely manage the cooling cycle, turning coolant flow on and off at optimal moments in the casting cycle to maximize die life and thermal stability.

| Feature | Conventional Cooling | High-Pressure Point Cooling |

|---|---|---|

| Operating Pressure | Low (∼0.4 MPa) | High (≥1.0 MPa) |

| Minimum Channel Diameter | ∼6 mm | ∼3 mm or less |

| Coolant | Standard Industrial Water | Deionized/Purified Water (Essential) |

| Control | Manual Valves, Continuous Flow | Solenoid Valves with Timer Control |

| Primary Function | General Die Temperature Balance | Targeted, Aggressive Cooling of Specific Cores/Features |

| Effect on Shrinkage | Indirect, through overall thermal balance | Direct, by creating a rapid solidification front and a thick sound layer. |

3. Part Design Optimization: Profiling and Weight Reduction

The most cost-effective solution to shrinkage in casting is to eliminate the condition that promotes it: the isolated heavy thermal mass. During the product design phase, structural optimization using profiling techniques is paramount. This involves redesigning thick sections by adding internal pockets, ribs, or conformal (profiled) cavities that follow the external contours. This “hollowing out” reduces the effective section thickness without compromising structural stiffness, thereby breaking up large thermal centers into smaller ones that solidify more uniformly and are easier to feed.

For example, a massive boss for multiple bolt holes can be redesigned with a recessed back, transforming a severe hot spot into a more manageable ribbed structure. Similarly, around pre-cast holes for threading, adding circular relief grooves or recesses isolates the hole’s thermal mass from the main wall, preventing the formation of a shrinkage pipeline. This proactive design approach not only mitigates shrinkage in casting but also contributes directly to the primary goal of weight reduction.

4. Minimizing Machining Allowance

The surface layer of a die casting, often called the “skin,” is the densest and hardest region due to rapid chilling against the die wall. This skin is highly resistant to shrinkage in casting porosity. A common root cause of leakage in critical features like oil galleries is that subsequent machining operations cut through this sound skin, exposing the underlying, potentially porous structure.

A strategic countermeasure is to minimize or even eliminate machining in high-integrity areas. This can be achieved by:

- Reducing Draft Angles on Cores: For deep holes, using a minimal draft angle (e.g., 0.5° instead of 1° or more) dramatically decreases the machining allowance needed to achieve the final diameter, preserving more of the as-cast sound layer.

- Implementing “Near-Net-Shape” or “No-Machining” Zones: For non-critical flat surfaces or secondary bolt holes adjacent to sealed passages, specifying that they remain in the as-cast condition protects the integrity of the surrounding material. This requires tighter control over the die casting process to meet dimensional and flatness requirements without machining.

The benefit is clear: by preserving the sound as-cast surface, the path for leakage through interconnected shrinkage in casting porosity is blocked. The mechanical performance of the part is thus reliant on the quality achieved in the casting process itself, incentivizing further optimization of techniques like squeeze pins and point cooling.

5. Scientific Die Thermal Management

A thermally balanced die is the foundation of consistent, high-quality castings. Uncontrolled temperature gradients directly lead to non-uniform solidification rates, creating isolated hot spots that are prone to severe shrinkage in casting. Modern die thermal management moves beyond simple water lines to a science-based approach:

- Simulation-Driven Design: Using CAE software (e.g., MAGMA, FLOW-3D) during the mold design phase to predict solidification patterns and identify potential hot spots. Cooling channels (for water) and heating channels (for oil) are then strategically placed to extract heat from hot areas and add heat to cold areas.

- Dynamic Control & Verification: During die try-out and production, infrared thermal imaging cameras are used to map the actual temperature distribution on the die surface. This data validates the simulation and guides fine-tuning of coolant flow rates through manual or automatic valves. The goal is to maintain a uniform and optimal die working temperature across every cycle.

The underlying principle is a dynamic heat balance per casting cycle, which can be conceptually expressed as:

$$ \int_{cycle} Q_{in} \, dt = \int_{cycle} Q_{out} \, dt $$

Where \( Q_{in} \) represents the heat input from the molten aluminum and any cartridge heaters, and \( Q_{out} \) represents the heat extracted by cooling channels, thermal radiation, and conduction to the mold base. By actively managing this balance, the solidification front can be directed to proceed smoothly from the farthest point back to the feeders or overflows, minimizing the conditions for shrinkage in casting formation.

| Technology | Mechanism of Action | Primary Application | Key Consideration |

|---|---|---|---|

| Localized Squeeze Pin | Active feeding by applying high pressure to semi-solid thermal center. | Isolated heavy sections, thick bosses, pre-cast holes. | Critical timing, high maintenance, requires hydraulic system integration. |

| High-Pressure Point Cooling | Passive rapid solidification via intense cooling of cores/features. | Deep cores, threaded hole bosses, areas with geometry constraints. | Requires purified water, risk of channel clogging, timer control essential. |

| Design Profiling & Weight Reduction | Eliminates the thermal mass (hot spot) at the design stage. | New product development, redesign of problematic areas. | Most cost-effective long-term solution, requires early design involvement. |

| Minimized Machining Allowance | Preserves the dense, sound as-cast surface layer. | Critical sealing surfaces, pressure-retaining walls, deep holes. | Demands high precision in the die casting process; tight draft angles. |

| Scientific Die Thermal Management | Controls solidification sequence via balanced die temperature. | Fundamental for all castings, especially large/complex parts. | Requires simulation and thermal monitoring equipment for optimization. |

6. Conclusion and Integrated Approach

Mitigating shrinkage in casting in aluminum alloy die castings is not a challenge with a single solution. It requires a holistic, multi-faceted strategy that spans the entire product lifecycle—from initial design to final process control. The most robust approach integrates these technologies synergistically:

- Design First: Optimize the component geometry to minimize inherent thermal centers through profiling and intelligent ribbing.

- Process Simulation: Utilize solidification modeling to predict shrinkage in casting locations and proactively design the feeding (overflows, gates) and cooling systems.

- Targeted Active/Passive Solutions: Apply localized squeeze pin technology for major, accessible hot spots. Implement high-pressure point cooling for difficult-to-reach cores and features.

- Protect Structural Integrity: Specify minimal machining allowances on critical sealing surfaces to preserve the sound as-cast skin.

- Stabilize the Process: Employ scientific die thermal management using simulation and infrared monitoring to achieve and maintain a stable, balanced die temperature cycle after cycle.

The fight against shrinkage in casting is central to producing high-integrity, leak-free, and structurally sound aluminum die castings for demanding applications like automotive powertrains. By understanding the root causes and deploying a combination of these advanced technical strategies, significant improvements in internal quality, yield, and part performance can be consistently achieved.