In my extensive experience within the foundry industry, I have consistently observed that casting holes, often referred to as sand inclusions or sand holes, represent one of the most pervasive and challenging defects in iron castings, particularly when using green sand molding for medium-sized components. Even with the adoption of high-density molding techniques, the occurrence of these defects remains a significant concern, impacting productivity, cost, and final product quality. This article, written from my firsthand perspective, delves deep into the nature of casting holes, providing a detailed methodological framework for their discrimination and a robust set of preventive strategies centered on sand quality management and process optimization. My goal is to offer practical, actionable insights that can be directly applied on the foundry floor to mitigate this costly issue.

Casting holes are fundamentally defined as voids or cavities within or on the surface of a casting that are filled with sand particles. Their formation can be traced to two primary, distinct mechanisms, each requiring a unique diagnostic and corrective approach. The first mechanism involves the dislodgement and subsequent falling of sand grains or clusters into the mold cavity during the interval between mold completion and the commencement of pouring. The second mechanism involves the erosion and entrainment of sand from the mold walls or gating system by the flowing molten iron during the pouring process itself. Accurately distinguishing between these two origins is the critical first step in implementing an effective corrective action plan.

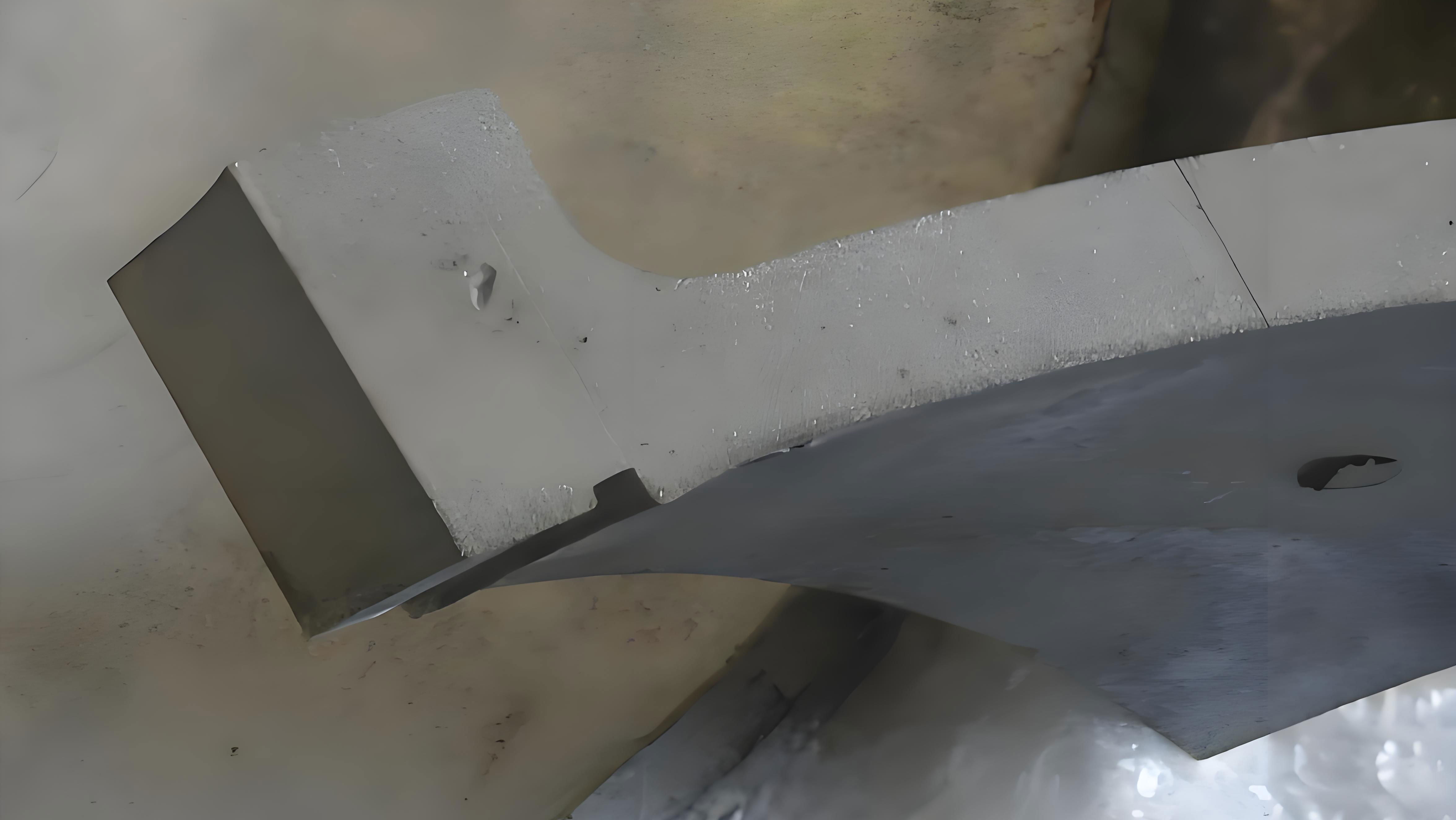

The sand particles from the first cause—pre-pour fallout—typically exhibit minimal chemical interaction with the molten iron, carbon, and silicon oxides. Consequently, they largely retain their original angular shape and morphology when examined in the defect. In contrast, the sand particles entrained during pouring are subjected to prolonged contact and severe thermal and chemical assault from the molten metal. This results in significant alteration; their original form is often destroyed, becoming rounded, sintered, or partially dissolved, and they are frequently surrounded by a reaction layer. This fundamental difference in appearance under magnification serves as the key diagnostic feature.

To systematically address the first type of casting holes—those from pre-pour sand fallout—the focus must be on meticulous process control throughout the molding, coring, and closing sequence. From my observation, the majority of such incidents stem from improper handling during core setting and mold closing. Inadequate core print clearances, misalignment due to wear in core-setting machines, closing machines, or locating pins, and rough handling can all cause the breakage of mold or core edges, with debris falling into the cavity. A rigorous operational discipline is non-negotiable. Furthermore, attention must be paid to the finishing of copes. The upper surfaces of open risers and vent passages must be carefully smoothed and compacted with a trowel to prevent loose, friable sand from later collapsing inward. For dry sand or chemically bonded molds, applying a refractory wash to the top surfaces of pouring basins and risers can prevent sand grains from being dislodged by air currents or vibration. Finally, the method of cleaning the cavity before closing is paramount. Using suction systems powered by compressed air is vastly superior to blowing with air pressure, as the former effectively removes debris rather than simply redistributing it. After mold closure, covering the pouring cups with thin metal plates is a simple yet highly effective final barrier against accidental contamination.

The prevention of the second, more dynamic type of casting holes—those caused by sand erosion and entrainment during pouring—demands a dual-front strategy involving advanced sand system control and intelligent gating design. This is where the core of technical management lies.

Sand Quality Management: The Foundation of Prevention

The properties of the molding sand are the first line of defense against erosive casting holes. Based on my work, three factors are paramount: the control of microfines, the strategic use of additives, and proper mulling practice.

The content of dead clay, ash, and fine particles below 75 microns, collectively termed “microfines,” has a profound impact on sand behavior. An excessive buildup, typically beyond 10-12%, is detrimental. It necessitates higher water addition to achieve target compactability, which in turn increases the water-to-bentonite ratio (often expressed as moisture content divided by compactability). This leads to a brittle, friable sand that lacks durability and is highly susceptible to erosion. The relationship can be summarized by the following key parameters:

The wet compressive strength ($S_w$) and the water ratio ($R_w$) are critical functions of the microfines content ($C_m$). While the exact relationship is system-dependent, the trend is universally negative beyond an optimal point.

$$ R_w = \frac{W}{C_p} $$

where $W$ is the moisture content (%) and $C_p$ is the compactability (%). High $R_w$ correlates directly with increased brittleness and a higher incidence of casting holes.

Empirical data from countless tests show that maintaining $C_m$ below 10% is crucial for stability. The table below summarizes the effects:

| Microfines Content ($C_m$) | Wet Strength ($S_w$) | Water Ratio ($R_w$) | Sand Character & Defect Risk |

|---|---|---|---|

| < 10% | Optimal, stable | Lower, stable | Durable, resilient. Low risk of casting holes. |

| 10% – 15% | Declining | Increasing | Becoming friable. Moderate risk of casting holes. |

| > 15% | Poor, unpredictable | High | Very brittle, weak. High risk of casting holes and other defects. |

To enhance the surface stability of the sand without resorting to higher, detrimental moisture levels, the addition of starches is a powerful tool. Starch, particularly in its pre-gelatinized (alpha) form, coats sand grains and bentonite, improving cohesion and the sand’s resistance to metal penetration and erosion at the mold-metal interface. The effectiveness is a function of the addition rate ($A_s$) and the gelatinization degree ($G_d$). The surface stability ($SS$) improvement can be modeled as:

$$ SS \propto A_s \cdot G_d $$

For high-pressure molding sands, an addition of 0.5% to 1.5% of a high-gelatinization starch is typically recommended to significantly reduce the propensity for casting holes formation.

Furthermore, adequate mulling or preparation time is essential. Pre-mixing the sand allows for complete hydration and development of the bentonite’s bonding potential, effectively increasing the “available” bentonite content. This results in higher, more consistent green strength and superior surface stability, directly combatting the mechanisms that lead to casting holes.

Process and Gating System Design: Direct Intervention

Even with excellent sand, the hydrodynamic forces during pouring can be immense. Intelligent design is required to manage these forces and prevent the creation of casting holes.

The implementation of ceramic foam filters has been a revolutionary step in my practice. Placed in the gating system, typically in the runner close to the ingates, they serve a dual purpose. Their three-dimensional porous structure acts as a mechanical sieve, trapping loose sand grains and slag particles. Perhaps more importantly, they drastically reduce turbulence and moderate the metal velocity, transforming a turbulent flow into a more laminar one before it enters the mold cavity. This significantly lowers the erosive potential on the mold walls. The pressure drop ($\Delta P$) across a filter can be approximated using a form of the Darcy-Forchheimer equation for flow through porous media:

$$ \Delta P = \frac{\mu v L}{k_1} + \frac{\rho v^2 L}{k_2} $$

where $\mu$ is dynamic viscosity, $v$ is velocity, $L$ is filter thickness, $\rho$ is density, and $k_1$, $k_2$ are permeability coefficients. This impedance is beneficial for flow control.

The design of the ingate is another critical lever. For a given runner height, a thinner ingate presents a smaller “target” for eroded sand to pass through. Experience dictates that for small to medium castings, an ingate thickness in the range of 2-4 mm is ideal for minimizing the passage of sand and thus preventing casting holes. Furthermore, the use of a non-pressurized or marginally pressurized gating system is preferred. If a pressurized system is used, the ingates should be designed in an expansion pattern (e.g., sprue area < runner area < ingate area) to reduce the velocity and impact force of the metal stream as it enters the cavity.

The placement of ingates must be carefully considered to avoid direct impingement on mold walls or cores, which is a prime cause of localized erosion and subsequent casting holes. Multiple, well-distributed ingates that promote smooth, progressive filling are superior to a few high-velocity streams.

For larger castings produced in chemically bonded sand molds, such as furan resin, the combustion of the binder at the onset of pouring can weaken the sprue. A common and effective remedy I employ is the use of refractory ceramic tubes for the sprue, often combined with bottom gating, to entirely eliminate sprue erosion as a source of casting holes.

An often-overlooked detail is the pouring bush or basin. In one notable instance involving large machine tool castings (> 2000 kg) made in dry sand molds, scattered casting holes appeared across upper sections of castings. The root cause was traced not to the main mold, but to the dry-sand pouring basin itself, whose base had been eroded away during pouring. The simple switch to a more refractory, loam-lined or pre-formed ceramic pouring basin completely eliminated this source of casting holes.

Advanced Filtration and Molten Metal Treatment

Beyond in-mold filters, treating the molten iron itself to remove inherent inclusions can synergistically reduce the overall load that might contribute to defect formation. The use of advanced filtration ceramics, such as low-temperature sintered mullite foam filters, represents a significant advancement. These filters are not only effective at removing non-metallic inclusions but also help in reducing turbulence. The filtration efficiency ($E_f$) for particles above a critical size can be described as:

$$ E_f = 1 – \exp(-\beta L) $$

where $\beta$ is a filter coefficient dependent on porosity and pore size, and $L$ is thickness. Implementing such filtration consistently improves metal cleanliness, reduces the potential for casting holes related to entrapped slag or dross, and can lead to measurable improvements in mechanical properties by reducing stress concentrators.

The economic impact of casting holes is staggering. Considering the annual global production of iron castings, even a single percentage point reduction in scrap rate attributable to casting holes translates to massive savings in energy, materials, and labor. The cost-benefit analysis of implementing robust sand control and advanced gating/filtration often shows a very favorable return on investment, not only through defect reduction but also via improved machinability and higher yield.

Integrated Prevention Strategy: A Summary Table

A holistic approach is necessary. The following table consolidates the primary causes of casting holes and their corresponding prevention measures, forming a ready reference for foundry engineers.

| Root Cause of Casting Holes | Key Characteristics | Primary Prevention Measures | Supporting Technical Actions |

|---|---|---|---|

| Pre-Pour Sand Fallout | Sand grains retain original shape; located randomly; often associated with cope features. | 1. Precision in core setting and mold closing. 2. Proper core print design and tooling maintenance. 3. Careful finishing of riser tops. 4. Cavity cleaning by suction, not blowing. 5. Covering pouring cups after closing. |

Use of accurate jigs and fixtures; operator training; visual standards for mold closure. |

| Erosion & Entrainment During Pouring | Sand grains are deformed, sintered; often found near ingates or flow paths; may show reaction layers. | Sand Management: 1. Control microfines content (<10%). 2. Add alpha-starches (0.5-1.5%). 3. Ensure adequate mulling/pre-mixing. Process Design: 4. Use ceramic foam filters in runners. 5. Employ thin or expanding ingates (2-4mm). 6. Avoid direct impingement of metal stream. 7. Use ceramic sprue tubes for large bonded molds. 8. Use refractory pouring basins. |

Regular sand testing (AFS Clay, Methylene Blue, Compactability); gating system simulation software; filter performance testing. |

| Inherent Molten Metal Inclusions | Defects may contain complex oxides, slag; not purely silica sand. | 1. Use of efficient ladle treatment and slag removal practices. 2. Implementation of in-stream filtration (e.g., foam ceramic filters). |

Metal treatment training; cleanliness standards; monitoring of furnace and ladle linings. |

In conclusion, the battle against casting holes in iron castings is won through a combination of vigilant process control, scientific sand management, and innovative gating design. From my perspective, there is no single “silver bullet.” It requires a systematic approach that begins with accurate defect diagnosis to identify the root cause—whether the sand fell in or was washed in. Once identified, a targeted set of actions, from controlling the fundamental properties of the molding sand to redesigning the path the molten metal takes, can be deployed with high effectiveness. The persistent application of these principles, coupled with ongoing monitoring and a culture of continuous improvement, will significantly reduce the incidence of casting holes, leading to higher quality castings, reduced costs, and enhanced competitiveness for any foundry. The journey to eliminate casting holes is continuous, but with the right knowledge and tools, it is a highly achievable goal.