In my extensive experience with Lost Foam Casting (LFC), the development and application of the coating are arguably the most critical factors determining final casting quality. Unlike traditional casting methods, the coating in LFC serves a dual, and often conflicting, purpose: it must provide a robust barrier between the molten metal and the unbonded sand, while simultaneously allowing the rapid escape of gases produced from the vaporization of the foam pattern. Failure to balance these properties—strength and permeability—invariably leads to defects, with casting holes being among the most prevalent and troublesome. These casting holes can manifest as gas pores, sand inclusions, or penetrations, each traceable back to coating performance. This article details my first-hand journey in formulating, testing, and refining LFC coatings, with a specific focus on the scientific principles and practical adjustments necessary to eradicate these costly defects.

The fundamental challenge lies in the coating’s response to the extreme thermal and mechanical events during pouring. As molten metal replaces the polystyrene (EPS) foam, the coating is subjected to intense heat, rapid gas generation, and the hydrodynamic pressure of the metal stream. A coating with excessive permeability but insufficient hot strength will allow metal penetration into the sand, causing mechanical burn-on and sand erosion, which are direct precursors to sand-related casting holes. Conversely, a coating with high strength but low permeability will trap pyrolysis gases, leading to blowholes and gas porosity—another form of casting holes. Therefore, the design goal is not to maximize either property in isolation, but to optimize their synergy for a specific alloy and casting geometry.

1. Coatings Formulation Design: A Component-Based Analysis

The coating is a complex suspension system. My development process involved systematic variation of key components to map their individual and combined effects on the critical slurry and dried-layer properties.

1.1 Refractory Base

The refractory filler provides the primary thermal barrier. Alumina-silicate materials like calcined bauxite (aluminous earth) are cost-effective for iron and steel castings. The particle size distribution (PSD) is paramount. Finer powders (e.g., 320 mesh) promote a smooth casting surface but can reduce permeability. Coarser powders (e.g., 240 mesh) enhance gas venting but risk metal penetration. For severe service conditions or high-alloy steels, incorporating fused silica or chromite sand can improve thermal shock resistance. The volume fraction of refractory $\phi_r$ directly influences slurry density and coating thickness. A common starting point is a refractory content of 45-55% by weight of the slurry.

1.2 Binder System

The binder network grants the dry coating its mechanical integrity. A composite binder system is essential:

- Inorganic Binders: Colloidal grades of bentonite (2-4%) provide green strength and improve slurry stability via thixotropy.

- Organic Binders: These are crucial. Latex emulsions (e.g., white latex) and polyvinyl alcohol (PVA) solutions provide room-temperature strength. Cellulose-derived binders like Carboxymethyl Cellulose (CMC, ~0.3%) enhance rheology and contribute to strength. During pouring, these organics pyrolyze, deliberately increasing the coating’s permeability at high temperatures. The total organic binder content is typically 2-5%.

The relationship between binder content $C_b$ and coating strength $\sigma_c$ can be approximated by:

$$\sigma_c \propto k \cdot C_b^n$$

where $k$ is a constant dependent on binder type, and $n$ is an exponent typically between 1 and 2, indicating a non-linear strengthening effect.

1.3 Additives and Carrier

Minor additives fine-tune performance. Wetting agents (e.g., Tween-80 at ~0.05%) reduce surface tension, ensuring the slurry uniformly coats the hydrophobic foam. Defoamers (e.g., n-butanol) are necessary to control air entrainment during mixing. For ferrous castings, especially ductile iron, carbonaceous defects (lustrous carbon) can be mitigated by adding small amounts (~0.1%) of fluxing agents like cryolite ($Na_3AlF_6$), which forms active fluorides that absorb free carbon. Water is the standard carrier; its quantity determines slurry viscosity and density.

1.4 Summary of Experimental Formulations and Outcomes

The following table summarizes key formulations tested and the resulting defects, clearly linking improper coating properties to the formation of casting holes.

| Trial No. | Key Variation from Baseline | Primary Coating Property Deviation | Observed Defect in Casting | Root Cause Related to Casting Holes |

|---|---|---|---|---|

| 1 | High organic binder, coarse refractory | Excessively High Permeability | Mechanical burn-on, sand adhesion | Metal penetrates weak, porous coating, encapsulating sand grains. Upon cleaning, these pockets leave behind sand-filled casting holes. |

| 5 | Very high binder content, fine refractory | Excessively High Strength, Low Permeability | Gas porosity (blowholes), difficult coating removal | Trapped pyrolysis gases from foam decomposition cannot escape, forming gas-type casting holes (pores) within the casting. |

| 8 (Optimal) | Balanced composition (see Section 4) | Optimal Strength & Permeability | Good surface finish, coating peeled easily | Gases vented effectively while metal was contained, preventing both gas and sand casting holes. |

| 10 | Low binder content | Insufficient Strength | Veining/fins, sand inclusions | Coating cracked under thermal or mechanical stress during vibration or pouring, allowing direct metal-sand contact and creating sand-induced casting holes. |

The optimal composition derived from this empirical study for general-purpose ferrous castings is as follows: Refractory (Calcined Bauxite, 100 parts), Bentonite (3 parts), Composite Organic Binder (Latex/CMC/PVA blend, total ~7.5 parts), Wetting Agent (0.1 parts), Defoamer (0.04 parts), Flux Additive (0.1 parts), with water added to achieve a working viscosity of approximately 40-50 seconds using a #4 Zahn cup.

2. Application, Drying, and Process Control

A perfect formulation is ineffective without controlled application. The coating must be applied evenly to achieve a consistent thickness $t_c$, which is a primary process variable. For gray and ductile iron, $t_c = 0.8 – 1.2\,mm$ is typical. For higher-temperature alloys like steel, $t_c = 1.5 – 2.0\,mm$ is necessary to resist thermal erosion. Dip, flow, or spray methods can be used, but for complex patterns, a flow-coating process combined with rotation ensures uniform coverage without pooling.

Drying must be gentle and uniform to prevent cracking. For water-based coatings, a temperature of $50 \pm 2^\circ C$ in a forced-air circulation oven is ideal. Rapid drying at high temperatures creates steam pressure within the coating layer, leading to micro-cracks that become pathways for metal penetration, directly causing casting holes.

3. Solving Defects: From Analysis to Corrective Action for Casting Holes

The transition from trial batches to production revealed specific issues, each requiring a targeted solution rooted in coating science.

3.1 Carbon Defects in Ductile Iron Castings

Problem: Black, carbonaceous smut on the upper surfaces of ductile iron castings.

Analysis: Ductile iron’s high carbon content reduces its ability to absorb additional carbon from EPS pyrolysis. Dense foam patterns exacerbate this by leaving more carbon residue. A perfectly permeable coating allows these carbon particles to deposit on the metal surface.

Solution: A multi-pronged approach was essential. First, the coating formulation was modified by adding 0.1% cryolite. At high temperatures, it decomposes:

$$2Na_3AlF_6 \rightarrow 6NaF_{(g)} + 2AlF_{3(g)}$$

These gaseous fluorides react with and assimilate free carbon, preventing its deposition. Second, foam pattern density was reduced, and hollow sprue and runner systems were adopted to minimize the total mass of decomposing polymer, thereby reducing the gas load and carbon potential.

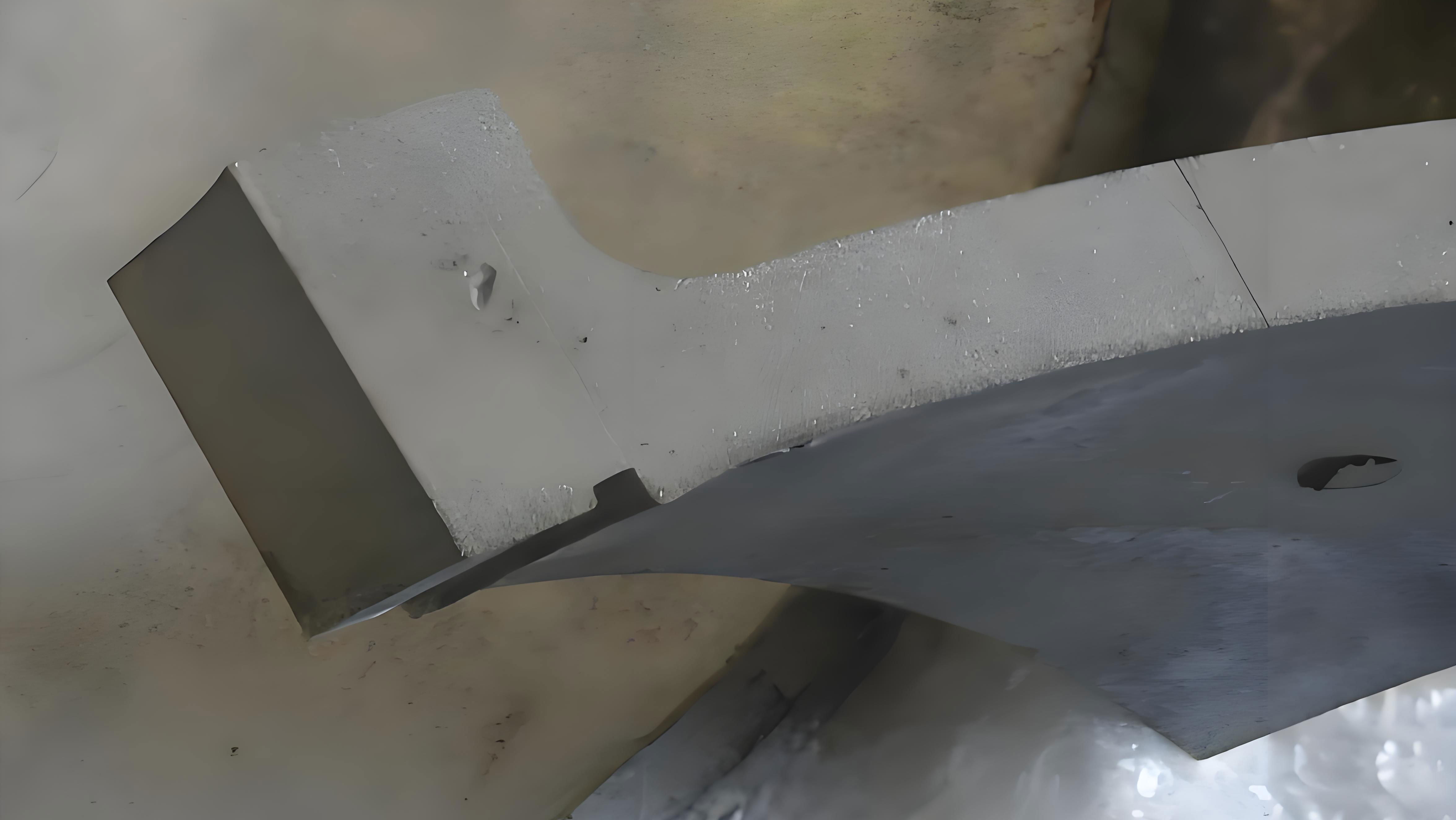

3.2 Burn-on and Sand Penetration in Steel Castings

Problem: Localized metal penetration into the coating, resulting in a fused sand layer that is difficult to remove—a classic sand-based casting hole defect.

Analysis: The standard coating thickness ($\sim 1.0\,mm$) was insufficient for the higher pouring temperatures and longer metal residence times of steel. The thermal shock was more severe.

Solution: The coating thickness for all steel castings was increased to the $1.5 – 2.0\,mm$ range. Furthermore, the refractory base was upgraded. For general steel castings, a finer (320 mesh) bauxite was used to improve particle packing. For high-demand applications, a blend of 50% 320 mesh bauxite and 50% fused alumina (brown corundum) was employed. The corundum’s higher refractoriness ($Al_2O_3 > 95\%$) and thermal conductivity provided a much more resistant barrier, effectively sealing the mold and preventing the initiation of casting holes through metal penetration.

3.3 Veining, Fins, and Sand Inclusions

Problem: Thin metal projections (fins) in parting lines or sand inclusions within the casting body.

Analysis: This defect pointed directly to coating failure under mechanical stress. During mold vibration compaction or the initial surge of metal, a weak coating can fracture. Metal intrudes into these cracks, solidifying as fins or washing loose sand into the cavity, creating isolated sand casting holes.

Solution: The root cause was inadequate coating preparation. The slurry requires sufficient mixing time (4-5 hours) in a rotary mixer (rolling) to fully develop the binder’s adhesive properties and achieve a stable, thixotropic state. Furthermore, implementing routine quality checks on the batched slurry was non-negotiable. The control parameters are summarized below:

| Control Parameter | Target Range | Measurement Method | Consequence of Deviation |

|---|---|---|---|

| Slurry Density | 1.65 – 1.75 g/cm³ | Weight/Volume Cup | Too low: Thin coating, weakness. Too high: Poor application, cracking. |

| Application Viscosity | 40 – 50 sec (#4 Zahn) | Zahn Cup | Too low: Runs, thin spots. Too high: Poor coverage, lumps. |

| Mixing Time | > 4 hours | Process Timer |

Slurry must be used within 20-30 minutes of mixing to prevent settling or rheological changes. Applying coating while continuously agitating the slurry pot is critical to maintain consistency.

4. Advanced Analysis: Coating Permeability and Gas Dynamics

To deeply understand the formation of gas-related casting holes, one must model the gas dynamics during pouring. The foam decomposition generates a gas volume $V_g$ at a rate $\dot{V}_g$ which must flow through the coating’s porous structure and the sand aggregate. Darcy’s Law for flow through a porous medium provides insight:

$$v = -\frac{k}{\mu} \frac{\Delta P}{L}$$

Where $v$ is the superficial gas velocity, $k$ is the intrinsic permeability of the coating layer, $\mu$ is the gas viscosity, $\Delta P$ is the pressure drop across the coating, and $L$ is the coating thickness ($t_c$).

A critical condition for preventing gas-driven casting holes is that the gas pressure $P_g$ at the metal-coating interface must remain below the local metallostatic pressure $P_m = \rho_m g h$ and the coating’s fracture strength $\sigma_f$.

$$P_g < \min(P_m, \sigma_f)$$

If $P_g$ exceeds $P_m$, metal flow is impeded or gas bubbles are forced into the solidifying metal, creating porosity (casting holes). If $P_g$ exceeds $\sigma_f$, the coating cracks, leading to sand invasion (casting holes). Therefore, the coating’s role is to provide a high enough permeability $k$ to keep $P_g$ low, while maintaining sufficient $\sigma_f$.

The permeability $k$ of the dried coating is not constant; it increases with temperature $T$ as organic binders burn out:

$$k(T) = k_0 + \alpha \cdot \exp(-\beta / T)$$

where $k_0$ is the initial permeability, and $\alpha$, $\beta$ are constants related to the binder’s pyrolysis characteristics. An ideal coating has a moderate $k_0$ to handle initial gas release and a rapidly increasing $k(T)$ to vent the main gas volume, all while the refractory skeleton maintains its structural integrity.

5. Integrated Process Optimization for Defect-Free Castings

Eliminating casting holes requires viewing the coating as one component in a synergistic system. Key interactions include:

- Foam Pattern Quality: Using low-density EPS or co-polymer (STMMA) patterns reduces total gas generation $\dot{V}_g$, lowering the demand on coating permeability.

- Gating System Design: Hollow sprues and runners minimize gas source volume. Ensuring smooth metal flow without turbulent impingement on the coating (e.g., avoiding sharp turns in the gating) protects the coating from mechanical erosion.

- Sand System: Using rounded, uniformly graded sand (e.g., 30/50 mesh) improves overall mold permeability, providing a secondary escape path for gases and reducing back-pressure on the coating.

- Pouring Practice: A swift, non-interrupted pour promotes rapid and steady metal advance, creating a favorable pressure gradient for gas expulsion ahead of the metal front.

In conclusion, the successful elimination of casting holes in Lost Foam Casting is an exercise in systems engineering centered on the coating. It demands a formulation that carefully balances strength and permeability, precise control over application and drying parameters, and a holistic understanding of its interaction with the foam pattern, gating design, and molding aggregates. The optimized coating composition and practices detailed here—emphasizing controlled permeability, adequate thickness for the alloy being poured, and rigorous slurry process control—form a robust foundation for producing high-integrity castings free from the costly and persistent problem of casting holes.