The pursuit of precision and long-term stability in machine tools is a fundamental challenge for the manufacturing industry. As the foundational “mother machine,” the accuracy and reliability of a machine tool are directly dictated by the quality of its core components, the machine tool castings. Any dimensional instability in these castings, often caused by the release of residual stresses during service, compromises the machining accuracy and its stability. For years, a performance gap has existed between domestic and international advanced levels in the stability and reliability of castings used in high-end machine tools. This gap primarily manifests in the inability to maintain micron-level precision over extended periods, a critical requirement for modern manufacturing.

My journey in developing a material solution for high-stiffness, low-stress CNC machine tool castings has evolved through three distinct phases of HT300 gray iron. Each phase represented a significant shift in compositional philosophy, moving towards a paradigm that prioritizes casting integrity and inherent stability over mere strength numbers. This evolution provides a compelling case study on optimizing iron chemistry for demanding structural applications.

The first-generation material was characterized by a low Carbon Equivalent (CE) and a low Silicon-to-Carbon ratio (Si/C). This approach was traditional, aiming to achieve the specified tensile strength through a lower carbon content, which typically promotes a finer pearlite matrix. However, this often came at the cost of increased casting sensitivity, higher shrinkage tendency, and consequently, elevated residual stresses. The second generation shifted to a high CE but maintained a relatively low Si/C ratio. This improved castability and reduced shrinkage, but the potential for maximizing graphite morphology and minimizing undercooling was not fully realized. The breakthrough came with the third generation: a synergistic combination of high Carbon Equivalent and high Silicon-to-Carbon ratio, further enhanced with strategic micro-alloying. This composition has demonstrated superior overall performance, particularly in the critical metrics of elastic modulus, stress reduction, and sectional uniformity.

The systematic comparison of these three material philosophies is summarized in the tables below. The data represents averages from multiple furnace batches to ensure statistical significance.

| Material Category | Furnace Batches | Chemical Composition (wt.%) | CE (%) | ω(Si)/ω(C) | |||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Alloys (Sn, Cr, N) | ||||

| Low CE, Low Si/C HT300 | 40 | 3.08 | 1.66 | 0.85 | 0.03 | 0.08 | Trace Cu, Sb | 3.64 | 0.54 |

| High CE, Low Si/C HT300 | 100 | 3.22 | 1.85 | 0.87 | 0.03 | 0.07 | 0.04% Cr | 3.85 | 0.58 |

| High CE, High Si/C HT300 | 100 | 3.04 | 2.33 | 0.75 | 0.03 | 0.08 | 0.06% Sn, 0.25% Cr, 0.0087% N | 3.83 | 0.77 |

The performance data reveals a clear trend. While all three compositions meet the HT300 tensile strength requirement, the high CE, high Si/C variant achieves a remarkable combination of properties.

| Material Category | Tensile Strength (MPa) | Elastic Modulus (GPa) | Test Bar Hardness (HBW) | Guideway Hardness (HBW) |

|---|---|---|---|---|

| Low CE, Low Si/C HT300 | 332.0 | 120.6 | 203.4 | 189.4 |

| High CE, Low Si/C HT300 | 342.4 | 122.5 | 213.5 | 186.4 |

| High CE, High Si/C HT300 | 369.9 | 132.5 | 223.8 | 205.8 |

The improvement in elastic modulus, from approximately 120 GPa to over 130 GPa, is particularly significant for machine tool castings. A higher modulus translates directly into greater stiffness, reducing deflection under cutting forces and improving dynamic stability. The convergence of test bar and guideway hardness in the high Si/C material also indicates excellent sectional sensitivity, meaning the properties are consistent from thin to thick sections—a critical attribute for complex machine tool castings with varying wall thicknesses.

The metallurgical quality parameters further confirm the superiority of the advanced composition. These parameters are calculated as follows:

$$ \text{Carbon Equivalent (CE)} = \%C + \frac{1}{3}(\%Si + \%P) $$

$$ \text{Eutectic Saturation (S_c)} = \frac{\%C}{4.26 – \frac{1}{3}(\%Si + \%P)} $$

$$ \text{Maturity (RG)} = \frac{\text{Actual Tensile Strength (MPa)}}{1000 \cdot (1.73 – 2.93 \cdot S_c)} $$

$$ \text{Hardening Capacity (HG)} = \frac{\text{Actual Hardness (HBW)}}{1000 \cdot (4.95 – 7.00 \cdot S_c)} $$

$$ \text{Quality Index (Qi)} = \frac{RG}{HG} $$

A maturity (RG) greater than 1.0 indicates the iron is performing above the theoretical baseline for its composition. A hardening capacity (HG) close to or below 1.0 suggests a low tendency to form hard chill or mottled structures. The high CE, high Si/C material excels in these indices.

| Material Category | Eutectic Saturation (S_c) | Maturity (RG) | Hardening Capacity (HG) | Quality Index (Qi) |

|---|---|---|---|---|

| Low CE, Low Si/C HT300 | 0.83 | 0.99 | 0.65 | 1.52 |

| High CE, Low Si/C HT300 | 0.89 | 1.18 | 0.79 | 1.49 |

| High CE, High Si/C HT300 | 0.88 | 1.22 | 0.80 | 1.52 |

Metallographic analysis provides the microstructural foundation for these property improvements. The high CE, high Si/C material exhibits a near-ideal microstructure for machine tool castings: over 99% well-formed, blunt-ended Type A graphite (size 4-5) uniformly distributed in a matrix of more than 99% fine pearlite. The high Si/C ratio promotes graphite formation and growth in a favorable manner, reducing undercooling. The addition of tin (Sn) powerfully stabilizes pearlite, preventing ferrite formation. Chromium (Cr) refines the pearlite lamellar spacing and increases hardness uniformity, while nitrogen (N) aids in graphite nucleation and matrix strengthening. The pearlite interlamellar spacing is significantly refined, contributing to higher strength and stiffness.

The most critical validation for machine tool castings is the measurement of residual stress. Using a standardized stress frame, the residual stresses in the thick section were measured. The results clearly show the benefit of the high CE, high Si/C approach in minimizing locked-in stresses, which are the primary cause of long-term dimensional instability in service.

| Material Category | Residual Stress at Thick Section, σ₁ (MPa) | Residual Stress at Thick Section, σ₂ (MPa) |

|---|---|---|

| Low CE, Low Si/C HT300 | +32.4 | +17.2 |

| High CE, Low Si/C HT300 | +20.2 | -6.7 |

| High CE, High Si/C HT300 | +25.0 | +5.8 |

Based on this comprehensive development work, we have established a definitive set of target specifications for high-end CNC machine tool castings.

| Parameter Category | Target Specification |

|---|---|

| Chemical Composition | CE: 3.80–3.90%; Si/C Ratio: 0.70–0.80; N: 0.0080–0.0100%; Sn: 0.04–0.06%; Cr: 0–0.25% |

| Microstructure | Graphite: ≥90% Type A, size 4-5, blunt/curved; Matrix: ≥98% Pearlite; Phosphide/Carbide: ≤1% |

| Mechanical Properties | Tensile Strength: ≥300 MPa; Elastic Modulus: ≥130 GPa; Guideway Hardness: 200 ±10 HBW |

| Metallurgical Quality | Maturity (RG) ≥1.0; Hardening Capacity (HG) ≤1.0; Quality Index (Qi) ≥1.0 |

| As-Cast Residual Stress | Tensile Stress < 50 MPa; Compressive Stress < 98 MPa |

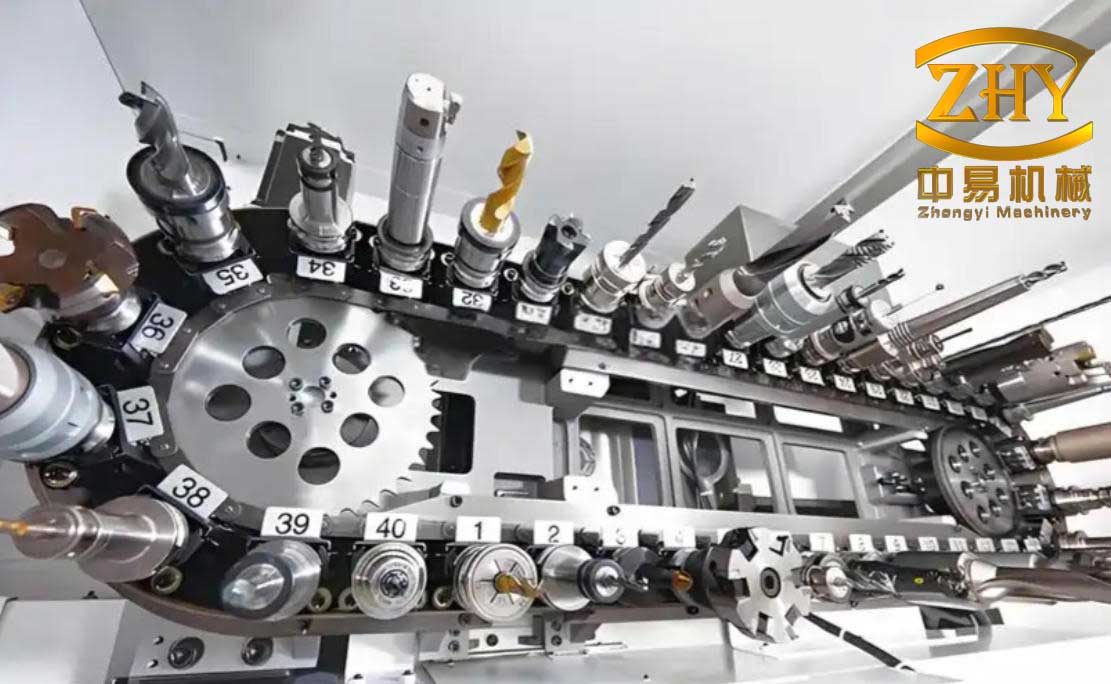

Production Application on a Bed Casting

This material technology was implemented in the production of a critical bed casting for a machining center. The successful application on this component validates the laboratory findings in a real-world, complex geometry typical of machine tool castings.

The bed casting measures approximately 1800 mm x 1000 mm x 900 mm with a weight of 1300 kg. Its wall thickness varies from 15 mm to 80 mm, presenting a classic challenge for sectional uniformity. The material specification was HT300 with additional requirements for guideway hardness (180-210 HBW) and a microstructure dominated by Type A graphite.

The molding process utilized furan resin sand for both molds and cores. Single-cast test bars (Ø30 mm) were produced according to standard practice for quality control. The melting process was meticulously controlled using a medium-frequency induction furnace and a synthetic iron approach.

Key Melting Practice Steps:

- Use of medium-temperature graphitizing carburizer (1.4-1.6% addition).

- Addition of metallurgical silicon carbide (0.6-1.2%) for inoculation and superheating.

- Primary inoculation with 75% FeSi (0.4% addition).

- Stream inoculation with fine 75% Si powder (0.05-0.1% addition).

- Nitrogen addition via manganese-nitride ferroalloy (0.06-0.12%).

- Superheat temperature: 1500-1540°C; Pouring temperature: 1360-1390°C.

- Shakeout temperature strictly below 280°C to minimize thermal stress.

The chemical composition from six consecutive production heats consistently met the target window, demonstrating good process control.

| Heat No. | CE (%) | ω(Si)/ω(C) | C (%) | Si (%) | N (%) | Sn (%) |

|---|---|---|---|---|---|---|

| 1 | 3.80 | 0.79 | 3.00 | 2.37 | 0.0089 | 0.070 |

| 2 | 3.81 | 0.79 | 3.00 | 2.38 | 0.0086 | 0.070 |

| 3 | 3.82 | 0.77 | 3.03 | 2.33 | 0.0079 | 0.070 |

| 4 | 3.81 | 0.80 | 3.00 | 2.39 | 0.0090 | 0.061 |

| 5 | 3.83 | 0.76 | 3.05 | 2.31 | 0.0081 | 0.056 |

| 6 | 3.82 | 0.78 | 3.02 | 2.36 | 0.0076 | 0.067 |

The mechanical properties from single-cast test bars were excellent, comfortably exceeding the 300 MPa requirement and achieving the target elastic modulus of over 130 GPa. Importantly, the guideway hardness on the actual casting was uniform and within the specified 200 ±10 HBW range.

| Heat No. | Tensile Strength (MPa) | Elastic Modulus (GPa) | Test Bar Hardness (HBW) | Guideway Hardness (HBW) – 3 Points |

|---|---|---|---|---|

| 1 | 357 | 133 | 218 | 209, 210, 206 |

| 2 | 366 | 130 | 223 | 206, 202, 210 |

| 3 | 382 | 132 | 225 | 199, 205, 208 |

| 4 | 356 | 137 | 220 | 208, 205, 202 |

| 5 | 374 | 131 | 220 | 201, 198, 197 |

| 6 | 382 | 137 | 232 | 204, 209, 213 |

Microstructural analysis on samples taken from the guideway of the finished bed casting confirmed the target microstructure: predominantly Type A graphite (size 4-5) uniformly distributed in a matrix of over 95% pearlite. This consistency between test bar and casting本体 is a hallmark of well-controlled iron and low section sensitivity.

A critical quality check for machine tool castings is hardness uniformity across long guideways. Measurements taken at three points on each of the four guideways (each ~1500 mm long) showed a maximum variation of less than 10 HBW, confirming exceptional homogeneity.

The final and most significant validation was the measurement of as-cast residual stress on the bed itself. Using the blind-hole drilling method at key locations on the guideways, the measured stresses were all well below the stringent targets of 50 MPa tensile and 98 MPa compressive. This low level of locked-in stress is the ultimate guarantee that this machine tool casting will maintain its dimensional stability throughout its service life.

Conclusions and Future Outlook

The production practice conclusively demonstrates that the high Carbon Equivalent, high Silicon-to-Carbon ratio gray iron, modified with Sn, Cr, and N, is a superior material for high-performance machine tool castings. The key outcomes are:

- The material consistently meets and exceeds standard HT300 requirements while providing an elastic modulus above 130 GPa, a critical factor for machine tool stiffness.

- It exhibits low shrinkage tendency, minimal section sensitivity, and excellent hardness uniformity across large castings, ensuring consistent machinability and performance.

- Most importantly, it results in significantly lower as-cast residual stresses, directly addressing the root cause of long-term dimensional instability in precision machine tool castings.

- The metallurgical quality indices (RG, HG, Qi) confirm a robust and well-inoculated iron with a favorable balance of strength and castability.

The shift from a low-CE paradigm to a high-CE, high-Si/C paradigm represents a fundamental advancement in the metallurgy of gray iron for structural applications. It moves the focus from merely achieving a tensile strength on a test bar to engineering the entire casting process for inherent stability. For manufacturers of precision machine tool castings, this approach provides a clear path to closing the quality gap with international leaders. The technology is now in the phase of extended field validation with machine tool builders. Continuous collaboration with end-users, research institutions, and industry experts is essential to fully document its long-term performance benefits and to further refine the alloying and processing guidelines for the next generation of even more demanding machine tool castings.