In the pursuit of manufacturing excellence, the production of high-quality machine tool castings such as beds, columns, and tables is paramount. These components form the foundational structure of precision machinery, demanding exceptional mechanical properties, dimensional stability, and damping capacity. Gray iron, particularly grades with a high carbon equivalent (CE), has long been favored for these applications due to its excellent castability, good machinability, and inherent vibration damping characteristics. However, the traditional production of high-strength gray iron often involves lower CE to achieve the desired tensile strength, which can increase the risk of casting defects, residual stresses, and reduced manufacturability. This research focuses on developing and applying a short-flow production process specifically for high-carbon-equivalent gray iron to manufacture high-performance machine tool castings, aiming to unify superior mechanical properties with excellent casting and machining performance.

The core challenge lies in overcoming the typical trade-off: high CE improves fluidity and reduces shrinkage tendency and stress, but traditionally it is associated with lower strength and a higher risk of ferrite formation, leading to softer material. Our work demonstrates that through a carefully integrated process encompassing innovative melting, precise metallurgical control, and optimized foundry practices, it is possible to produce machine tool castings with a CE above 3.8% that meet or exceed the mechanical requirements of grade HT300 (or GG25/GG30 equivalent), while exhibiting low residual stress and outstanding machinability. The short-flow aspect emphasizes efficiency, utilizing direct iron melt from a blast furnace coupled with an intermediate treatment and final adjustment in a medium-frequency induction furnace, reducing energy consumption and process steps compared to fully scrap-based melting.

Characteristics of High Carbon Equivalent Gray Iron for Machine Tool Castings

The specification “high carbon equivalent” typically refers to gray iron with a CE value greater than 3.85%. The carbon equivalent is calculated using the formula:

$$CE = C + \frac{1}{3}(Si + P)$$

For machine tool castings, a high CE offers distinct advantages:

Enhanced Castability: The higher carbon and silicon content significantly improves the fluidity of the molten iron. This allows the metal to fill complex and thin-walled sections of intricate sand molds more completely, minimizing mistruns and cold shuts, which are critical for large, bulky machine tool castings.

Reduced Shrinkage and Lower Stress: During solidification, the precipitation of graphite expands. This graphite expansion can compensate for the shrinkage of the iron matrix, thereby reducing internal micro-shrinkage porosity and the overall tendency for shrinkage cavity formation. This inherent characteristic also contributes to lower residual stresses in the final casting, a vital factor for the dimensional stability of precision machine tool castings.

Improved Machinability: Generally, higher CE promotes the formation of larger, well-distributed graphite flakes and a softer matrix, leading to better chip formation and longer tool life during machining operations.

The traditional limitation has been that these benefits often come at the expense of tensile strength and hardness. The goal of our process is to decouple this relationship, retaining the benefits of high CE while achieving the required strength through controlled solidification and targeted alloying.

The Short-Flow Production Process for High-Performance Machine Tool Castings

Our production trial centered on a large horizontal machining center bed casting, with approximate dimensions of 4900 mm x 2900 mm x 1490 mm, an average wall thickness of 30 mm, and a finished weight of about 12,270 kg. The target material was HT300-grade gray iron. The key pillars of our optimized short-flow process are detailed below.

1. Material Selection and Charge Composition

The charge composition is designed for consistency, purity, and cost-effectiveness within the short-flow model.

| Material | Percentage (%) | Key Requirement/Role |

|---|---|---|

| Blast Furnace Hot Metal | 45 | Pre-treated (desulfurized) and superheated; provides consistent base carbon and silicon. |

| Steel Scrap | 30 | Clean, low-alloy scrap to adjust final chemistry and provide nucleation sites. |

| Returns (Internal) | 20 | Carefully controlled to maintain chemical consistency. |

| Alloy Additions | 5 | Includes FeSi, FeMn, Cr, Sn, Nitrogen carrier (e.g., Nitrided Mn). |

2. Melting and Metallurgical Control

This is the cornerstone of achieving high performance with high CE. Melting was conducted in a medium-frequency coreless induction furnace. The target chemical composition and the achieved results are summarized in the following table:

| Element/Parameter | Target | Base Iron (Pre-inoculation) | Final Iron (Post-inoculation) |

|---|---|---|---|

| Carbon (C), % | 3.00 – 3.05 | 3.04 | 3.02 |

| Silicon (Si), % | 2.40 – 2.50 | 1.07 | 2.44 |

| Manganese (Mn), % | 0.80 – 0.90 | 0.51 | 0.86 |

| Phosphorus (P), % | < 0.04 | 0.023 | 0.026 |

| Sulfur (S), % | 0.04 – 0.08 | 0.029 | 0.051 |

| Chromium (Cr), % | 0.10 – 0.20 | 0.094 | 0.150 |

| Tin (Sn), % | 0.04 – 0.06 | 0.0076 | 0.047 |

| Nitrogen (N), ppm | 90 – 110 | 33 | 119 |

| Carbon Equivalent (CE), % | 3.80 – 3.85 | 3.41 | 3.84 |

| Silicon-to-Carbon Ratio (Si/C) | > 0.75 | 0.35 | 0.81 |

Key Metallurgical Strategies:

a) High Si/C Ratio: Maintaining a Si/C ratio above 0.75 at a high CE level promotes a fully pearlitic matrix by shifting the eutectic point and reducing the carbon saturation level. This is counter-intuitive to conventional wisdom where high Si promotes ferrite. The synergy with other elements prevents this.

b) Microalloying with N and Sn: This is the critical innovation. Nitrogen (added via nitrided manganese) and Tin are potent pearlite stabilizers. Nitrogen, in solution, enhances pearlite formation and refines the graphite structure, significantly increasing tensile strength without proportionally increasing hardness. Tin is a powerful pearlite promoter that segregates at the graphite/austenite interface, preventing ferrite formation. The combined effect allows for the high Si/C ratio without the expected increase in ferrite content.

c) Inoculation Practice: A multi-stage inoculation strategy was employed to ensure a fine, uniform distribution of Type A graphite:

- Pre-inoculation: 0.1% fine silicon carbide (SiC, 0.2-1 mm) added to the molten metal surface in the furnace. SiC acts as a potent nucleating agent for graphite.

- Stream Inoculation: 0.4% Si-Ba-Ca inoculant added during tapping from the furnace to the pouring ladle.

- Late Inoculation: 0.1% FeSi75 (0.2-0.7 mm) added in the pouring stream during casting. This ensures active nucleation sites are present just before solidification.

d) Temperature Control: The superheating temperature was maintained between 1650-1720°C for the hot metal treatment. The final pouring temperature was tightly controlled between 1380-1410°C to ensure optimal fluidity and feeding while minimizing gas absorption and dross formation.

3. Molding and Core Making

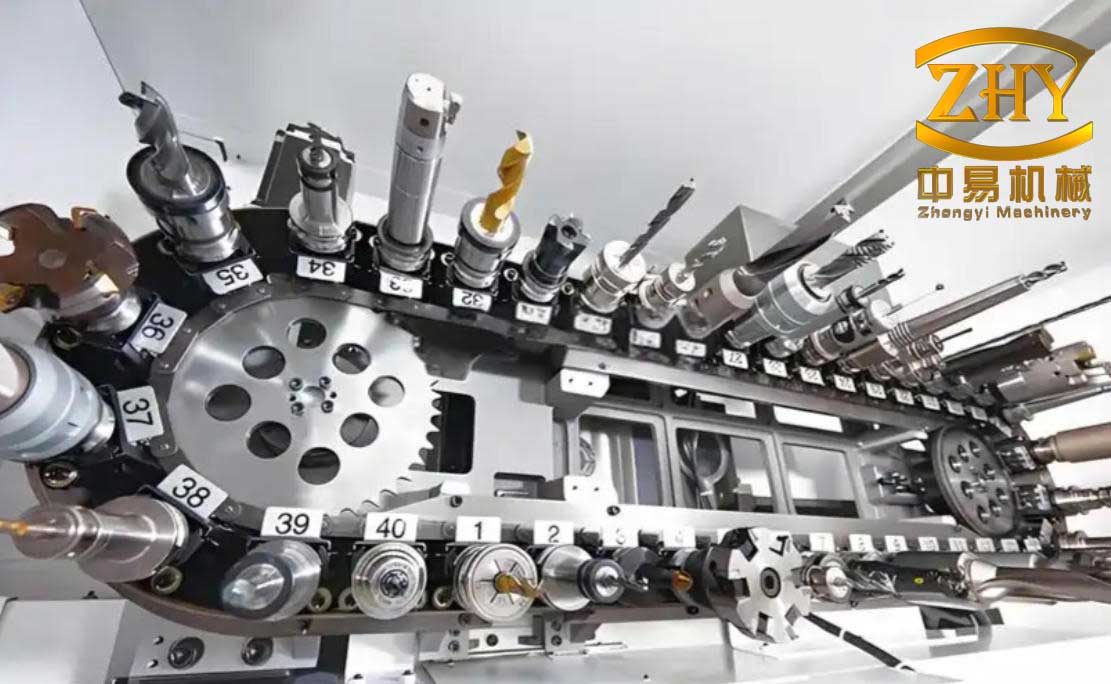

For the complex geometry and dimensional accuracy required for large machine tool castings, we employed a furan resin sand system combined with 3D sand printing technology for core making.

- 3D Printed Sand Cores: This technology allowed for the precise and rapid manufacture of complex internal cavities and water channels, eliminating the need for traditional core boxes and reducing lead time. It ensured excellent dimensional reproducibility and surface finish.

- Process Control: Key parameters for the furan resin sand were rigorously monitored: resin addition (1.0-1.1%), catalyst ratio (28-35% based on resin), tensile strength (>0.4 MPa), and mold hardness (70-90). A proprietary refractory coating with a viscosity of 38°Bé was uniformly applied to all mold and core surfaces to prevent metal penetration and improve casting surface finish.

4. Gating, Pouring, and Solidification

A pressurized gating system was designed with a choke at the base of the sprue to ensure rapid and turbulent-free filling. The cross-sectional area ratio was designed as: ΣAsprue : ΣArunner : ΣAingate = 1.2 : 1 : 0.9. The pouring time for the ~12-ton casting was controlled between 60-90 seconds. Controlled cooling was emphasized to prevent thermal stresses and cracking. The molds were allowed to cool in a regulated environment before shakeout.

5. Post-Casting Operations

After shakeout, the castings underwent standard cleaning (shot blasting, grinding). A stress-relief annealing was performed to further stabilize the dimensions of the machine tool castings. Finally, the castings were subjected to rigorous inspection including visual examination, dimensional checks, and mechanical testing.

Mechanical Properties and Metallurgical Quality Assessment

The success of the process is validated through the comprehensive evaluation of the produced machine tool castings.

1. Mechanical and Physical Properties

Separately cast test bars (30 mm diameter) were poured from the same ladle as the production casting. The results were as follows:

- Tensile Strength (Rm): 310.9 MPa (meeting HT300 requirement).

- Elastic Modulus: 124 GPa (indicating good stiffness).

- Hardness (Brinell, on casting): An average of 207 HBW measured at multiple locations on the actual bed casting, with a range of 201-216 HBW.

- Residual Stress: Measurements taken at 12 points on the un-heat-treated casting showed a range of compressive and tensile stresses, with a majority of points exhibiting relatively low stress levels (e.g., -29 to -89 MPa in compression, 4 to 25 MPa in tension), confirming the low-stress design goal.

2. Metallographic Structure

Microstructural analysis of the test bar revealed an excellent graphite formation and matrix structure:

- Graphite: >96% Type A (randomly oriented flake), size grade 4 (as per ASTM A247). This is ideal for damping capacity and thermal conductivity.

- Matrix: >98% fine pearlite. The combination of high Si/C, N, and Sn successfully suppressed the formation of free ferrite, resulting in a strong, wear-resistant matrix.

This structure directly explains the achieved mechanical properties.

3. Quantitative Metallurgical Quality Indices

Several indices are used to holistically judge the quality of gray iron, balancing strength, castability, and machinability. Our results are calculated and compared against desired benchmarks.

a) Eutectic Saturation (Sc): Indicates the relative position of the composition to the eutectic point. Higher Sc favors better castability and lower stress.

$$S_c = \frac{C}{4.26 – \frac{1}{3}(Si + P)} = \frac{3.02}{4.26 – \frac{1}{3}(2.44 + 0.026)} = 0.88$$

Result: 0.88 (Target: 0.75-1.0). This confirms the high-CE, highly castable nature of the iron.

b) Relative Strength (RG, Maturity Degree): Compares the actual strength to the “normal” strength expected for that eutectic saturation.

$$R_G = \frac{R_m}{1000 – 800 \cdot S_c} = \frac{310.9}{1000 – 800 \times 0.88} = 1.05$$

Result: 1.05 (Target: >1.0). A value >1.0 indicates that the achieved tensile strength is higher than the norm for that CE level, signifying excellent metallurgical control.

c) Relative Hardness (RH, Hardening Degree): Compares the actual hardness to the “normal” hardness for that eutectic saturation.

$$R_H = \frac{HBW}{530 – 344 \cdot S_c} = \frac{207}{530 – 344 \times 0.88} = 0.91$$

Result: 0.91 (Target: <1.0). A value <1.0 is highly desirable, indicating that the hardness is lower than typically expected for the achieved strength level. This is key for machinability.

d) Quality Factor (QI): The ratio of Relative Strength to Relative Hardness. It is a comprehensive index of the “quality” of the iron.

$$Q_I = \frac{R_G}{R_H} = \frac{1.05}{0.91} = 1.19$$

Result: 1.19 (Target: >1.0). This excellent value signifies a superior combination of high strength and relatively low hardness.

e) Machinability Coefficient (m): A direct indicator of expected machining performance, used in German standards (GG grades).

$$m = \frac{R_m}{HBW} = \frac{310.9}{207} = 1.50$$

Result: 1.50. This places our material at the top end of the machinability range for GG30/HT300 grade iron (typical m=1.15-1.50), confirming exceptional machinability.

| Metallurgical Quality Index | Symbol | Calculated Value | Target/ Benchmark | Significance for Machine Tool Castings |

|---|---|---|---|---|

| Eutectic Saturation | Sc | 0.88 | 0.75-1.00 | High castability, low shrinkage & stress tendency. |

| Relative Strength (Maturity) | RG | 1.05 | > 1.0 | Strength exceeds norm for composition; efficient use of CE. |

| Relative Hardness | RH | 0.91 | < 1.0 | Hardness is lower than norm for strength; excellent for machining. |

| Quality Factor | QI | 1.19 | > 1.0 | Superior overall metallurgical quality. |

| Machinability Coefficient | m | 1.50 | ~1.15-1.50 (for GG30) | Outstanding predicted machining performance. |

Conclusion and Outlook

This research successfully demonstrates the industrial application of a short-flow, high-carbon-equivalent production process for manufacturing high-performance gray iron machine tool castings. The key outcomes are:

- It is feasible to produce machine tool castings with a carbon equivalent of 3.84% and a high silicon-to-carbon ratio of 0.81 that meet the tensile strength requirements of HT300/GG30 grade.

- The synergistic use of microalloying elements, particularly Nitrogen and Tin, in conjunction with high Si/C ratio, is crucial for stabilizing a fully pearlitic matrix (>98%) and achieving high strength without the associated high hardness or ferrite formation.

- The metallurgical quality indices (Sc=0.88, RG=1.05, RH=0.91, QI=1.19, m=1.50) collectively prove that the produced iron offers an exceptional balance of castability, strength, low stress, and superb machinability—all critical for premium machine tool castings.

- The integrated process, combining treated blast furnace hot metal, precise inoculation, 3D sand printing, and controlled pouring, provides a reliable and efficient short-flow manufacturing route.

The future direction for such high-performance machine tool castings lies in further refining the control of nitrogen and other trace elements, exploring the use of advanced inoculants, and integrating real-time process monitoring and data analytics to achieve even greater consistency. Furthermore, extending this metallurgical approach to even higher strength grades (e.g., HT350) while maintaining high CE and machinability remains an exciting challenge. The demonstrated process marks a significant step towards manufacturing more dimensionally stable, durable, and cost-effective foundation components for the machine tool industry, contributing directly to the advancement of precision manufacturing.