In recent years, with the development of military products toward lightweight, rapid deployment, and cost-effectiveness, high-strength, high-toughness aluminum alloy shell castings have been widely used in aerospace applications. These castings, typically made from ZL114A or ZL205A alloys, are produced as integral components with stringent requirements for internal quality and mechanical properties. The manufacturing of such shell castings presents significant challenges, and conventional gravity casting often falls short in producing合格 parts with consistent quality. Even when possible, yield rates are low. To achieve reliable and high-quality shell castings, the low-pressure casting process has proven to be an effective method. In this article, I will discuss the concept of low-pressure casting, its advantages over gravity casting, and the detailed design of gating systems and selection of process parameters for producing优质 aluminum alloy shell castings. Throughout, I will emphasize the critical role of this process in enhancing the integrity of shell castings.

Low-pressure casting is a method介于 gravity casting and pressure die-casting. It involves using a relatively low gas pressure to force molten metal into a mold, where it solidifies under pressure to form a casting. The process begins by placing the mold above a sealed crucible containing the molten metal. Dry compressed air or inert gas is introduced into the crucible, applying pressure on the metal surface. This pressure causes the metal to rise through a stalk tube and fill the mold cavity via the gating system. Once the cavity is full, the pressure is increased and maintained until the casting solidifies completely. Subsequently, the pressure is released, allowing any unsolidified metal in the stalk and gating system to fall back into the crucible. This completes one cycle of low-pressure casting, ideal for producing complex shell castings with minimal defects.

Compared to gravity casting, where molten metal is poured from a ladle into the mold relying solely on gravitational force, low-pressure casting offers several key advantages for shell castings. These benefits are summarized in the table below:

| Aspect | Gravity Casting | Low-Pressure Casting |

|---|---|---|

| Filling Mechanism | Top-pouring, turbulent flow | Bottom-filling, laminar flow |

| Metal Oxidation and Gas Entrapment | High due to splashing and agitation | Low due to controlled filling |

| Casting Defects | Prone to inclusions, porosity, slag | Reduced defects, improved density |

| Mechanical Properties | Standard levels | Enhanced by 10% or more |

| Fluidity for Thin Sections | Limited, may cause cold shuts | Improved, allows complex geometries |

| Yield and Material Usage | Lower due to extensive gating/risers | Higher, with simplified gating |

| Automation Potential | Manual, labor-intensive | Easily automated, consistent |

These advantages make low-pressure casting particularly suitable for producing high-integrity shell castings, where internal soundness and mechanical performance are critical. The process minimizes turbulence, reducing gas entrapment and oxidation that often plague gravity-cast shell castings.

For aluminum alloy shell castings, which are typically cylindrical or conical in shape, the gating system design is crucial to ensure uniform heat distribution,平稳 filling, and effective feeding. A slit-type gating system is commonly employed. This system promotes directional solidification, where the casting solidifies first, followed by the slit gates, vertical risers, horizontal runners, and finally the stalk tube. This sequence requires that cross-sectional areas increase progressively from the casting to the stalk, ensuring adequate feeding to prevent shrinkage porosity. The key dimensions for the slit and vertical riser are determined based on the wall thickness of the shell castings. The relationships can be expressed with formulas and summarized in a table.

The slit width \(a\) is calculated as:

– For wall thickness \(\delta \leq 10\, \text{mm}\): \(a = (1 \sim 1.5) \delta\)

– For wall thickness \(\delta > 10\, \text{mm}\): \(a = (0.8 \sim 1.0) \delta\)

The slit length \(b\) typically ranges from 20 to 40 mm. The vertical riser diameter \(D\) is given by: \(D = (4 \sim 6) a\). The number of vertical risers \(n\) depends on the outer circumference of the shell casting \(p\): \(n = 0.024 \frac{p}{a}\). These parameters ensure that the risers and gates solidify slower than the casting wall, providing effective feeding for dense shell castings.

| Parameter | Symbol | Formula or Range | Remarks for Shell Castings |

|---|---|---|---|

| Slit Width | \(a\) | \(a = k \delta\) where \(k = 1-1.5\) for \(\delta \leq 10\, \text{mm}\), \(k = 0.8-1.0\) for \(\delta > 10\, \text{mm}\) | Ensures adequate feeding based on wall thickness |

| Slit Length | \(b\) | 20–40 mm | Promotes平稳 metal flow |

| Vertical Riser Diameter | \(D\) | \(D = (4 \sim 6) a\) | Provides sufficient thermal mass for feeding |

| Number of Risers | \(n\) | \(n = 0.024 \frac{p}{a}\) | Distributes feeding points around the shell casting |

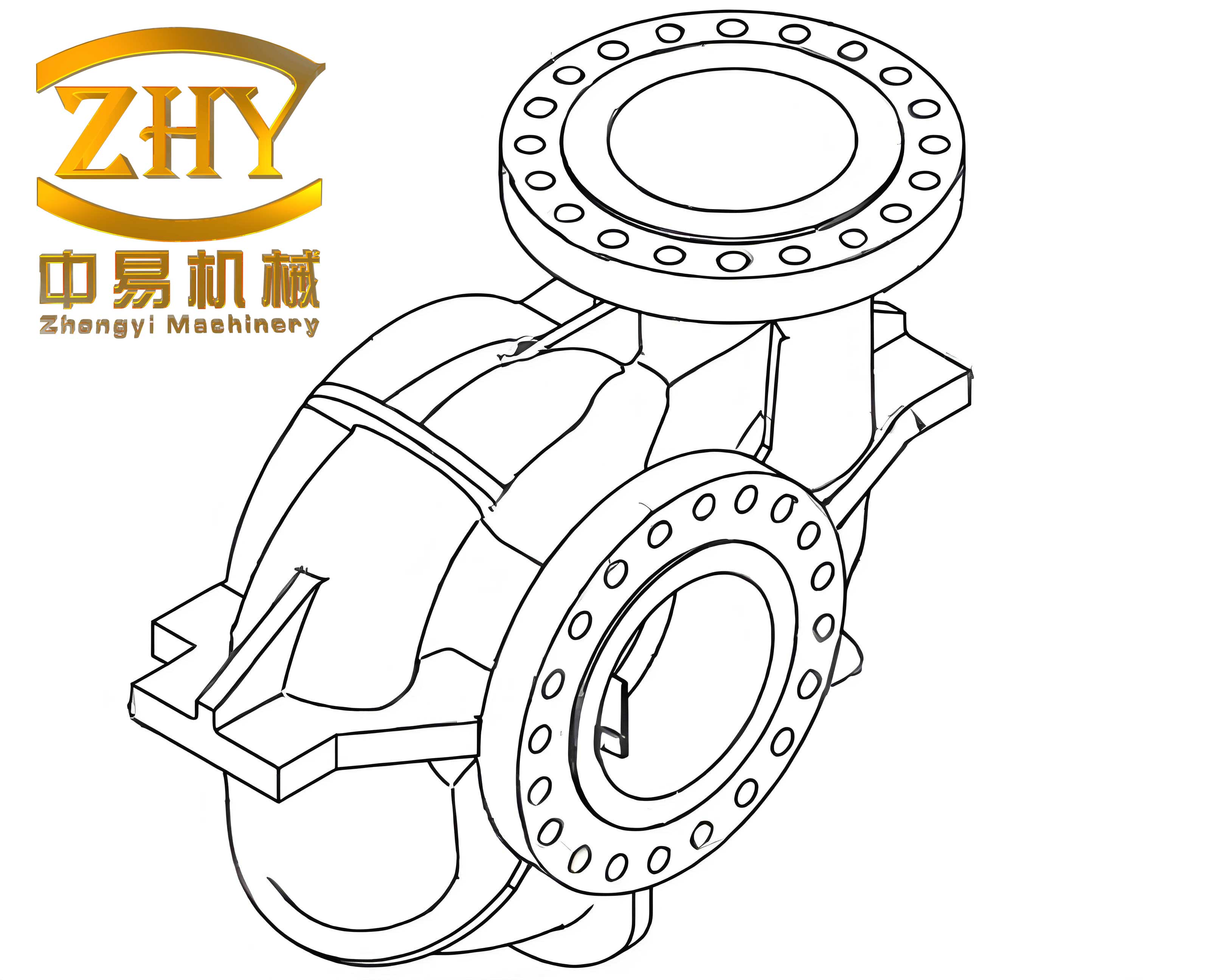

To visualize a typical gating system for shell castings, consider the following illustration, which shows the arrangement of slit gates and risers around a cylindrical shell casting. This design is critical for achieving high-quality shell castings with minimal shrinkage defects.

The low-pressure casting process involves several stages:升液 (metal rise),充型 (mold filling),增压结晶 (pressure increase and solidification),保压凝固 (pressure holding), and卸压冷却 (pressure release and cooling). Each stage requires precise control of parameters to optimize the quality of shell castings. The pressure-time profile can be represented as a curve with distinct phases, as described below.

In the metal rise stage, the goal is to raise the molten metal平稳ly from the crucible to the mold gate. The rise velocity \(V_1\) is typically set around 50 mm/s, corresponding to a pressure ramp rate of \(V_{p1} = 0.0014\, \text{MPa/s}\). The rise pressure \(P_1\) is calculated as:

$$P_1 = H \gamma \mu$$

where \(H\) is the distance from the mold gate to the metal surface in the crucible (in meters), \(\gamma\) is the metal density (approximately \(2400\, \text{kg/m}^3\) for aluminum alloys), and \(\mu\) is a resistance factor ranging from 1.0 to 1.5. The rise time \(t_1\) is:

$$t_1 = \frac{P_1}{V_{p1}}$$

This controlled rise minimizes turbulence, essential for defect-free shell castings.

During mold filling, the metal enters the cavity until full. The filling velocity \(V_2\) depends on the wall thickness of the shell casting. For thick-walled shell castings, a velocity similar to the rise stage (50 mm/s or \(V_{p2} = 0.0014\, \text{MPa/s}\)) can be used to allow gas escape. For thin-walled shell castings, a higher velocity (50–80 mm/s or \(V_{p2} = 0.0014–0.0022\, \text{MPa/s}\)) is needed to prevent cold shuts and ensure complete filling. The filling pressure \(P_2\) is:

$$P_2 = H’ \gamma \mu$$

where \(H’\) is the height from the metal surface in the crucible after filling to the highest point of the mold. The filling time \(t_2\) is:

$$t_2 = \frac{P_2 – P_1}{V_{p2}}$$

Proper filling control is vital for achieving precise geometries in shell castings.

After filling, the pressure is increased rapidly to enhance feeding during solidification. The增压 rate \(V_{p3}\) is about \(0.01\, \text{MPa/s}\). The增压 pressure \(P_3\) is typically \(0.02–0.04\, \text{MPa}\) above \(P_2\),足够 to promote dense microstructure without causing mold wall failure or mechanical penetration. The holding time \(t_3\) depends on factors like alloy type, pouring temperature, and mold conditions. For shell castings, it can be estimated based on weight or experience. The pressure holding ensures that shrinkage porosity is minimized, yielding robust shell castings with improved mechanical properties.

Finally, in the pressure release stage, the pressure is卸除 over 5–30 seconds, allowing residual metal to return to the crucible. The casting is then cooled in the mold for 2–24 hours before extraction, depending on size and alloy. This controlled cooling prevents distortion and residual stresses in the shell castings.

To summarize the process parameters, I present a comprehensive table below. This table encapsulates the key variables for each stage, tailored for aluminum alloy shell castings.

| Stage | Key Parameters | Typical Values or Formulas | Impact on Shell Castings |

|---|---|---|---|

| Metal Rise | Rise velocity \(V_1\), Pressure \(P_1\), Time \(t_1\) | \(V_1 = 50\, \text{mm/s}\), \(P_1 = H \gamma \mu\), \(t_1 = P_1 / 0.0014\) | Ensures平稳 start, reduces gas entrapment |

| Mold Filling | Filling velocity \(V_2\), Pressure \(P_2\), Time \(t_2\) | \(V_2 = 50–80\, \text{mm/s}\), \(P_2 = H’ \gamma \mu\), \(t_2 = (P_2 – P_1) / V_{p2}\) | Controls filling quality, prevents defects |

| Pressure Increase | 增压 rate \(V_{p3}\), Pressure \(P_3\) | \(V_{p3} = 0.01\, \text{MPa/s}\), \(P_3 = P_2 + (0.02–0.04)\, \text{MPa}\) | Enhances feeding, reduces porosity |

| Pressure Holding | Holding time \(t_3\) | Empirical, based on casting weight | Ensures complete solidification |

| Pressure Release | Release time \(t_4\) | 5–30 seconds | Prevents backflow issues |

| Cooling | Cooling time \(t_5\) | 2–24 hours | Avoids distortion, stabilizes structure |

In addition to these parameters, the choice of alloy plays a significant role. ZL114A and ZL205A alloys are commonly used for shell castings due to their high strength and toughness. Their properties can be further enhanced by low-pressure casting. For instance, the mechanical性能 improvement can be quantified. The ultimate tensile strength \(\sigma_u\) and yield strength \(\sigma_y\) often increase by a factor related to the applied pressure and solidification rate. A simplified model for the density improvement \(\Delta \rho\) in shell castings due to pressure \(P\) during solidification is:

$$\Delta \rho \propto \frac{P}{\eta} \cdot \frac{1}{T_s – T_l}$$

where \(\eta\) is the metal viscosity, \(T_s\) is the solidus temperature, and \(T_l\) is the liquidus temperature. This underscores how low-pressure casting boosts the integrity of shell castings.

Quality control measures for shell castings include non-destructive testing like X-ray radiography and fluorescent inspection, as well as mechanical testing of coupons cut from the castings. The consistent results from these tests validate the effectiveness of the low-pressure process for producing reliable shell castings.

In practice, we have successfully manufactured various shell castings using this process, ranging from small cylindrical housings to large conical structures. All castings met stringent specifications for chemical composition, mechanical properties (tested via separate coupons, attached coupons, and sectioned samples), and non-destructive evaluation. They have performed well in ground and flight tests, demonstrating the robustness of low-pressure casting for aerospace shell castings.

To further optimize the process, we can use computational simulations to model fluid flow and solidification. For example, the filling velocity profile can be analyzed using the Navier-Stokes equations for incompressible flow:

$$\rho \left( \frac{\partial \mathbf{v}}{\partial t} + \mathbf{v} \cdot \nabla \mathbf{v} \right) = -\nabla P + \mu \nabla^2 \mathbf{v} + \mathbf{f}$$

where \(\mathbf{v}\) is the velocity vector, \(P\) is pressure, \(\rho\) is density, \(\mu\) is dynamic viscosity, and \(\mathbf{f}\) represents body forces. Applying this to the gating system of shell castings helps predict and minimize turbulence.

Moreover, the solidification time \(t_s\) for a shell casting can be estimated using Chvorinov’s rule:

$$t_s = C \left( \frac{V}{A} \right)^n$$

where \(V\) is volume, \(A\) is surface area, \(C\) is a constant dependent on mold material and alloy, and \(n\) is an exponent typically around 2. For cylindrical shell castings with wall thickness \(\delta\), the modulus \(V/A\) approximates \(\delta/2\) for thin walls, simplifying planning of holding times.

In conclusion, the low-pressure casting process is indispensable for producing high-quality aluminum alloy shell castings. Its ability to provide controlled filling, pressure-assisted solidification, and high yield makes it superior to gravity casting. By carefully designing slit-type gating systems and selecting appropriate process parameters—supported by formulas and tables—we can consistently achieve shell castings with excellent internal quality and mechanical performance. As aerospace demands evolve, this process will continue to be a cornerstone for manufacturing lightweight, reliable shell castings. Future work may explore advanced alloys and real-time monitoring to further enhance the production of shell castings.

Throughout this discussion, the term “shell castings” has been emphasized to highlight the specific application. The principles outlined here are broadly applicable, but they are particularly critical for shell castings where structural integrity is paramount. By leveraging low-pressure casting, we ensure that every shell casting meets the highest standards, contributing to safer and more efficient aerospace systems.