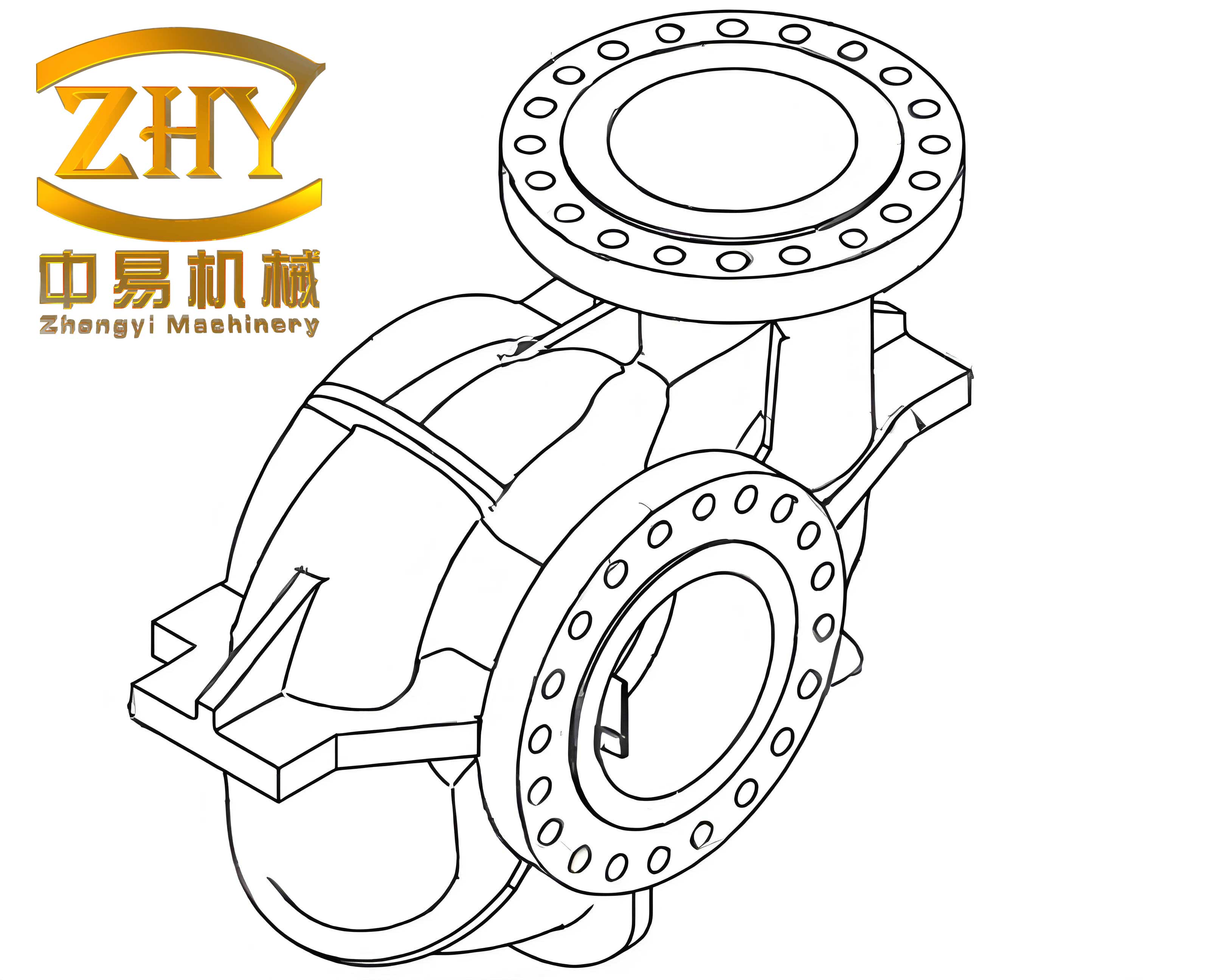

In the competitive landscape of foundry operations, particularly for shell castings such as gearbox casings, rising costs of raw materials like pig iron have driven the need for innovative and cost-effective melting practices. As a foundry engineer involved in the production of shell castings, I have explored the use of medium frequency furnaces to melt scrap iron, specifically machining chips, to manufacture components like transmission housings. This approach not only reduces production costs by approximately 40% but also maintains high mechanical properties, with tensile strengths exceeding 240 MPa. In this article, I will detail our journey, from furnace selection to process optimization, emphasizing how this method enhances the sustainability and efficiency of shell castings production.

The production of shell castings, which often include complex geometries like gearbox casings, requires precise control over melting and casting parameters to ensure dimensional accuracy and structural integrity. Traditional methods using cupola furnaces faced challenges with temperature stability and high coke-to-iron ratios, leading to inconsistent quality in shell castings. After evaluating various options, we transitioned to a 1.5-ton medium frequency furnace, which offers superior temperature control and the ability to handle high percentages of scrap iron. This shift has revolutionized our shell castings production, allowing us to utilize up to 90% iron屑 in the charge while achieving the desired microstructure and performance.

One critical aspect of shell castings is the chemical composition, which directly influences the mechanical properties. For gearbox casings made of HT250-grade iron, we control the composition within the following ranges:

| Element | Target Range (wt%) | Importance for Shell Castings |

|---|---|---|

| Carbon (C) | 3.2% – 3.6% | Enhances fluidity and reduces shrinkage in thin-walled shell castings. |

| Silicon (Si) | 1.6% – 2.0% | Promotes graphite formation, improving machinability of shell castings. |

| Manganese (Mn) | 0.7% – 1.0% | Increases strength and hardness in shell castings. |

| Phosphorus (P) | < 0.15% | Minimized to prevent brittleness in shell castings. |

| Sulfur (S) | < 0.12% | Controlled to avoid hot tearing in shell castings. |

To achieve this, we use a charge mix typically composed of 60% iron屑, 20% returns (such as runners and risers from previous shell castings), and 20% pig iron. In some cases, for high-volume production of shell castings, we increase the scrap content to 90%, relying on carburizers to adjust carbon levels. The carburization process can be described by the following reaction, which is crucial for maintaining the carbon equivalent in shell castings:

$$ \text{C}_{\text{(carburizer)}} + \text{Fe} \rightarrow \text{Fe}_3\text{C} \quad \text{or} \quad \text{C}_{\text{dissolved}} \text{ in melt} $$

This ensures that the melt chemistry supports the formation of fine graphite flakes in the final shell castings. The use of scrap iron not only lowers costs but also aligns with circular economy principles, making shell castings production more environmentally friendly.

Melting temperature is another key factor for shell castings, as it affects the elimination of genetic inheritance from the charge materials. In medium frequency furnaces, we achieve a superheating temperature of 1560°C, which is higher than that possible in cupolas. This high temperature helps dissolve carbides and homogenize the melt, reducing the genetic effects that can lead to inconsistent properties in shell castings. The thermal balance during melting can be approximated by:

$$ Q_{\text{input}} = m_{\text{charge}} \cdot c_p \cdot \Delta T + Q_{\text{losses}} $$

where \( Q_{\text{input}} \) is the electrical energy input, \( m_{\text{charge}} \) is the mass of the charge, \( c_p \) is the specific heat capacity of iron, \( \Delta T \) is the temperature rise, and \( Q_{\text{losses}} \) accounts for heat losses to the environment. For shell castings, maintaining a consistent melt temperature above 1500°C ensures proper fluidity for filling thin sections.

During furnace operation, we monitor the melt using wedge tests. A triangular sample with dimensions 40 mm height, 20 mm width, and 130 mm length is poured and cooled to a dull red color before water quenching. The chill width, typically around 9 mm, indicates the carbon equivalent and helps us decide whether to proceed with pouring for shell castings. This empirical method is complemented by spectroscopic analysis for precise control, ensuring that each batch of shell castings meets specifications.

The molding process for shell castings employs green sand molds with bentonite as the binder. We use fine-grained bentonite (98% passing 200 mesh) at 6–7% addition, along with 5–6% coal dust to prevent mechanical sand adhesion and reduce subsurface gas defects. This is critical for shell castings, which often have intricate cores and require smooth surface finishes. The sand properties can be summarized as follows:

| Parameter | Value | Role in Shell Castings |

|---|---|---|

| Bentonite Content | 6–7% | Provides bond strength for mold integrity in shell castings. |

| Coal Dust Content | 5–6% | Creates a reducing atmosphere, improving surface finish of shell castings. |

| Moisture Content | 3–4% | Optimized for compactability and gas evolution in shell castings. |

| Permeability | 80–100 | Allows gases to escape during pouring of shell castings. |

Pouring practices are tailored for shell castings to avoid defects like cold shuts and slag inclusions. We maintain a pouring temperature of 1360–1380°C and use a fast, steady, and continuous pour with effective slag skimming. The filling time for shell castings can be estimated using Bernoulli’s principle adapted for fluid flow:

$$ v = \sqrt{2gh} \quad \text{and} \quad Q = A \cdot v $$

where \( v \) is the velocity of the metal stream, \( g \) is gravitational acceleration, \( h \) is the height of the sprue, \( Q \) is the flow rate, and \( A \) is the cross-sectional area of the gating system. For shell castings, a well-designed gating system ensures minimal turbulence and rapid filling.

The results from this process have been highly positive for shell castings production. Mechanical testing of specimens cast from the same melt shows tensile strengths (σ_b) between 240–249 MPa and hardness values of 210–220 HB, fully meeting the requirements for gearbox casings. Microstructural analysis reveals fine, uniformly distributed graphite flakes with rounded edges and a pearlitic matrix, which are ideal for the durability of shell castings. Daily production of shell castings, such as transmission housings, averages 300 pieces with a yield rate exceeding 95%, demonstrating the reliability of this method.

Safety monitoring in medium frequency furnaces is paramount, especially when melting scrap iron for shell castings. Iron屑 often contains oils and moisture, which can cause violent explosions if not properly managed. We implement drying procedures such as centrifugal drying, baking, or sun-drying to reduce hazards. Additionally, we address issues like bridging and skull formation in the furnace by using proper charging sequences—placing heavier materials like pig iron on top of scrap. The furnace system includes closed-loop cooling with temperature and flow monitoring, emergency cooling water tanks, and robust electrical protections. These measures ensure safe and continuous operation for shell castings production.

Beyond the immediate application, the use of medium frequency furnaces for shell castings offers broader benefits. Compared to cupolas or dedicated scrap melters, medium frequency furnaces provide better environmental control, with lower emissions and energy consumption. The cost savings are significant; for shell castings, we estimate a reduction of about 600 USD per ton of castings produced. This aligns with industry trends toward sustainable manufacturing, where shell castings play a key role in automotive and machinery sectors.

To further optimize shell castings production, we have developed predictive models for microstructure evolution. The cooling rate in shell castings influences the graphite morphology, which can be described by the following relationship derived from solidification theory:

$$ \lambda = k \cdot (G \cdot v)^{-n} $$

where \( \lambda \) is the graphite flake spacing, \( k \) and \( n \) are material constants, \( G \) is the temperature gradient, and \( v \) is the growth velocity. For shell castings, controlling cooling through mold design ensures the desired fine graphite structure. Additionally, we use statistical process control to monitor variations in shell castings, tracking parameters like chemistry and temperature over time.

In conclusion, the adoption of medium frequency furnaces for melting scrap iron has transformed our shell castings production. It enables high-quality output with consistent properties, while dramatically lowering costs. The success with gearbox casings can be extended to other shell castings, such as pump housings or valve bodies, by adjusting the charge makeup and process parameters. As foundries worldwide face pressure to reduce costs and environmental impact, this approach offers a viable path forward for shell castings. Future work will focus on integrating real-time sensors and AI-driven control systems to further enhance the efficiency and quality of shell castings, ensuring they meet the evolving demands of modern engineering applications.

Throughout this article, I have emphasized the importance of shell castings in industrial manufacturing and how innovative melting techniques can unlock their full potential. By leveraging scrap materials and advanced furnace technology, we not only improve profitability but also contribute to a more sustainable future for the casting industry. Shell castings, with their complex shapes and critical functions, will continue to benefit from such advancements, driving progress in sectors ranging from automotive to aerospace.