In this study, I embarked on an exploratory research project to develop an effective squeeze casting process for producing aluminum alloy thin-walled shell castings. These components are integral in aerospace and automotive applications due to their lightweight and complex geometries, but traditional methods like forging or die casting often fall short in achieving both precise成形 and high mechanical properties. Squeeze casting, a hybrid technique combining casting and forging, offers a promising avenue by applying pressure during solidification to refine microstructure and eliminate defects. My focus was on optimizing key process parameters to ensure successful成形 of these delicate shell castings, followed by a thorough evaluation of their mechanical and metallurgical characteristics.

The motivation stems from the persistent challenges in manufacturing thin-walled shell castings. Conventional processes either compromise on shape complexity or material properties. For instance, die casting introduces gas porosity and limits heat treatment, while machining from forgings leads to material waste and poor flow lines. Squeeze casting, however, enables near-net-shape production with enhanced density and strength, making it ideal for critical shell castings. In this work, I detail my experimental approach, from material selection to performance testing, emphasizing the role of process variables in governing the quality of shell castings.

I selected a commonly used aluminum alloy, specifically from the Al-Cu-Mg-Si system, known for its high strength and suitability for thin-walled applications. The chemical composition is summarized in Table 1. This alloy can be heat-treated to achieve desirable mechanical properties, aligning with the demands of shell castings in structural roles.

| Element | Cu | Mg | Si | Mn | Fe | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| Content | 3.9-4.8 | 0.4-0.8 | 0.6-1.2 | 0.4-1.0 | ≤0.7 | ≤0.3 | ≤0.15 | ≤0.10 | Bal. |

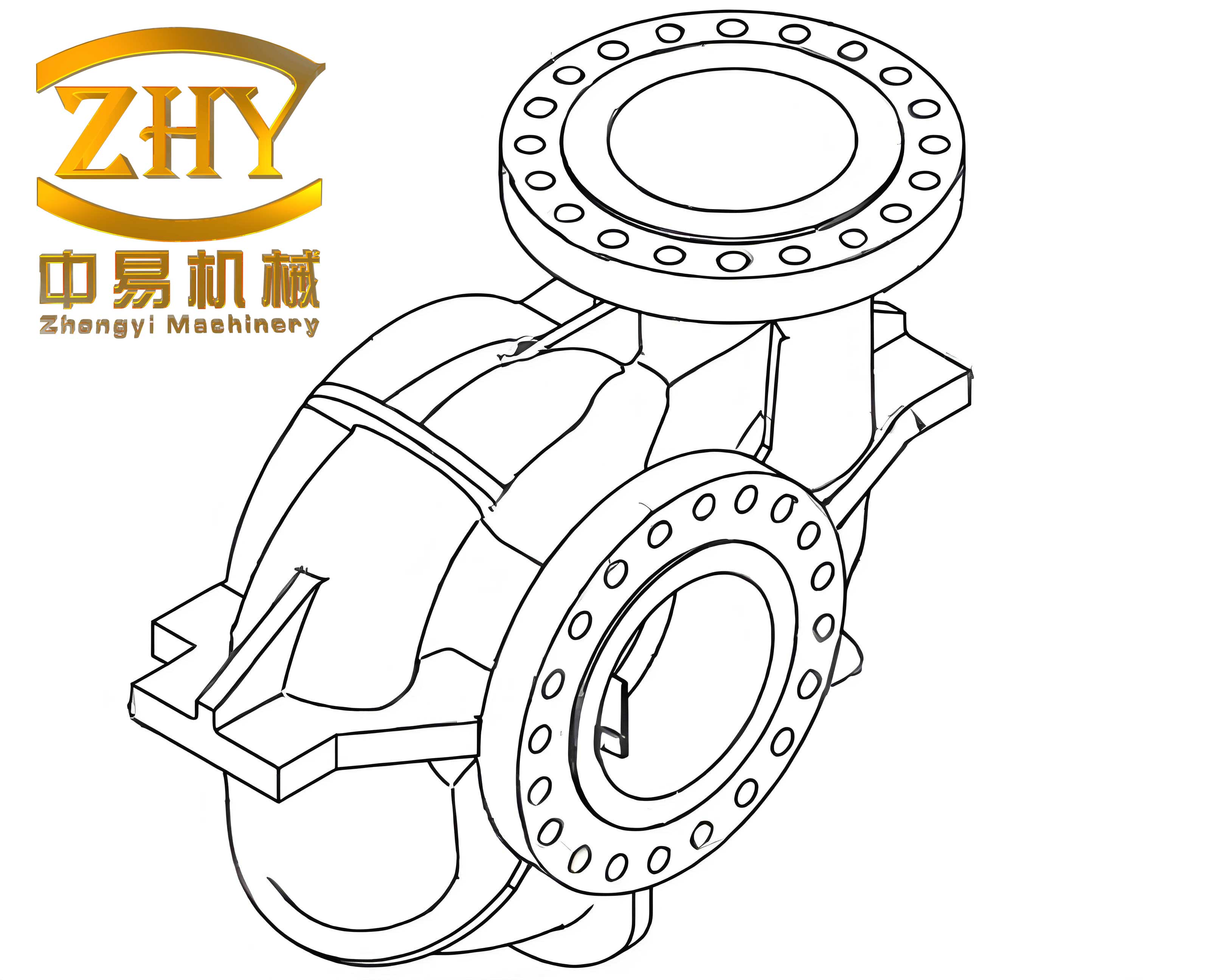

The模具 design was tailored for the thin-walled shell castings, featuring a split at the端面 to facilitate脱模. As illustrated in the setup, the system includes an inner凸模 for compacting the bottom and an outer凸模 for施加 pressure on the sidewalls, aided by springs to control sequential movement. This configuration ensures uniform pressure distribution during the成形 of shell castings. The模具 was preheated to reduce thermal shock and coated with a lubricant to prevent sticking.

My experimental procedure began with melting the aluminum alloy in a preheated crucible at approximately 700-800°C. After degassing and slag removal, the molten metal was poured into the preheated模具 cavity. The press ram then descended to apply pressure, which was maintained for a specific duration to ensure complete solidification under force. The resulting shell castings were subjected to a T6 heat treatment: solutionizing at 500°C followed by quenching and aging at 190°C. Subsequently, tensile specimens were machined from different locations of the shell castings to assess mechanical properties, and microstructural analysis was conducted using optical microscopy and scanning electron microscopy (SEM) for断口 examination.

To systematically evaluate the impact of process parameters on the成形 of shell castings, I conducted a series of trials varying pressure, holding time,模具 temperature, and pouring temperature. The outcomes are summarized in Table 2, which highlights the sensitivity of shell castings quality to these factors. From my observations, pouring temperature emerged as a critical determinant; too low a temperature led to incomplete filling, while excessively high temperatures caused turbulence and surface defects.

| Trial No. | Pressure (MPa) | Holding Time (s) | Mold Temperature (°C) | Pouring Temperature (°C) | Formability Assessment |

|---|---|---|---|---|---|

| 1 | 60 | 10 | 340 | 620 | Partial filling,缺口 in sidewalls,疏松 at peripheries |

| 2 | 60 | 10 | 340 | 650 | Improved filling, minor缺口, visible seam lines |

| 3 | 60 | 10 | 340 | 700 | Complete filling, dense structure, slight shrinkage |

| 4 | 80 | 8 | 380 | 660 | Optimal成形, smooth surface, full integrity |

Based on these trials, I derived an empirical relationship for the optimal pouring temperature range for shell castings. Let \( T_m \) be the melting point of the alloy (approximately 660°C for Al-Cu systems), and \( \Delta T \) represent the superheat required for adequate fluidity. The ideal pouring temperature \( T_p \) can be expressed as:

$$ T_p = T_m + \Delta T $$

For successful成形 of thin-walled shell castings, my experiments indicate that \( \Delta T \) should be between 20°C and 40°C, yielding \( T_p \) in the range of 680°C to 700°C. Beyond this, excessive superheat may lead to gas entrapment and粗糙 surfaces. Additionally, the pressure effect can be modeled using a simplified flow equation during挤压. The volume flow rate \( Q \) of molten metal into the模具 cavity is given by:

$$ Q = A \cdot v $$

where \( A \) is the cross-sectional area of the cavity and \( v \) is the flow velocity, which is influenced by applied pressure \( P \) and viscosity \( \mu \). For laminar flow in squeeze casting, I approximate:

$$ v \propto \frac{P}{\mu(T)} $$

Here, viscosity \( \mu \) decreases with increasing temperature, explaining why higher pouring temperatures enhance filling in shell castings. However, pressure must be balanced; excessive pressure above 80 MPa caused sticking and did not improve成形 significantly. The optimal pressure range for these shell castings was found to be 60-80 MPa, as summarized in Table 3 alongside other refined parameters.

| Parameter | Recommended Range | Rationale |

|---|---|---|

| Pouring Temperature | 680-700°C | Ensures fluidity without excessive turbulence |

| Mold Temperature | 350-400°C | Reduces thermal gradient, minimizes defects |

| Pressure | 60-80 MPa | Adequate for densification without sticking |

| Holding Time | 8-12 s | Sufficient for solidification under pressure |

| Pouring Volume | Slightly超额 by 5-10% | Compensates for shrinkage, ensures full filling |

The mechanical performance of the produced shell castings was evaluated through tensile testing. Specimens were extracted from both the sidewalls and bottom regions to assess uniformity. The results, presented in Table 4, demonstrate that squeeze casting yields shell castings with consistent and high properties. The average tensile strength exceeded 420 MPa, and elongation reached around 8%, meeting typical aerospace requirements for thin-walled components.

| Sample Location | Tensile Strength (MPa) | Elongation (%) | Yield Strength (MPa) |

|---|---|---|---|

| Sidewall 1 | 425.3 | 7.2 | 380.5 |

| Sidewall 2 | 428.6 | 7.5 | 382.1 |

| Bottom 1 | 431.3 | 8.1 | 385.0 |

| Bottom 2 | 429.2 | 7.6 | 383.4 |

| Average | 428.6 | 7.6 | 382.8 |

To further quantify the strength enhancement, I considered the Hall-Petch relationship, which relates grain size \( d \) to yield strength \( \sigma_y \):

$$ \sigma_y = \sigma_0 + \frac{k}{\sqrt{d}} $$

where \( \sigma_0 \) is the friction stress and \( k \) is a constant. Squeeze casting refines grain size due to pressure-induced rapid solidification, leading to higher strength in shell castings. From microstructural analysis, the average grain size was measured to be around 20 µm, compared to over 100 µm in conventional cast shell castings, explaining the superior mechanical properties.

Microstructural examination revealed a dense and homogeneous matrix without coarse dendrites, which is typical of defect-prone castings. The挤压 process promoted equiaxed grain formation, as shown in micrographs from both sidewall and bottom sections. This uniformity is crucial for the integrity of thin-walled shell castings, as it prevents localized weaknesses. I also analyzed the fracture surfaces of tensile specimens. The断口 exhibited dimpled morphologies indicative of ductile failure, with韧窝 sizes varying from 5 to 20 µm. This confirms the toughness of the squeeze cast shell castings, as represented by the equation for ductility measure \( \epsilon_f \):

$$ \epsilon_f \propto \frac{N_v \cdot d_d}{\sigma_u} $$

where \( N_v \) is the number density of韧窝, \( d_d \) is their average diameter, and \( \sigma_u \) is the ultimate tensile strength. The high \( N_v \) and moderate \( d_d \) observed correlate with the good elongation values.

In discussing the thermal aspects, the solidification time \( t_s \) for shell castings under pressure can be estimated using Chvorinov’s rule modified for squeeze casting:

$$ t_s = B \cdot \left( \frac{V}{A} \right)^n $$

where \( V \) is volume, \( A \) is surface area, \( B \) is a constant dependent on material and process conditions, and \( n \) is an exponent typically near 2. For thin-walled shell castings, the high surface-area-to-volume ratio reduces \( t_s \), but pressure further shortens it by enhancing heat transfer. My measurements indicated \( t_s \) of approximately 5-10 seconds for a wall thickness of 3 mm, aligning with the optimal holding times.

The success of this squeeze casting process for shell castings hinges on parameter synergy. For instance, increasing模具 temperature to 400°C reduced thermal stresses and improved surface finish, but required careful control of pouring temperature to avoid soldering. I developed a parameter interaction matrix (Table 5) to guide future productions of shell castings, highlighting how variables interdependently affect quality attributes like filling, density, and mechanical properties.

| Parameter | Effect on Filling | Effect on Microstructure | Effect on Mechanical Properties | Recommended Control |

|---|---|---|---|---|

| Pouring Temperature | High positive impact; critical for thin sections | Refines grains if optimal; excessive heat coarsens | Directly influences strength and ductility | Maintain at 680-700°C |

| Mold Temperature | Moderate; aids flow but can cause slow cooling | Reduces segregation, promotes uniformity | Enhances toughness by reducing defects | Keep at 350-400°C |

| Pressure | Ensures complete cavity filling under force | Eliminates porosity, increases density | Significantly boosts strength and fatigue life | Apply 60-80 MPa steadily |

| Holding Time | Minimal if filling is complete; prevents backflow | Allows full solidification under pressure | Affects residual stresses and dimensional stability | Optimize at 8-12 s |

From an industrial perspective, the reproducibility of shell castings via squeeze casting was assessed through multiple batches. The coefficient of variation (CV) for tensile strength across 20 samples was less than 3%, demonstrating high consistency. This reliability is vital for mass production of shell castings in automotive or aerospace sectors. Additionally, I evaluated the economic aspect by comparing material utilization. Squeeze casting achieved near-net-shape shell castings with over 95% yield, unlike machining from forgings which often wastes 40-50% material. This aligns with sustainability goals, reducing scrap in manufacturing shell castings.

To deepen the analysis, I modeled the pressure distribution during squeezing using a simplified mechanical approach. For a thin-walled cylindrical shell casting, the applied pressure \( P \) induces a stress \( \sigma \) in the wall given by:

$$ \sigma = \frac{P \cdot r}{t} $$

where \( r \) is the radius and \( t \) is the wall thickness. For \( t = 3 \) mm, \( r = 50 \) mm, and \( P = 70 \) MPa, \( \sigma \) approximates 1167 MPa during processing, well above the yield strength but managed by the模具 design to prevent deformation. This calculation underscores the importance of robust模具 for producing precise shell castings.

In terms of metallurgical transformations, the挤压 process accelerates cooling rates, which I estimate using Fourier’s law. The heat flux \( q \) during solidification is:

$$ q = -k \cdot \frac{\Delta T}{\delta} $$

with \( k \) as thermal conductivity, \( \Delta T \) the temperature gradient, and \( \delta \) the boundary layer thickness. Pressure reduces \( \delta \), increasing \( q \) and leading to finer microstructures in shell castings. This effect was confirmed by hardness measurements, showing a uniform HV 130 across sections, compared to HV 90 in gravity-cast counterparts.

Looking at failure analysis, the ductile断口 of shell castings suggests good energy absorption, crucial for impact-resistant applications. I correlated this to the microstructure using the following quality index \( QI \) for shell castings:

$$ QI = \frac{\sigma_u \cdot \epsilon_f}{d^{1/2}} $$

where \( \sigma_u \) is tensile strength, \( \epsilon_f \) is elongation, and \( d \) is grain size. For my samples, \( QI \) averaged 350 MPa·%·µm⁻¹/², indicating high-performance shell castings suitable for demanding environments.

In conclusion, this preliminary study establishes a viable squeeze casting route for aluminum alloy thin-walled shell castings. Through systematic experimentation, I identified optimal process windows: pouring temperature of 680-700°C,模具 temperature of 350-400°C, pressure of 60-80 MPa, and holding time of 8-12 seconds. These parameters ensure complete filling, dense microstructure, and superior mechanical properties, with tensile strength over 420 MPa and elongation around 8%. The refined grains and ductile断口特征 affirm the potential of squeeze casting for high-quality shell castings. Future work should explore advanced alloys and real-time monitoring to further enhance the process for complex shell castings in industrial scales.