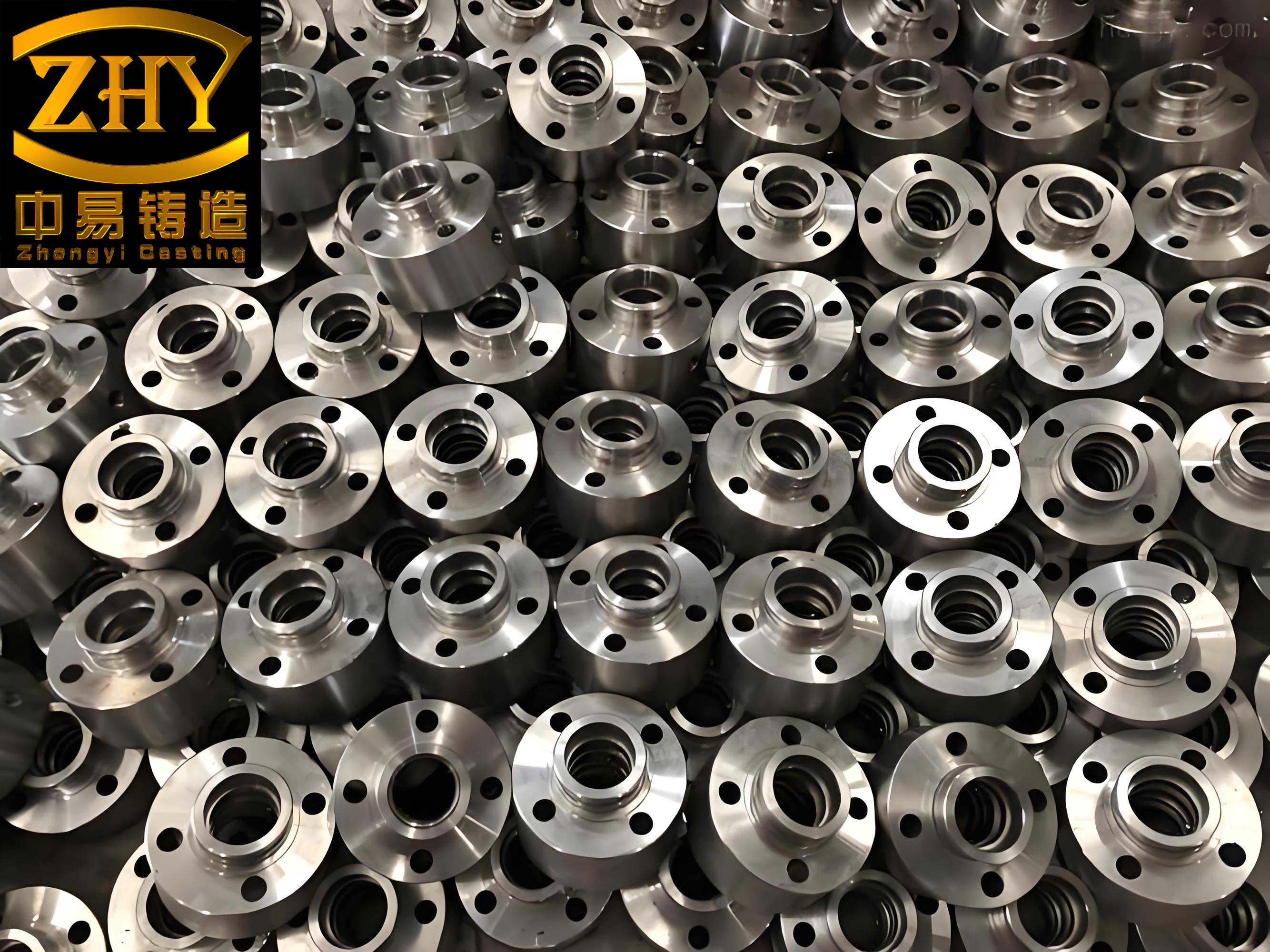

For over a decade, our foundry has specialized in the high-volume production of medium and small-sized nodular cast iron castings. Operating with vertically-parted flaskless molding lines and medium-frequency induction furnaces, we consistently achieved a respectable overall yield of approximately 90% for parts such as pipe clamps, flanges, and bushings, primarily in grades QT450-12 and QT500-7. However, reaching beyond this plateau proved exceptionally challenging. Defects like surface sinks, shrinkage porosity, cold shuts, and misruns, particularly in thin-walled sections (down to ~3 mm), persisted as significant barriers to further improvement in yield and quality consistency. This persistent challenge necessitated a technological evolution beyond traditional process control methods, leading to the integration of an intelligent control and prediction system specifically designed for nodular cast iron metallurgy. After several months of implementation, this system has delivered substantial technical and economic benefits, fundamentally enhancing our approach to quality control.

The traditional triad of molten metal control—chemical composition, temperature, and purity—while essential, presents an incomplete picture of metallurgical quality. Relying solely on spectrometry for chemical analysis and thermocouples for temperature measurement fails to capture dynamic parameters critical to the solidification behavior and final properties of nodular cast iron. Key metrics such as the true state of nodularization, the effectiveness of inoculation, and the inherent shrinkage tendency of the specific iron batch remained elusive until after solidification and machining, which is too late for corrective action.

Our production foundation was already robust. We utilize high-purity raw materials: Q10 pig iron, steel scrap, processed returns, and high-quality nodularizing and inoculating alloys. Melting is performed in medium-frequency induction furnaces, ensuring excellent homogeneity and minimal slag generation. Standard operating procedures strictly defined key parameters:

- Tap Temperature: 1,500 – 1,560°C.

- Post-Treatment Pouring Temperature: >1,400°C, with a maximum holding time of 7 minutes.

- Base Iron Chemistry (spectrometer-controlled):

- Carbon (C): 3.5 – 4.0%

- Silicon (Si): 1.4 – 2.1%

- Manganese (Mn): ≤ 0.4%

- Phosphorus (P): ≤ 0.08%

- Sulfur (S): ≤ 0.03%

- Treated Iron Chemistry:

- Carbon (C): 3.5 – 3.9%

- Silicon (Si): 2.4 – 3.2%

- Residual Magnesium (Mg): 0.025 – 0.06%

- Residual Rare Earths (RE): ≤ 0.02%

Despite this controlled environment, the final casting quality was not guaranteed, indicating that the static chemical composition targets were insufficient for predicting dynamic solidification outcomes.

Principles of the Intelligent Control System

The core innovation of the nodular cast iron intelligent system lies in its application of thermal analysis for real-time metallurgical assessment. The system operates in two key stages:

- Base Iron Analysis: Before treatment, a sample of the base iron is poured into a standardized thermal analysis cup. The cooling curve is analyzed to accurately determine the liquidus temperature and calculate the Carbon (C) and Silicon (Si) content via established relationships. More importantly, it calculates the Liquidus Carbon Equivalent (CEL), a crucial parameter for subsequent adjustment.

- Treated Iron Prediction: After the nodularizing treatment (using the sandwich method), a sample of the treated iron is poured into a special multi-sensor cup. The system acquires and analyzes the cooling curve in real-time. Advanced algorithms perform mathematical transformations on the curve, extracting key features such as the eutectic undercooling (ΔT), recalescence temperature, and the shape of the eutectic plateau.

From this data, the system predicts several critical metallurgical quality parameters before the iron is poured into molds:

- Predicted Nodularity (%): An estimate of the degree of spheroidization.

- Inoculation Index: A quantitative measure of the effectiveness of the inoculant.

- Eutectic Index (SI): Indicates the state of the iron relative to its true eutectic point.

- Shrinkage Tendency Index (SC): Predicts the propensity for shrinkage defects.

- Active Carbon Equivalent (ACE): The system’s most significant conceptual breakthrough.

The Paradigm Shift: Dynamic Eutectic Point and Active CE (ACE)

Traditional metallurgy for nodular cast iron often targets a fixed carbon equivalent, typically around 4.3%, calculated using a standard formula such as:

$$ CE = C\% + \frac{1}{3}(Si\% + P\%) $$

or, neglecting phosphorus:

$$ CE = C\% + 0.33Si\% $$

This static CE target is a fundamental misconception. The intelligent system demonstrates that the true eutectic point of nodular cast iron is not a fixed value but a dynamic parameter that shifts based on the exact chemical composition, particularly the Si content, and the state of nucleation (inoculation).

The system identifies the Active Carbon Equivalent (ACE) as the CE value corresponding to the minimum temperature on the eutectic plateau (TEU) of the treated iron’s cooling curve. When the liquidus temperature (TL) or the graphite nucleation temperature (TGL) coincides with TEU, the iron is at its true, dynamic eutectic composition for that specific melt. This ACE value can vary significantly from the theoretical 4.3%. The core principle for quality production is to adjust the base iron composition so that the treated iron’s ACE falls within an optimal range for the specific casting being produced, thereby minimizing shrinkage and maximizing graphite expansion during solidification.

Implementation and Chemical Composition Optimization

Using the intelligent system, we conducted extensive trials to correlate predicted parameters with actual casting defects. This data-driven approach allowed us to move from fixed chemical ranges to optimized, casting-specific targets. The system’s ability to instantly report predicted nodularity and shrinkage tendency enabled rapid, informed adjustments to the treatment process (e.g., nodularizer amount, inoculant type/amount) and base iron CEL.

For our range of pipe clamps, the optimization led to a significant shift in strategy. We moved from a single, high-CE approach for all sizes to a graded strategy where larger, more massive clamps required a lower base and final carbon content to avoid shrinkage, while maintaining adequate silicon for ferritization. The following table summarizes the optimized control ranges developed with the system’s guidance:

| Clamp Size (Inches) | Stage | C (%) | Si (%) | Residual Mg (%) | Target Liquidus CEL |

|---|---|---|---|---|---|

| 1-3 | Base Iron | 3.90 – 4.00 | 1.80 – 1.90 | – | ~4.55 |

| Treated Iron | 3.70 – 3.80 | 2.90 – 3.00 | 0.030 – 0.040 | – | |

| System Output | ACE ~4.35, Target Eutectic Index ~1.0 | ||||

| 4-6 | Base Iron | 3.85 – 3.95 | 1.80 – 1.90 | – | ~4.50 |

| Treated Iron | 3.65 – 3.75 | 2.80 – 2.90 | 0.035 – 0.045 | – | |

| System Output | ACE ~4.30, Target Eutectic Index ~1.0 | ||||

| 7-9 | Base Iron | 3.80 – 3.90 | 1.70 – 1.80 | – | ~4.40 |

| Treated Iron | 3.60 – 3.70 | 2.70 – 2.80 | 0.040 – 0.050 | – | |

| System Output | ACE ~4.25, Target Eutectic Index ~0.9 | ||||

| ≥10 | Base Iron | 3.75 – 3.85 | 1.60 – 1.70 | – | ~4.30 |

| Treated Iron | 3.55 – 3.65 | 2.60 – 2.70 | 0.045 – 0.055 | – | |

| System Output | ACE ~4.20, Target Eutectic Index ~0.9 | ||||

The system also provides typical target ranges for the predicted冶金 quality parameters, which are more informative than chemistry alone:

| Parameter | Symbol | Target Range (Typical) | Significance |

|---|---|---|---|

| Predicted Nodularity | – | > 80% (Aim >85%) | Ensures mechanical properties. |

| Inoculation Index | I.I. | 50 – 70 | Below 50 risks carbides; above 70 may indicate over-inoculation. |

| Eutectic Index | SI | 0.8 – 1.2 | SI ~1.0 = ideal eutectic. SI >>1 = hypereutectic (shrinkage risk). SI <<1 = hypoeutectic (carbide risk). |

| Shrinkage Tendency | SC | < 0.8 (Lower is better) | Direct indicator of shrinkage porosity risk. Values >1.0 indicate high risk. |

Case Studies: From Defect to Solution

The real power of the intelligent system is demonstrated in its problem-solving capability. Here are two detailed examples:

Case Study 1: Surface Sink Elimination in 3-Inch Pipe Clamp

Problem: 3-inch QT450-12 clamps exhibited chronic surface sink defects in thermal junctions.

Initial System Reading:

$$ C = 3.74\%,\quad Si = 2.74\% $$

Predicted Nodularity: 89%, Inoculation Index: 62, Eutectic Index (SI): 1.9, Shrinkage Index (SC): 0.9.

Diagnosis: The system flagged the iron as strongly hypereutectic (SI = 1.9). While nodularity and inoculation were good, the high SI and elevated SC confirmed a high shrinkage tendency, explaining the surface sinks.

Corrective Action: The base iron liquidus CEL was reduced from approximately 4.55 to 4.35 by lowering the carbon charge.

Resultant System Reading:

$$ C = 3.67\%,\quad Si = 2.74\% $$

Predicted Nodularity: 85%, Inoculation Index: 54, Eutectic Index (SI): 1.0, Shrinkage Index (SC): 0.72.

Diagnosis: The system now indicated a eutectic composition (SI ~1.0) with a significantly reduced shrinkage tendency (SC down to 0.72). The surface sink defects were completely eliminated in subsequent castings.

Case Study 2: Internal Shrinkage Porosity in a Hydraulic Component (QT550-6)

Problem: A new hydraulic component (Grade QT550-6) showed internal shrinkage porosity in heavy sections, failing radiographic inspection (Level 5-6 per ASTM E192).

Initial System Reading:

$$ C = 3.66\%,\quad Si = 3.05\% $$

Predicted Nodularity: 88%, Inoculation Index: 65, Eutectic Index (SI): 1.9, Shrinkage Index (SC): 0.84.

Diagnosis: Again, a hypereutectic condition (SI = 1.9) was identified as the root cause of the internal shrinkage.

Corrective Action: The base iron CEL was lowered from 4.51 to 4.34. Silicon was also slightly reduced to adjust the final matrix structure for higher strength.

Resultant System Reading:

$$ C = 3.71\%,\quad Si = 2.64\% $$

Predicted Nodularity: 84%, Inoculation Index: 52, Eutectic Index (SI): 1.0, Shrinkage Index (SC): 0.82.

Diagnosis: The iron was brought to a eutectic state (SI = 1.0). Subsequent castings were machined and inspected layer-by-layer. No shrinkage porosity was found, and radiographic inspection levels improved to a maximum of Level 3, fully meeting customer specifications.

Mathematical Foundations and Predictive Algorithms

The intelligence of the system is embedded in sophisticated algorithms that interpret the thermal analysis curve. While the exact proprietary formulas are complex, the underlying principles can be summarized. The system performs a real-time derivative analysis of the cooling curve to pinpoint critical temperatures with high precision (TL, TEU, TER).

The Eutectic Index (SI) is derived from the relationship between the eutectic undercooling and recalescence. A simplified conceptual representation is:

$$ S_I \propto \frac{\Delta T_{recalescence}}{\Delta T_{undercool}} $$

where a balanced ratio corresponds to SI ≈ 1.

Prediction of nodularity is based on empirical models correlating the characteristic shape and temperatures of the eutectic plateau with the final microstructure. These models are often of the form:

$$ Predicted Nodularity (\%) = f(T_{EU}, T_{ER}, \text{Curve Slope}_{eutectic}) $$

where \( f \) is a complex, multi-variable function derived from extensive regression analysis on thousands of paired thermal analysis and metallography results.

The most critical calculation is for the Active Carbon Equivalent (ACE). The system uses the measured TEU and an internal algorithm that accounts for the specific effects of Si and other elements on the depressed eutectic temperature in nodular cast iron, reversing the standard CE formula to solve for the equivalent carbon content at that precise solidification point.

Conclusion and Outlook

The integration of an intelligent control and prediction system has revolutionized our approach to nodular cast iron production. The key conclusions are:

- Beyond Traditional Metrics: Static chemical composition and temperature are necessary but insufficient for guaranteeing the quality of nodular cast iron. Dynamic冶金 quality parameters are essential for proactive control.

- The Dynamic Eutectic: The concept of a fixed eutectic point (CE=4.3%) is misleading for nodular cast iron. The Active Carbon Equivalent (ACE) is a dynamic parameter that must be targeted based on the specific casting and treatment process.

- Digital Process Control: The real-time, digital display of predicted nodularity, inoculation index, eutectic index, and shrinkage tendency provides foundry technicians with an unprecedented level of process insight and control, enabling immediate optimization.

- Foundation for Lean Management: This technology enables the precise design and control of nodular cast iron冶金 quality. It transforms casting from an art based on experience into a science based on data, reducing scrap, improving yield, and ensuring consistent quality—cornerstones of modern lean manufacturing.

The future of nodular cast iron foundries lies in the digitization and intelligent analysis of process data. Systems like the one described here are no longer just diagnostic tools but are becoming central process control units, paving the way for fully automated, closed-loop quality control in advanced nodular cast iron production.