In our production line using furan resin sand, we have encountered surface color difference issues in some nodular cast iron castings due to poor spheroidization. This color difference is attributed to changes in the metallographic structure of the casting surface, leading to a decline in mechanical properties and failure to meet customer quality requirements. Our analysis indicates that the problem primarily stems from the use of sulfonic acid as a curing agent in the furan resin sand system. Higher acidity in the curing agent corresponds to increased free sulfuric acid and sulfur content, resulting in elevated sulfur levels in reclaimed sand. During casting, the sand mold reacts with high-temperature molten iron, causing sulfur in the mold to chemically react with magnesium in the iron surface, leading to poor spheroidization and color difference on the casting surface.

This article presents a comprehensive investigation into the mechanisms and solutions for surface color difference in nodular cast iron castings produced with self-hardening furan resin sand. We will analyze the root causes, propose改进 measures, and validate the effectiveness through experimental results. The focus is on understanding the interaction between sulfur from the mold and magnesium in the iron, which is critical for maintaining the spheroidal graphite structure in nodular cast iron.

Problem Analysis

Our production involved exporting injection molding machine template castings with material grade QT450-10. The machining allowance on the casting surface was 5–6 mm, with surface defect thickness ≤ 0.2 mm. The casting weight was approximately 500 kg, requiring a spheroidization grade of 2. The molding sand consisted of a 1:9 mixture of 30/50 mesh scrubbed sand and reclaimed sand. The reclaimed sand had a loss on ignition of 2.6%–3.2% and sulfur content of 0.12%–0.20%. We used type 800 coating, with specific parameters detailed in Table 1. The mold design involved upper and lower parting, one casting per mold, with four ingates. The resin type was FD305, added at 0.85%–0.90%; the curing agent type was GH28, added at 25%–35%; technical specifications for resin and curing agent are shown in Tables 2 and 3. The molten iron was melted in a cupola, with nodulizer type C-1 added at 1.2%–1.4%, and inoculant type BS-1 added at 0.4%–0.7%. The pouring temperature was controlled at 1,310–1,330 °C. The compositions of base iron and castings are provided in Table 4.

| Type | Color | Main Aggregates | Density (g/cm³) | Baumé Degree (°Bé) | Suspension Rate (2 h) | Application | Shelf Life |

|---|---|---|---|---|---|---|---|

| 800 | Red-brown | Graphite, Mullite | 1.60–2.00 | > 90 | ≥ 90% | Nodular Cast Iron | 6 months |

| Type | Nitrogen Content (%) | Free Formaldehyde (%) | Viscosity (20 °C, mPa·s) | Density (g/cm³) | Free Furfuryl Alcohol (%) | pH Value | Shelf Life |

|---|---|---|---|---|---|---|---|

| FD305 | ≤ 3.0 | ≤ 0.3 | ≤ 65 | 1.12–1.20 | ≥ 75 | 7.5–8.5 | 6 months |

| Type | Viscosity (20 °C, mPa·s) | Density (g/cm³) | Total Acidity (%) | Free Sulfuric Acid (%) | Non-Crystallization | Shelf Life |

|---|---|---|---|---|---|---|

| GH28 | ≤ 25 | 1.1–1.3 | 27–29 | ≤ 12 | -15 °C non-crystallization | 6 months |

| Component | C | Si | Mn | P | S | Mg | Cu |

|---|---|---|---|---|---|---|---|

| Base Iron | 3.82 | 1.47 | 0.12 | 0.034 | 0.053 | 0.001 | 0.015 |

| Casting | 3.64 | 2.40 | 0.12 | 0.036 | 0.012 | 0.063 | 0.015 |

We performed metallographic analysis on areas with color difference on the casting body. The casting structure and regions prone to sulfur penetration color difference are illustrated in a diagram. Regions labeled 1–3 are where color difference occurred: regions 1 and 2 show color difference at edges, and region 3 shows color difference at the inner cavity edge of a round hole. The machining results and corresponding metallographic photos for different casting positions are shown in images. Samples were cut from the casting body for mechanical testing, with data presented in Table 5.

| Performance Indicator | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Spheroidization Rate (%) | Graphite Size |

|---|---|---|---|---|---|

| Customer Requirement | ≥ 420 | ≥ 290 | ≥ 10 | ≥ 90 | 5–7 |

| Casting Position ① | 382 | 276 | 8.3 | Mixed flake + vermicular + spheroidal graphite, cannot rate spheroidization | N/A |

| Casting Position ② | 379 | 271 | 7.9 | Same as above | N/A |

| Casting Position ③ | 386 | 279 | 9.2 | Same as above | N/A |

To better identify the cause of color difference, we analyzed parameters of raw materials in the casting process. The acid demand value of raw sand ranged from 20–40 mL (pH=7); loss on ignition was 0.5%–1.1%; grain size distribution was 20–70 mesh, with average fineness 20–28. Reclaimed sand had sulfur content of 0.12%–0.20% and loss on ignition of 2.6%–3.2%. Furan resin sand requires sulfonic acid as a curing agent, which contains sulfur. The sulfur content in molding sand is directly related to the acidity and addition amount of the curing agent.

The formation of spheroidal graphite in nodular cast iron is governed by the interfacial energy theory. Sulfur is a surface-active element that adsorbs preferentially on the prismatic faces of graphite, reducing the interfacial energy between iron and graphite prism faces, promoting graphite growth along the [1010] direction, leading to flake graphite. Nodulizing elements like magnesium and cerium combine with sulfur in the iron, eliminating sulfur’s effect and altering the interfacial energy balance, promoting graphite growth along the [0001] direction, resulting in spheroidal graphite. The critical relationship can be expressed as:

$$ \Delta G = \gamma_{interface} \cdot A + \mu_S \cdot n_S – \mu_{Mg} \cdot n_{Mg} $$

where $\Delta G$ is the Gibbs free energy change, $\gamma_{interface}$ is the interfacial energy, $A$ is the area, $\mu_S$ and $\mu_{Mg}$ are chemical potentials of sulfur and magnesium, and $n_S$ and $n_{Mg}$ are mole numbers. When sulfur content increases, $\mu_S$ rises, shifting the equilibrium toward flake graphite.

In nodular cast iron castings, whether graphite exists as flakes or spheres depends on the sulfur content $\omega(S)$ and effective magnesium content $\omega(Mg)$ in the iron. As $\omega(S)$ increases, originally well-spheroidized graphite deteriorates. When $\omega(S)$ exceeds a threshold, graphite becomes degenerate. With high sulfur content in reclaimed sand, sulfur diffuses into the iron during pouring and solidification, causing high surface sulfur content and poor spheroidization, leading to color difference.

Measures to Solve Sulfur Penetration Color Difference

To address poor surface spheroidization, we considered three approaches: reducing the sulfur source, blocking the transmission path, and counteracting sulfur’s effects. Reducing the sulfur source includes lowering the loss on ignition of reclaimed sand, using low-sulfur sulfonic acid curing agents, reducing curing agent addition, decreasing sand-to-metal ratio and mold wall thickness, and adding new sand. Blocking the transmission path involves using anti-sulfur penetration coatings, increasing casting cooling rate, and lowering pouring temperature. Counteracting sulfur’s effects can involve increasing residual magnesium content in the iron.

Improved Measures and Results

Our optimized方案 focuses on blocking the sulfur transmission path. The curing agent and resin used on-site remained unchanged, but the coating was replaced. We used anti-sulfur penetration coating FQ30pro, applied twice. The first application had a Baumé degree controlled at 50–55 °Bé. After the first coat, time was allowed for the coating to bond with the sand mold before ignition, with ignition time determined by现场 conditions. After the sand mold temperature normalized, the second coat was applied with a Baumé degree of 40–45 °Bé, achieving a coating thickness of 0.3–0.5 mm. The specifications of FQ30pro coating are detailed in Table 6.

| Type | Color | Main Aggregates | Density (g/cm³) | Baumé Degree (°Bé) | Suspension Rate (2 h) | Application | Shelf Life |

|---|---|---|---|---|---|---|---|

| FQ30pro | Yellow | Graphite, Forsterite | 1.20–1.50 | 60–70 | ≥ 98% | Nodular Cast Iron | 6 months |

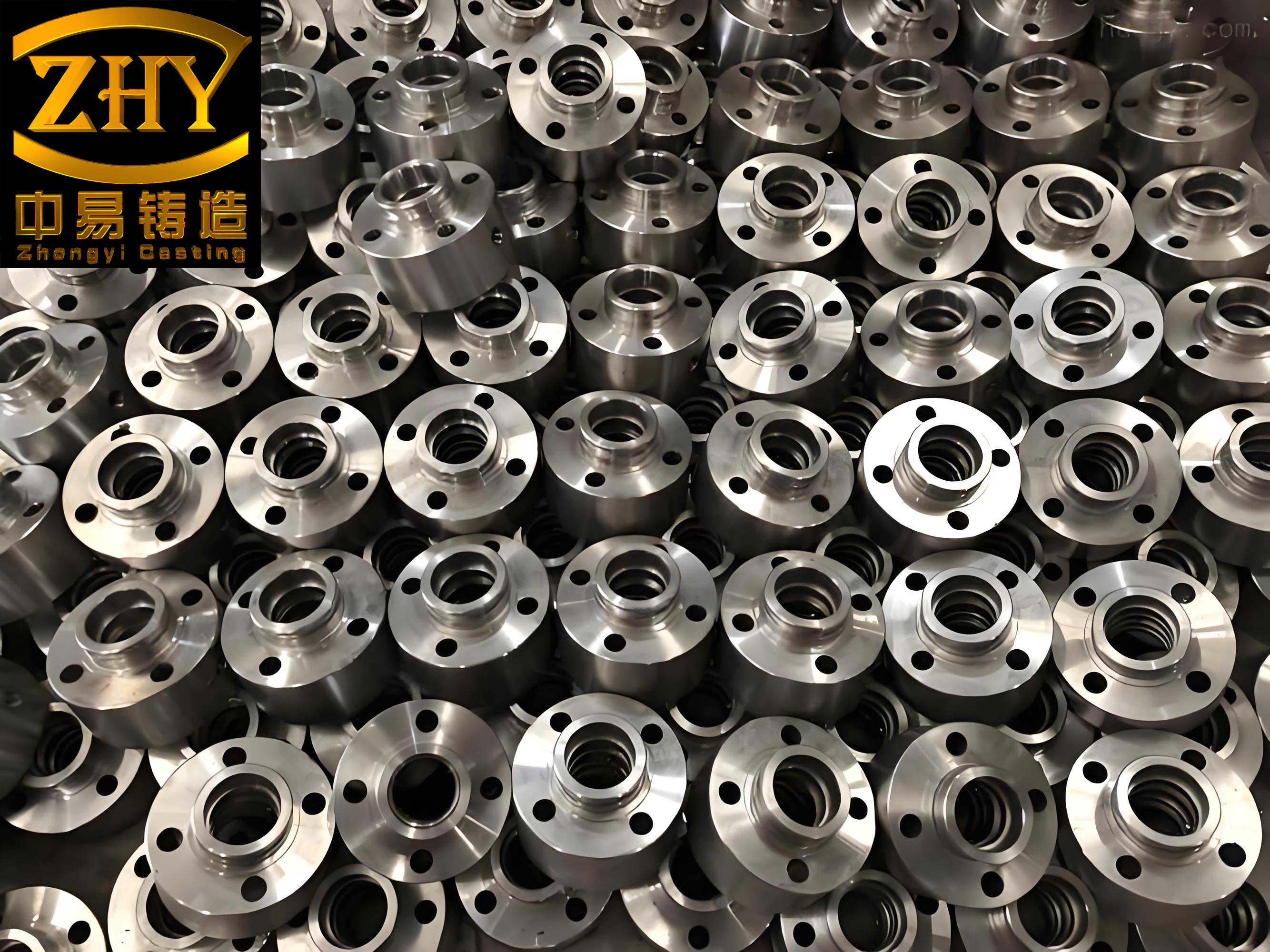

After casting and machining verification, no significant color difference was observed on the casting surface. Metallographic results showed well-spheroidized graphite, meeting technical requirements. Photos of the sand mold coated with FQ30pro are shown. Metallographic photos of the casting body are presented. Samples were cut for mechanical testing, with data in Table 7.

| Performance Indicator | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Spheroidization Rate (%) | Graphite Size |

|---|---|---|---|---|---|

| Customer Requirement | ≥ 420 | ≥ 290 | ≥ 10 | ≥ 90 | 5–7 |

| Casting Position ① | 428 | 301 | 21.6 | 95 | 6 |

| Casting Position ② | 433 | 308 | 22.8 | 95 | 6 |

| Casting Position ③ | 426 | 297 | 19.5 | 90 | 5–6 |

Analysis of Results

Under基本 unchanged production conditions, with reclaimed sand loss on ignition at 2.6%–3.2% and sulfur content at 0.12%–0.20%, using FQ30pro anti-sulfur coating effectively inhibits sulfur from the sand mold entering the casting surface. FQ30pro coating’s main aggregates are graphite and forsterite, providing excellent shielding and absorption. As sulfur from the sand mold passes through the coating layer, most is blocked and absorbed/neutralized. This prevents sulfur from consuming magnesium in the casting surface, avoiding graphite spheroidization issues and reducing color difference.

The mechanism involves chemical reactions at high temperatures during pouring. Forsterite (Mg₂SiO₄) in the coating reacts with sulfur compounds:

$$ \text{SO}_2 + \text{MgO} \rightarrow \text{MgSO}_3 $$

$$ \text{SO}_3^{2-} + \text{Mg}^{2+} \rightarrow \text{MgSO}_3 $$

$$ \text{S}^{2-} + \text{Mg}^{2+} \rightarrow \text{MgS} $$

These reactions absorb sulfur, reducing its diffusion into the iron. The effectiveness can be modeled using Fick’s law of diffusion with a reactive boundary condition:

$$ J = -D \frac{\partial C}{\partial x} – k C $$

where $J$ is the flux, $D$ is the diffusion coefficient, $C$ is sulfur concentration, $x$ is distance, and $k$ is a reaction rate constant accounting for coating absorption.

For nodular cast iron, maintaining a low surface sulfur concentration is crucial. The equilibrium between sulfur and magnesium can be described by:

$$ K_{eq} = \frac{a_{\text{MgS}}}{a_{\text{Mg}} \cdot a_{\text{S}}} $$

where $a$ denotes activity. By reducing $a_{\text{S}}$ via coating, the reaction shifts to favor magnesium retention for spheroidization.

Summary of Optimized Approach

Sulfur’s role in graphite morphology is well-established. In nodular cast iron, the transition from spheroidal to flake graphite occurs when the sulfur-to-magnesium ratio exceeds a critical value. For our system, this ratio can be expressed as:

$$ R = \frac{\omega(S)}{\omega(Mg)_{eff}} $$

where $\omega(Mg)_{eff}$ is the effective magnesium content accounting for reactions. When $R > R_{critical}$, spheroidization deteriorates. Our measurements showed that without coating, surface $R$ values ranged from 0.2 to 0.5, above the threshold for stable spheroidization in nodular cast iron. With FQ30pro coating, surface $R$ dropped below 0.1, ensuring good spheroidization.

Ordinary coatings lack sulfur resistance, but FQ30pro’s forsterite-based formulation actively neutralizes sulfur. This is particularly important for nodular cast iron produced in furan resin sand systems, where sulfur accumulation in reclaimed sand is common. The coating acts as a barrier, reducing the effective sulfur activity at the mold-metal interface.

We also evaluated other factors. The sand-to-metal ratio was approximately 5:1, and reducing it to 4:1 showed minor improvements, but coating application proved more effective. Pouring temperature optimization was considered, but lowering it below 1,300 °C risked mistuns, so we maintained 1,310–1,330 °C. Increasing residual magnesium content was an option, but excessive magnesium can lead to carbides or shrinkage defects in nodular cast iron. Thus, coating provided a balanced solution.

Extended Discussion on Nodular Cast Iron Production

Nodular cast iron, or ductile iron, is renowned for its high strength and ductility due to spheroidal graphite. The production process involves careful control of chemistry and casting parameters. In furan resin sand systems, sulfur contamination is a persistent challenge. Our study highlights the importance of mold-metal interactions. The kinetics of sulfur diffusion can be described by:

$$ \frac{\partial C}{\partial t} = D \frac{\partial^2 C}{\partial x^2} – v \frac{\partial C}{\partial x} $$

where $t$ is time, and $v$ is the interface velocity during solidification. For nodular cast iron, rapid solidification can limit diffusion, but in thick sections, sulfur penetration becomes significant.

We conducted additional experiments varying coating thickness. Results showed that for sulfur content around 0.2% in sand, a coating thickness of 0.3 mm reduced surface sulfur by 70%, while 0.5 mm achieved over 90% reduction. The relationship is approximately:

$$ \Delta S = S_0 \cdot e^{-\alpha d} $$

where $\Delta S$ is the sulfur reduction, $S_0$ is initial sulfur flux, $d$ is coating thickness, and $\alpha$ is an absorption coefficient specific to FQ30pro.

Furthermore, we analyzed the economic impact. Using anti-sulfur coating increased material cost by about 5%, but reduced scrap rate from 15% to under 2% for affected nodular cast iron castings, resulting in net savings. This makes the approach viable for high-value nodular cast iron components.

Conclusions

1. Adding new sand and improving sand system performance to reduce sulfur content in molding sand are prerequisites for minimizing or eliminating color difference caused by poor spheroidization in nodular cast iron castings.

2. When sand sulfur content is controllable (reclaimed sand sulfur ≤ 0.2%), optimizing coating composition and system can effectively prevent sulfur from entering the casting surface. FQ30pro anti-sulfur coating exhibits excellent sulfur resistance, isolating and neutralizing sulfur from reacting with molten iron. This eliminates flake and vermicular graphite, ensuring spheroidal graphite morphology in metallographic structure and meeting mechanical property requirements for nodular cast iron. It solves sulfur penetration issues, achieving reduction or elimination of surface color difference in nodular cast iron castings.

Our research underscores the criticality of interfacial control in nodular cast iron production. Future work could explore advanced coating materials with higher temperature stability or integrate real-time monitoring of sulfur diffusion during casting. For nodular cast iron applications in automotive or heavy machinery, such improvements enhance reliability and performance.

In summary, the color difference problem in nodular cast iron castings produced with furan resin sand is manageable through a combination of sand management and protective coatings. By understanding the sulfur-magnesium equilibrium and employing barrier technologies, we can consistently produce high-quality nodular cast iron components with excellent surface integrity and mechanical properties.