In industrial applications, white cast iron components, particularly those used in abrasive environments, demand a balance of high hardness and superior toughness to withstand severe wear and impact. My research focuses on improving the durability of blades employed in shot blasting equipment, which are typically made from high chromium white cast iron. These blades operate under extreme conditions, enduring repetitive impacts from high-velocity iron shots at stresses approaching 1000 MPa, leading to wear mechanisms such as impact deformation, abrasive cutting, and fatigue. Historically, the service life of these white cast iron blades was limited due to inadequate toughness, prompting a comprehensive study to refine their microstructure and properties through chemical adjustment, modification treatment, and process innovations.

The core objective was to transform the microstructure of high chromium white cast iron to promote a uniform martensitic matrix with finely dispersed, isolated carbides, thereby enhancing both wear resistance and impact toughness. This article details the multifaceted approach undertaken, encompassing alloy design, melt treatment, casting methodology, and heat treatment. The integration of modification principles, specifically through in-furnace treatment and secondary inoculation, proved pivotal in achieving significant life extension. Throughout this work, the term “white cast iron” is emphasized to underscore the material’s foundational role, and various analytical tools, including formulas and tables, are used to summarize key findings.

The degradation of white cast iron blades in shot blasting machines is a complex process involving cyclic stress and abrasive wear. Under operational loads, the surface undergoes plastic flow, work hardening, and micro-crack initiation. These cracks propagate under repeated impact, forming networks that eventually cause spalling or fracture. Therefore, a superior white cast iron grade must resist crack propagation through high toughness while maintaining sufficient hardness to mitigate cutting wear. Early versions of these blades used low nickel-chromium white cast iron, which offered limited improvement. Transitioning to high chromium white cast iron improved hardness but left toughness wanting. My investigation aimed to address this by holistically optimizing the material’s composition and processing.

Chemical Composition Adjustment for Optimized White Cast Iron

The initial step involved recalibrating the alloy composition to favor the formation of beneficial carbide types and a tougher matrix. In high chromium white cast iron, the ratio of chromium to carbon critically influences carbide morphology and volume fraction. The original composition, with approximately 12% Cr and 2.8-3.2% C, was modified to enhance performance. Table 1 summarizes the adjustments made to key elements.

| Element | Original Range | Adjusted Range | Primary Effect |

|---|---|---|---|

| Carbon (C) | 2.8 – 3.2 | 2.0 – 2.4 | Reduces carbide volume, increases toughness |

| Chromium (Cr) | ~12 | ~15 | Promotes M7C3 carbides, improves hardness & modifies morphology |

| Silicon (Si) | 0.6 – 1.0 | 0.6 – 1.0 | Maintained for fluidity and deoxidation |

| Manganese (Mn) | 0.4 – 0.8 | 0.4 – 0.8 | Maintained for solid solution strengthening |

| Copper (Cu) | ~0.5 | ~1.0 | Enhances hardenability and stabilizes austenite |

| Molybdenum (Mo) | ~0.8 | ~0.8 | Improves淬透性 (hardenability) and refines structure |

| Sulfur (S) | ≤0.06 | ≤0.06 | Minimized to reduce brittleness |

| Phosphorus (P) | ≤0.06 | ≤0.06 | Minimized to reduce brittleness |

Increasing chromium content to about 15% shifts the carbide equilibrium towards the harder M7C3 type (HV 1500-1800) over the less desirable M3C type (HV 800-1000). The Cr/C ratio is a vital parameter; for this white cast iron, it was targeted between 6.5 and 7.5 to optimize carbide isolation. The relationship can be approximated by considering the carbide stability region. The volume fraction of carbides \( V_c \) in white cast iron can be estimated using empirical formulas, such as:

$$ V_c \approx k \cdot (C\% – \alpha \cdot Cr\%) $$

where \( k \) and \( \alpha \) are constants dependent on alloying elements. For high chromium white cast iron, a simplified model suggests:

$$ V_c (\%) \approx 12.33 \cdot C\% + 0.55 \cdot Cr\% – 15.2 $$

By lowering carbon to 2.0-2.4%, the calculated carbide volume reduces to around 30-35%, which is ideal for balancing hardness and toughness. Excessive carbides increase brittleness, while insufficient carbides compromise wear resistance. The addition of molybdenum and copper enhances hardenability, preventing the formation of soft pearlite during cooling and promoting martensite formation. Copper, while stabilizing austenite, is controlled to avoid excessive retained austenite after heat treatment.

Modification Treatment: Principles and Application to White Cast Iron

The modification of white cast iron melt is a cornerstone of this study, aimed at refining carbide morphology, enhancing matrix uniformity, and improving grain boundary integrity. Modification involves adding small amounts of active elements that alter solidification kinetics, leading to finer, more isolated carbides and a denser austenitic matrix. For high chromium white cast iron, this treatment is crucial for achieving high impact toughness without sacrificing hardness.

The mechanism relies on selective adsorption of modifier elements on growing carbide faces. During eutectic solidification, active elements like rare earths segregate to preferred growth directions of carbides, inhibiting atom attachment and slowing growth. This forces carbides to become smaller and blunter. Simultaneously, eutectic austenite envelops carbides, further restricting growth and promoting a discontinuous network. Other elements in the modifier enhance austenite nucleation, leading to grain refinement. Additionally, grain boundary purification occurs, reducing impurity segregation and strengthening intergranular bonds, which suppresses micro-crack initiation.

The modifier composition was carefully designed, and its application process was optimized. Table 2 outlines the modifier formulation and treatment parameters.

| Component | Percentage in Modifier | Function |

|---|---|---|

| Rare Earth Silicon Iron (FeSiRE21) | 65% | Primary modifier for carbide morphology control and deoxidation |

| Rare Earth Silicon Magnesium Iron (FeSiMg8RE5) | 15% | Enhances inoculation effect and spheroidization potential |

| Pure Aluminum (Al) | 20% | Strong deoxidizer, improves melt cleanliness |

The total modifier addition was 0.35-0.40% of the iron melt weight. The treatment sequence is critical: first, the white cast iron melt was superheated to 1500°C in a medium-frequency induction furnace (150-250 kg capacity) and thoroughly deoxidized. Slag was removed, and a preheated modifier packet, compacted into blocks, was plunged into the melt using a bell jar to a depth of 3/4 of the melt height. Gentle stirring for 0.5-1.0 minute ensured uniform dispersion. After reaction completion, the melt was immediately tapped into a ladle for secondary inoculation with 0.1% FeSi75 ferrosilicon. Pouring temperatures were maintained at 1500-1530°C for tapping and 1430-1450°C for casting.

The effectiveness of modification on white cast iron microstructure can be quantified by considering carbide aspect ratio and inter-carbide spacing. A refined microstructure leads to improved mechanical properties. The Hall-Petch relationship, often used for grain size strengthening, can be adapted for carbide spacing \( \lambda \) in white cast iron:

$$ \sigma_y = \sigma_0 + k_y \cdot \lambda^{-1/2} $$

where \( \sigma_y \) is yield strength, \( \sigma_0 \) is friction stress, and \( k_y \) is a constant. Reduction in \( \lambda \) through modification enhances strength and toughness. Additionally, the impact toughness \( a_K \) correlates with carbide morphology, approximated by:

$$ a_K \propto \frac{1}{\sqrt{d_c}} $$

where \( d_c \) is the average carbide size. Modification significantly reduces \( d_c \), thereby increasing \( a_K \).

Casting Process Innovation for White Cast Iron Blades

The geometry of the blade, weighing approximately 1.15 kg, required a casting method that ensured soundness and directional solidification. Originally, blades were cast horizontally, which often led to centerline shrinkage porosity, weakening the part. To address this, the orientation was changed to an 18-degree upward tilt, enhancing thermal gradients and promoting sequential solidification from the tip toward the feeding riser.

This adjustment in the casting process for white cast iron components eliminated internal defects, resulting in denser metal with improved mechanical integrity. The revised gating system also optimized yield, increasing the casting yield from 50% to 68%. A schematic description of the process emphasizes the tilted placement, with the sprue and riser arranged to facilitate smooth metal flow and effective feeding. The solidification time \( t_s \) for a simple shape can be estimated using Chvorinov’s rule:

$$ t_s = B \cdot \left( \frac{V}{A} \right)^n $$

where \( V \) is volume, \( A \) is surface area, \( B \) is a mold constant, and \( n \) is an exponent (typically ~2). Tilting increases the effective cooling area for critical sections, reducing local \( t_s \) and minimizing shrinkage. This process refinement is vital for producing defect-free white cast iron castings that can withstand high-stress service.

Heat Treatment Optimization for High Chromium White Cast Iron

Heat treatment transforms the as-cast microstructure of white cast iron into a wear-resistant state. The goal is to obtain a matrix of predominantly martensite with finely dispersed carbides and a minimal amount of retained austenite. The process involves austenitization, cooling, and tempering.

Austenitization was conducted at 960°C, elevated from the previous 940°C, to ensure complete dissolution of carbides and homogenization of austenite. The holding time was extended to 4 hours (from 2 hours) to account for the austenite-stabilizing effect of copper (~1.0%). This prolonged soaking allows for precipitation of secondary carbides, which reduces carbon and chromium in austenite, raising the martensite start temperature \( M_s \). The \( M_s \) temperature can be estimated using empirical formulas for white cast iron, such as:

$$ M_s (°C) = 539 – 423 \cdot C\% – 30.4 \cdot Mn\% – 17.7 \cdot Cr\% – 12.1 \cdot Mo\% – 7.5 \cdot Cu\% $$

For the adjusted composition, this yields an \( M_s \) sufficiently high to ensure martensite transformation upon cooling. Cooling was performed in still air instead of oil quenching, as the blade’s thin section allows adequate hardening without quenching stresses. Air cooling minimizes distortion and crack risk while achieving the desired martensitic structure in this white cast iron.

Tempering was immediately carried out at 250°C for 2 hours to relieve internal stresses from the martensitic transformation, which involves a volume expansion of about 6%. The tempering kinetics can be described by the Hollomon-Jaffe parameter for tempering effects:

$$ P = T \cdot (\log t + C) $$

where \( T \) is temperature in Kelvin, \( t \) is time in hours, and \( C \) is a constant. This parameter helps predict hardness retention after tempering for white cast iron components.

The heat treatment cycle is summarized in a step-wise diagram: austenitize at 960°C for 4h, air cool to room temperature, then temper at 250°C for 2h. This regimen produces a hardness of HRC 60-62 with enhanced toughness.

Performance Evaluation and Conclusions on White Cast Iron Blades

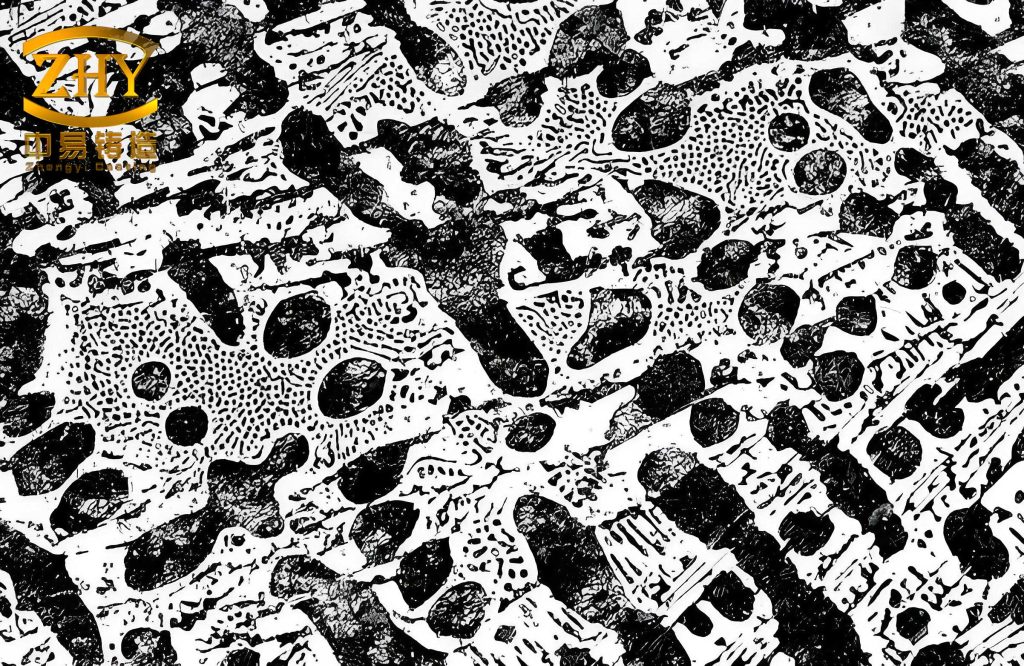

The combined improvements in composition, modification, casting, and heat treatment led to remarkable gains in the performance of white cast iron blades. Microstructural analysis revealed a dramatic refinement: carbides appeared as small, isolated particles in a uniform martensitic matrix, with clean grain boundaries. This directly translated to superior mechanical properties.

Hardness consistently measured HRC 60-62, while impact toughness \( a_K \) reached 7.1-9.5 J/cm², a substantial increase over prior versions. Service life tests under operational conditions showed that using 6-8 mm iron shots, blade life extended from 15 hours to over 35 hours; with 3-4 mm shots, life increased from 30 hours to over 80 hours. Thus, the service life of these high chromium white cast iron blades more than doubled, validating the efficacy of the integrated approach.

Key insights from this work on white cast iron include: maintaining a low carbon content (preferably ≤2.2%) and a Cr/C ratio between 6.5-7.5 optimizes carbide morphology and volume; modification treatment is indispensable for toughness enhancement through carbide refinement and grain boundary strengthening; and proper heat treatment with adjusted parameters ensures a balanced microstructure. The successful application of these principles demonstrates the potential for further advancements in white cast iron technology for abrasive wear applications.

Future work could explore the use of computational thermodynamics to predict phase equilibria in white cast iron, or investigate the effects of other modifier elements like titanium or boron. Additionally, fatigue crack propagation studies in modified white cast iron could provide deeper insights into longevity under cyclic loading. Ultimately, the continuous evolution of white cast iron processing will enable even more durable components for industrial use.