In my extensive research and industrial experience, the development of advanced grinding media for large-scale ball mills in mining operations has always been a critical focus. The pursuit of materials that combine high wear resistance with cost-effectiveness led our team to investigate and develop a novel type of low-carbon alloy white cast iron grinding ball. This white cast iron variant is specifically engineered for the demanding conditions of wet grinding in large, grate-discharge ball mills. The fundamental innovation lies in its microstructure, which features a troostitic matrix, blocky alloy carbides, and enhanced toughness, all achieved through precise compositional control and specialized casting processes. The primary objective was to create a white cast iron grinding medium that significantly outperforms conventional forged steel balls in terms of wear life and operational economics, while maintaining sufficient impact resistance to prevent catastrophic failure in service.

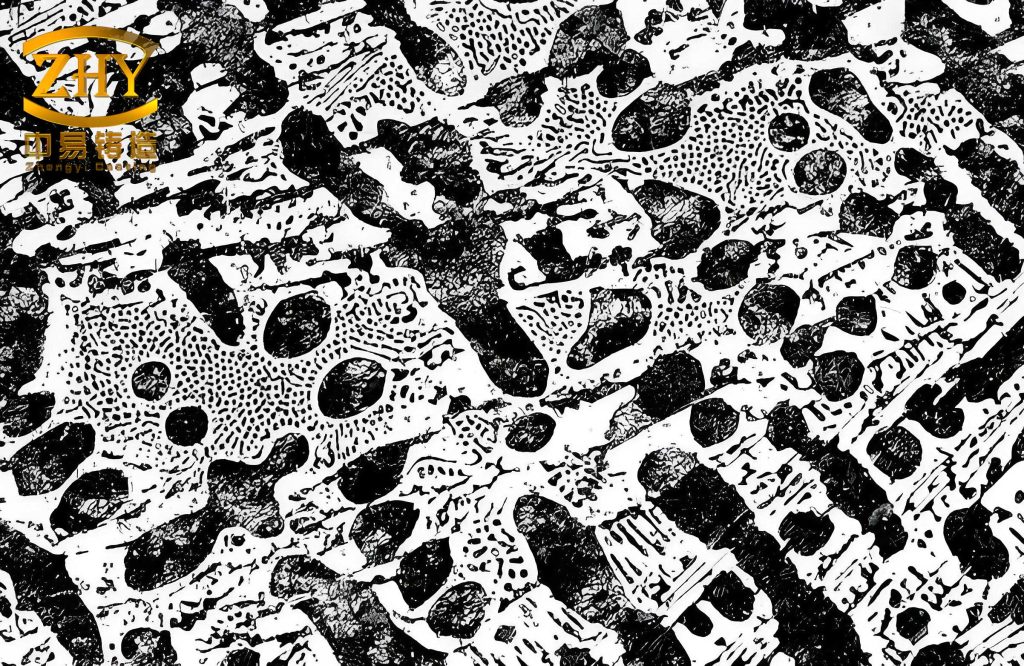

The core material is a low-carbon alloy white cast iron. The term “white cast iron” denotes a family of cast irons where the carbon is predominantly in the form of hard, abrasive carbides, leading to exceptional wear resistance but often at the expense of toughness. Our formulation deliberately reduces the total carbon content and strategically employs alloying elements like chromium and molybdenum to modify the carbide morphology and matrix structure. This approach mitigates the inherent brittleness often associated with traditional white cast iron. The chemical composition was meticulously designed to promote the formation of isolated, blocky (M7C3 and M23C6) carbides within a fine, transformed matrix, rather than the continuous, brittle network found in ledeburitic white cast iron. A key aspect of the manufacturing process is the use of chill casting, which induces directional solidification, resulting in a radial columnar grain structure from the core to the surface. This refined microstructure, combined with a low-temperature stress-relief heat treatment (aging), allows the balls to be used in the as-cast state, eliminating the need for costly and energy-intensive quenching and tempering cycles often required for other alloyed white cast iron grades.

The performance evaluation was conducted through rigorous industrial trials, comparing these low-carbon alloy white cast iron balls against standard carbon steel forged balls in identical Φ3.2m x 4.5m ball mills processing molybdenum ore. The most critical metric, specific ball consumption (weight loss per ton of ore ground), was meticulously monitored. The economic analysis transcends simple wear rates by incorporating relative cost factors. We define the Relative Wear Resistance (RWR) as the percentage reduction in specific consumption compared to the standard steel ball baseline:

$$ \text{RWR} = \left(1 – \frac{\text{Specific Consumption}_{\text{White Cast Iron}}}{\text{Specific Consumption}_{\text{Steel}}}\right) \times 100\% $$

Furthermore, to account for differing manufacturing costs, we introduce the concept of Relative Cost (RC), which is the ratio of the price of the white cast iron ball to the price of the standard steel ball. The ultimate measure of value, the Relative Economic Benefit (REB) or unit cost wear resistance, is then the ratio of RWR to RC. A higher REB indicates a more cost-effective grinding medium.

The results from our trials were compelling and are summarized comprehensively in the table below, which also includes comparative data for other commercially available wear-resistant ball types based on pearlitic white cast iron matrices.

| Grinding Media Type | Specific Consumption (kg/t ore) | Relative Wear Resistance, RWR (%) | Relative Cost, RC (vs. Steel Ball=1.0) | Relative Economic Benefit, REB (RWR/RC) |

|---|---|---|---|---|

| Standard Forged Steel Ball (Baseline) | 1.20 | 0.0 | 1.00 | 0.0 |

| Low-Carbon Alloy White Cast Iron Ball (This Work) | 0.72 | 40.0 | 1.65 | 24.24 |

| Low-Chromium Alloy White Cast Iron Ball | 0.85 | 29.2 | 1.55 | 18.84 |

| Medium-Manganese Steel Ball | 1.05 | 12.5 | 1.30 | 9.62 |

| High-Manganese Steel Cast Ball | 0.95 | 20.8 | 1.80 | 11.56 |

| Multi-Component Alloy White Cast Iron Ball | 0.78 | 35.0 | 1.75 | 20.00 |

The data unequivocally demonstrates the superior performance of our low-carbon alloy white cast iron grinding ball. It achieved the highest Relative Wear Resistance (40%) among the compared media, leading to a direct reduction in ball consumption of 0.48 kg per ton of ore. When factoring in costs, its REB of 24.24 is the highest, indicating it delivers the most wear resistance per unit of cost invested. The financial impact is substantial. For an annual ore processing volume of 10 million tons, the switch from standard steel balls to this white cast iron alternative translates to a saving of 4,800 tons of grinding media and annual cost savings exceeding 4.8 million currency units, based on local price structures. This underscores the significant economic advantage of this advanced white cast iron material.

The exceptional economic performance is rooted in its superior technical properties. The mechanical and microstructural characteristics of this white cast iron were thoroughly investigated using modern analytical techniques including scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) and transmission electron microscopy (TEM). A comparative analysis of key properties against other pearlitic white cast iron balls is presented below.

| Property / Material Type | Low-Carbon Alloy White Cast Iron Ball (This Work) | Low-Chromium Alloy White Cast Iron Ball | Multi-Component Alloy White Cast Iron Ball |

|---|---|---|---|

| Microstructure | Troostite matrix + Blocky (Cr,Fe)7C3 carbides, radial columnar grains | Pearlite + (Cr,Fe)7C3 network/blocky carbides | Pearlite/Bainite + complex alloy carbides |

| As-Cast Surface Hardness (HRC) | 58 – 62 | 56 – 60 | 58 – 63 |

| In-Service Hardened Surface (HRC) | 62 – 66 | 60 – 63 | 62 – 65 |

| Impact Toughness, ak (J/cm²) – As-cast specimen | 8.5 – 10.5 | 6.0 – 8.0 | 7.0 – 9.0 |

| Breakage Rate in Service (%) | < 0.5 | < 1.0 | < 0.8 |

The technical advantages of this specific white cast iron formulation are multifaceted. The low carbon content (typically below 2.8%) is crucial. It limits the total volume fraction of carbides, preventing the formation of a continuous, brittle carbide network. The strategic addition of chromium (around 2.0-3.0%) promotes the formation of hard, blocky (Cr,Fe)7C3 carbides instead of the softer cementite (Fe3C). The morphology and distribution of these carbides are central to the performance of this white cast iron. The blocky carbides act as ideal wear-resistant particles embedded in a tough matrix. Molybdenum (around 0.5-1.0%) is a potent solid-solution strengthener and a strong carbide former. Its primary role in this white cast iron is to increase hardenability, allowing the transformation of the austenite matrix into fine troostite (a very fine pearlitic structure) even under relatively slow cooling conditions of a sizable casting. This yields a matrix with high strength and good toughness without requiring post-cast heat treatment. The troostitic matrix hardness can be approximated by a relationship considering the alloying elements:

$$ H_{matrix} \approx H_0 + k_{Cr}\cdot\%Cr + k_{Mo}\cdot\%Mo + k_{Si}\cdot\%Si $$

where $H_0$ is the base hardness of ferrite/pearlite and $k$ values are strengthening coefficients.

The chill casting process is not merely a shaping operation but a critical microstructural control step. The rapid heat extraction at the mold wall creates a steep thermal gradient, forcing directional solidification. This results in the previously mentioned radial columnar grain structure. This refined, oriented structure has several benefits for a white cast iron grinding ball: it minimizes random grain boundaries that can be paths for crack propagation, it aligns the hard phases more favorably to resist abrasive wear, and it reduces microscopic segregation. Furthermore, industrial trials confirmed a desirable phenomenon: the surface of this white cast iron ball undergoes work hardening during service. The repeated impacts in the mill cause additional strain-induced transformation and hardening in the near-surface matrix, increasing the surface hardness from an as-cast value of approximately HRC 60 to over HRC 64. This dynamic hardening response, characteristic of some metastable austenitic steels but notably achieved here in a predominantly troostitic white cast iron, creates a “self-optimizing” wear surface.

The wear mechanism of this white cast iron in wet grinding applications involves both micro-abrasion and micro-fatigue. The hard, blocky carbides protrude slightly from the matrix and act as primary barriers to abrasion by ore particles. The tough troostite matrix supports these carbides, preventing their premature fracture or pull-out. The wear rate $W$ can be modeled as a function of material parameters and operational conditions. A simplified form of the Archard wear equation, modified for abrasive wear in white cast iron, can be expressed as:

$$ W = K \cdot \frac{P \cdot L}{H_{eff}} $$

where $W$ is the volume loss, $K$ is a wear coefficient dependent on the abrasive environment, $P$ is the applied load, $L$ is the sliding distance, and $H_{eff}$ is the effective hardness of the composite white cast iron microstructure. For our material, $H_{eff}$ is not simply the bulk hardness but a weighted function of the hardness of the carbides ($H_c$) and the matrix ($H_m$), and their volume fractions ($f_c$, $f_m$):

$$ H_{eff} \propto f_c \cdot H_c^{n} + f_m \cdot H_m^{n} $$

where the exponent $n$ reflects the load-sharing behavior between phases. The optimized blocky carbide morphology in our white cast iron maximizes $H_{eff}$ for a given carbide volume, leading to the low wear rates observed.

Beyond wear resistance, impact toughness is a vital safety and operational parameter. The measured impact toughness of 8.5-10.5 J/cm² from specimens taken from the ball本体 (body) is remarkably high for a material of this hardness class in the white cast iron family. This is a direct consequence of the combined effects of low carbon, blocky carbides, and the fine, strong troostite matrix. The low breakage rate of less than 0.5% in large-diameter mills validates this toughness, ensuring stable mill operation without the risks associated with fragmenting grinding media. An interesting correlation observed in our studies links toughness to the carbide spacing $\lambda$ in the white cast iron. A modified Griffith-type relation for fracture initiation in such composites suggests:

$$ \sigma_f \propto \frac{K_{IC}}{\sqrt{\pi \cdot \lambda}} $$

where $\sigma_f$ is the fracture stress and $K_{IC}$ is the fracture toughness of the matrix. The chill casting process refines $\lambda$, thereby increasing $\sigma_f$ and the effective impact resistance.

The discussion naturally extends to the broader context of grinding media selection. While high-chromium white cast irons (typically with >12% Cr) are renowned for extreme wear resistance, their higher cost and often required heat treatment make them less economically viable for many large-scale mining applications where impact conditions are severe. Our low-carbon, low-to-medium chromium white cast iron occupies a strategic performance niche. It offers a balanced property profile that is “fit-for-purpose” for large ball mills where impact forces are significant but not extreme, and where wet corrosion is a factor. The elimination of the heat treatment step is a major economic and environmental advantage, reducing energy consumption and production cycle time. This makes the overall lifecycle assessment of this white cast iron product very favorable compared to many alternatives.

In conclusion, based on my research and the extensive industrial trials, the developed low-carbon alloy white cast iron grinding ball represents a significant advancement in grinding media technology. The systematic study of its solidification, microstructure, and properties through advanced characterization techniques provided a solid theoretical foundation for its design. The key achievement is the creation of a white cast iron material that delivers an optimal combination of high hardness, exceptional wear resistance, and sufficient toughness directly in the as-cast and aged condition. The technical indicators, particularly the specific consumption of 0.72 kg/t and the corresponding 40% reduction compared to standard steel balls, are leading figures within the category of pearlitic white cast iron grinding media. The economic analysis confirms its superiority, with the highest Relative Economic Benefit among comparable products. The potential for widespread adoption in the mining industry is enormous, promising substantial reductions in steel consumption, grinding media costs, and even improvements in grinding efficiency through more stable charge dynamics. Therefore, I strongly advocate for the rapid scaling up of production capacity and the broad implementation of this low-carbon alloy white cast iron grinding ball technology across suitable mineral processing operations. Its performance demonstrates that innovative metallurgical design in white cast iron can yield solutions that are both technically excellent and economically transformative.