Raw materials: high purity pig iron (jbt11994-2014), 75 ferrosilicon;

Spheroidizer: mgre6-l rare earth magnesium spheroidizer, particle size 4? 25mm;

Inoculant: high calcium barium inoculant, particle size 3-8mm; sulfur oxygen inoculant, particle size 0.3-0.8mm.

The self-designed 16 channel temperature measurement system was used to measure the temperature of 45 ° fan-shaped test block and casting mold accurately; the mechanical properties were tested by sht4605 microcomputer controlled electro-hydraulic servo universal testing machine; the microstructure of the sample was observed by Leica dmilm metallographic microscope.

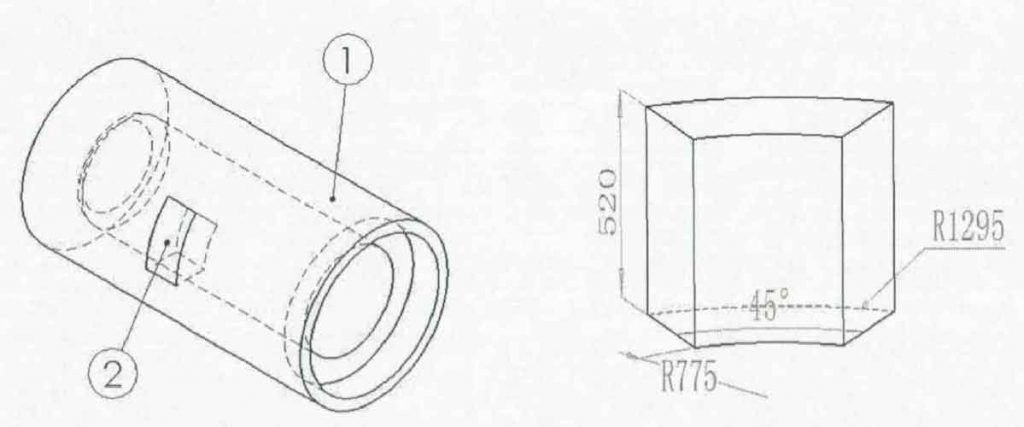

The 45 ° fan-shaped test block is designed and poured. The 45 ° fan-shaped test block is taken from the height of 1 / 2 of the 100 ton ductile iron spent fuel container, and the fan-shaped area accounts for 1 / 8 of the cross section of the spent fuel container. The position and geometric dimension of the 45 ° sector test block with height of 520mm, wall thickness of 520mm and weight of 1.7t are shown in the figure. The 16 channel temperature measurement system is used to accurately collect the temperature of the 45 ° fan-shaped test block and the mold. Through dissecting the 45 ° fan-shaped test block, the microstructure and properties are analyzed, and the quality control measures for controlling the large section ductile iron spent fuel container are mastered.