This article delves into the sand treatment systems in 3D printing smart foundries. It first presents an overview of the 3D printing casting process and its significance in the foundry industry. Then, it elaborates on the sand treatment system’s ,including new sand addition, sand recycling, and regeneration. The key equipment involved, such as ,magnetic separation devices, equipment, and screening devices, is introduced in detail. Additionally, the article discusses the advantages and challenges of 3D printing in foundries and provides a future outlook on the development of sand treatment systems in this context. Through comprehensive research and analysis, it aims to provide a thorough understanding of this emerging technology and its potential for the foundry industry.

1. Introduction

1.1 The Rise of 3D Printing in the Foundry Industry

In recent years, 3D printing technology has witnessed remarkable growth and has found extensive applications in various industries, including the foundry sector. The traditional foundry processes often face limitations in terms of complexity, cost, and production efficiency. 3D printing, on the other hand, offers a revolutionary approach by enabling the creation of complex geometries with high precision and flexibility. It allows for rapid prototyping and short – run production, reducing lead times and costs associated with tooling.

1.2 Significance of Sand Treatment Systems in 3D Printing Foundries

In 3D printing casting, sand is a crucial raw material. The quality of the sand directly affects the quality of the castings. A well – designed sand treatment system ensures that the sand used in 3D printing meets the required specifications. It is responsible for preparing the sand, recycling used sand, and regenerating it to a usable state. This not only improves the quality of the castings but also reduces the environmental impact by minimizing waste and the consumption of new sand.

2. 3D Printing Casting Process: An Overview

2.1 Principle of 3D Printing Casting

3D printing casting involves the layer – by – layer deposition of sand mixed with a binder. The process starts with a digital model of the desired casting. This model is sliced into thin layers, and the 3D printer then deposits the sand – binder mixture layer by layer, selectively solidifying the areas where the sand needs to be bonded to form the sand mold or core. Once the printing is complete, the sand mold or core is cured, and the casting process can begin.

2.2 Advantages of 3D Printing Casting over Traditional Methods

| Advantages | Description |

|---|---|

| Complex Geometry | Can create intricate shapes that are difficult or impossible to achieve with traditional casting methods. |

| Design Flexibility | Allows for easy design changes without the need for expensive tooling modifications. |

| Short Lead Times | Reduces the time from design to production, enabling rapid prototyping and quick response to market demands. |

| Cost – effective for Small Batches | Economical for producing small quantities as it eliminates the high costs associated with tooling for large – scale production. |

3. Sand Treatment System in 3D Printing Smart Foundries

3.1 Process Flow

3.1.1 New Sand Addition

New sand addition is an important step in the sand treatment system. The quality of the new sand can vary, and depending on its quality, it can be added at different stages. If the new sand has impurities or a high moisture content, it is advisable to add it at the 落砂 stage. This allows the sand to be processed through the entire sand treatment system, including the 热法再生 system, where it can be baked to improve its quality. On the other hand, if the new sand is of good quality, it can be added after the 热法再生 process, directly into the 发送罐 and then sent to the printer’s 缓存砂斗 for use.

3.1.2 Sand Recycling

After the 3D – printed sand mold or core is used for casting, the sand is recovered. The sand that falls off during the casting process and the sand from the used mold or core are collected. This recycled sand can be reused, which not only saves costs but also reduces the environmental impact. The recycled sand is sent back to the printer’s 缓存砂斗 after passing through some basic processing steps such as screening and magnetic separation to remove any impurities.

3.1.3 Sand Regeneration

Sand regeneration is a crucial process in the sand treatment system, especially for resin – bonded sands. The used sand often has a layer of binder on its surface, which affects its performance if reused directly. 热法再生设备 is used to remove this binder layer. The sand is first 破碎 into small particles and then heated to a high temperature in the 热法再生焙烧炉. The binder on the sand surface decomposes at high temperatures, and the sand is then cooled, screened, and stored in the 再生砂库. The regenerated sand can be used as new sand, reducing the consumption of fresh sand and saving costs.

3.2 Key Equipment

3.2.1 Shakeout Machines

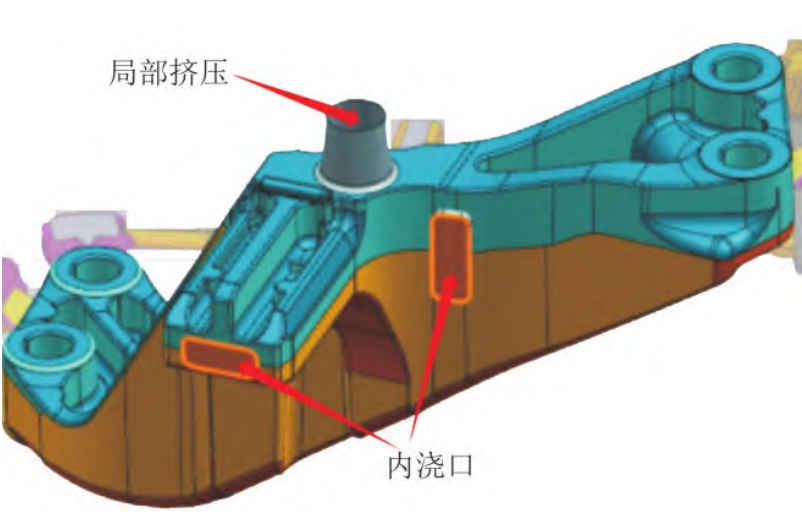

Shakeout machines play a vital role in separating the castings from the sand molds. There are two common types: vibrating shakeout machines and drum – type shakeout machines. In 3D printing foundries, the sand molds are often stronger than those in traditional hand – molding processes. Vibrating shakeout machines work by vibrating the sand mold, causing the castings and sand to collide and rub against the bed of the machine, facilitating their separation.

| Shakeout Machine Type | Working Principle | Advantages | Disadvantages |

|---|---|---|---|

| Vibrating Shakeout Machine | Generates periodic vibrations to make the castings and sand collide and rub against the bed | High separation efficiency, suitable for various sand mold strengths | May cause excessive wear on the sand mold and equipment if not properly adjusted |

| Drum – Type Shakeout Machine | Rotates the sand mold in a drum – shaped container to separate the castings and sand | Gentle on the sand mold, less likely to cause damage to the mold structure | Lower separation efficiency compared to vibrating shakeout machines |

3.2.2 Magnetic Separation Devices

Magnetic separation devices are used to remove magnetic impurities from the sand. After the casting process, the used sand often contains fragments of 浇冒口,铁片,铁豆,飞边毛刺,and 冷铁. These impurities can affect the quality of the sand and damage the equipment if not removed. Magnetic separation devices use magnetic fields to attract and separate these magnetic materials from the sand.

3.2.3 Thermal Regeneration Equipment

Thermal regeneration equipment is designed to restore the used sand to a usable state. It consists of a series of processes including 破碎,冷却,磁选,筛分,and high – temperature baking. The high – temperature baking process is the key step, where the binder on the sand surface is burned off, and the sand is then sieved to the required particle size. The regenerated sand has a more uniform particle size, lower dust content, and higher thermal stability, which is beneficial for improving the quality of the castings.

3.2.4 Screening Devices

Screening devices are used to separate sand particles of different sizes. In resin – sand processes, vibrating screens and 摇摆筛 are commonly used. The choice between these two types of screens depends on factors such as the production environment and the required screening efficiency. Vibrating screens are suitable for high – volume screening, while 摇摆筛 can provide a more precise separation of sand particles.

| Screening Device Type | Working Principle | Suitable for |

|---|---|---|

| Vibrating Screen | Generates vibrations to make the sand particles move and pass through the screen | High – volume screening, separating sand particles in a relatively wide range of sizes |

| Swing Screen | Moves in a swinging motion to separate sand particles | Precise separation of sand particles, suitable for applications where a specific particle size range is required |

3.2.5 Conveying Equipment

Conveying equipment is essential for transporting sand within the sand treatment system. There are two main types: mechanical conveying equipment and pneumatic conveying equipment. Mechanical conveying equipment includes vibrating conveyors, 螺旋输送机,带式输送机,and 斗提提升机. Each type has its own characteristics. For example, 斗提提升机 is a vertical – running 带式输送机,带式输送机 has a large conveying capacity and low power consumption but is difficult to move around bends, vibrating conveyors are simple and fast but prone to wear and blockage, and 螺旋输送机 is compact and has a strong conveying capacity but its components are easily worn. Pneumatic conveying equipment, on the other hand, uses air pressure to transport sand in closed pipes. It has the advantages of reducing dust emissions, flexible pipeline layout, and the ability to achieve multi – point unloading. However, it is not suitable for transporting 块状物.

| Conveying Equipment Type | Characteristics | Advantages | Disadvantages |

|---|---|---|---|

| Mechanical Conveying Equipment – Bucket Elevator | Vertical running 带式输送机 | Simple structure for vertical transportation | Limited in horizontal transportation range |

| Mechanical Conveying Equipment – Belt Conveyor | Large conveying capacity, simple structure, long – distance transportation, low power consumption | Ideal for large – scale sand transportation over long distances | Difficult to bend, high maintenance requirements |

| Mechanical Conveying Equipment – Vibrating Conveyor | Simple structure, fast conveying speed | Quick transfer of sand in short – distance applications | Prone to wear, easy to block, noisy |

| Mechanical Conveying Equipment – Screw Conveyor | Compact structure, strong conveying capacity, stable operation | Suitable for transporting sand in a confined space | Components are easily worn, materials are prone to blockage |

| Pneumatic Conveying Equipment | Closed – pipe transportation, reduces dust, flexible pipeline layout, multi – point unloading | Environmentally friendly, space – saving, flexible in layout | Not suitable for transporting 块状物 |

4. Advantages of 3D Printing in Foundries

4.1 Improved Casting Quality

The use of 3D printing technology in foundries allows for better control over the mold and core geometry. This results in more accurate castings with fewer defects. The uniform sand quality provided by the sand treatment system also contributes to improved casting quality. For example, the regenerated sand with a consistent particle size and low dust content helps to prevent porosity and other casting defects.

4.2 Cost – Savings

Although the initial investment in 3D printing equipment and sand treatment systems may be high, in the long run, it can lead to significant cost – savings. The ability to produce small batches without the need for expensive tooling reduces production costs. Additionally, the recycling and regeneration of sand lower the consumption of new sand and binder, further cutting down costs.

4.3 Environmental Benefits

3D printing foundries with efficient sand treatment systems have a lower environmental impact. The reduced consumption of new sand and the recycling of used sand help to conserve natural resources. The closed – loop sand treatment process also minimizes waste, and the use of pneumatic conveying equipment reduces dust emissions, making the foundry more environmentally friendly.

5. Challenges in 3D Printing Foundries and Sand Treatment Systems

5.1 High Initial Investment

The purchase of 3D printing equipment, sand treatment machines, and related software requires a substantial amount of capital. This high initial investment can be a barrier for small and medium – sized foundries, limiting their ability to adopt this technology.

5.2 Technical Complexity

The operation and maintenance of 3D printing equipment and sand treatment systems require a high level of technical expertise. The complex processes involved, such as the 3D printing process itself, the control of sand quality, and the operation of advanced equipment, pose challenges for foundry workers who may be unfamiliar with this technology.

5.3 Quality Control

Ensuring consistent quality in 3D – printed castings can be difficult. Variations in sand quality, printer performance, and post – processing can all affect the final casting quality. The sand treatment system needs to be carefully monitored and controlled to maintain the quality of the sand, which is crucial for achieving high – quality castings.

6. Future Outlook

6.1 Technological Advancements

In the future, we can expect to see further technological advancements in 3D printing and sand treatment systems. New materials and binders will be developed to improve the performance of the sand molds and cores. The efficiency and accuracy of 3D printers will also increase, and the sand treatment equipment will become more automated and intelligent, reducing the need for manual intervention.

6.2 Industry Integration

The 3D printing foundry industry is likely to integrate more closely with other industries. For example, the combination of 3D printing with the Internet of Things (IoT) will enable real – time monitoring and control of the sand treatment system and the casting process. This will improve production efficiency and quality control.

6.3 Market Expansion

As the technology matures and the cost of 3D printing and sand treatment systems decreases, the market for 3D printing foundries is expected to expand. More industries, such as aerospace, automotive, and medical, will adopt this technology to produce high – quality, complex castings.

7. Conclusion

3D printing technology has brought about a significant transformation in the foundry industry. The sand treatment system in 3D printing smart foundries is a critical component that ensures the quality of the sand used in the casting process. By understanding the 工艺流程 and key equipment of the sand treatment system, foundries can make the most of this technology. Although there are challenges associated with 3D printing in foundries, the advantages in terms of casting quality, cost – savings, and environmental benefits make it a promising technology for the future. With continuous technological advancements and industry integration, 3D printing foundries are expected to play an increasingly important role in the global manufacturing industry.