Casting shrinkage is a common challenge encountered in metal casting processes, which can lead to dimensional variations and defects in the final castings. Foundry operators need to have a thorough understanding of casting shrinkage and implement practical guidelines to address this issue effectively. This article provides practical guidelines for foundry operators to tackle casting shrinkage and ensure the production of high-quality castings.

- Material Selection: Opt for materials with lower shrinkage tendencies, such as alloys with lower solidification shrinkage or modified compositions that minimize shrinkage defects. Consult with material suppliers and engineers to select the most suitable material for the casting application, considering both mechanical properties and shrinkage characteristics.

- Pattern Design: Pay careful attention to pattern design to account for the expected shrinkage during solidification. Incorporate appropriate allowances and dimensional compensations in the pattern to compensate for the shrinkage. Ensure that the pattern is properly vented to allow the escape of air and gases that could contribute to shrinkage defects.

- Mold Design: Optimize mold design to promote uniform cooling and minimize thermal gradients, which can exacerbate shrinkage-related dimensional variations. Consider factors such as mold material, gating system design, and riser placement. Ensure that the mold cavity is properly vented to facilitate the escape of gases and minimize the risk of shrinkage defects.

- Pouring and Solidification Control: Pay close attention to pouring and solidification control to minimize shrinkage defects. Maintain proper pouring temperature and avoid temperature differentials that can lead to uneven solidification. Employ techniques such as directional solidification and controlled cooling to manage shrinkage behavior and ensure uniform solidification throughout the casting.

- Riser Design: Optimize riser design to provide adequate feeding and compensate for shrinkage. Properly designed and placed risers can help supply additional molten metal to compensate for the volume reduction during solidification. Consider the size, shape, and placement of risers to ensure effective feeding and minimize shrinkage defects.

- Heat Treatment: Utilize appropriate heat treatment processes to relieve residual stresses and minimize the risk of shrinkage-related defects. Stress relieving and annealing processes can help mitigate the effects of residual stresses induced during solidification, reducing the likelihood of shrinkage-related cracking or distortion.

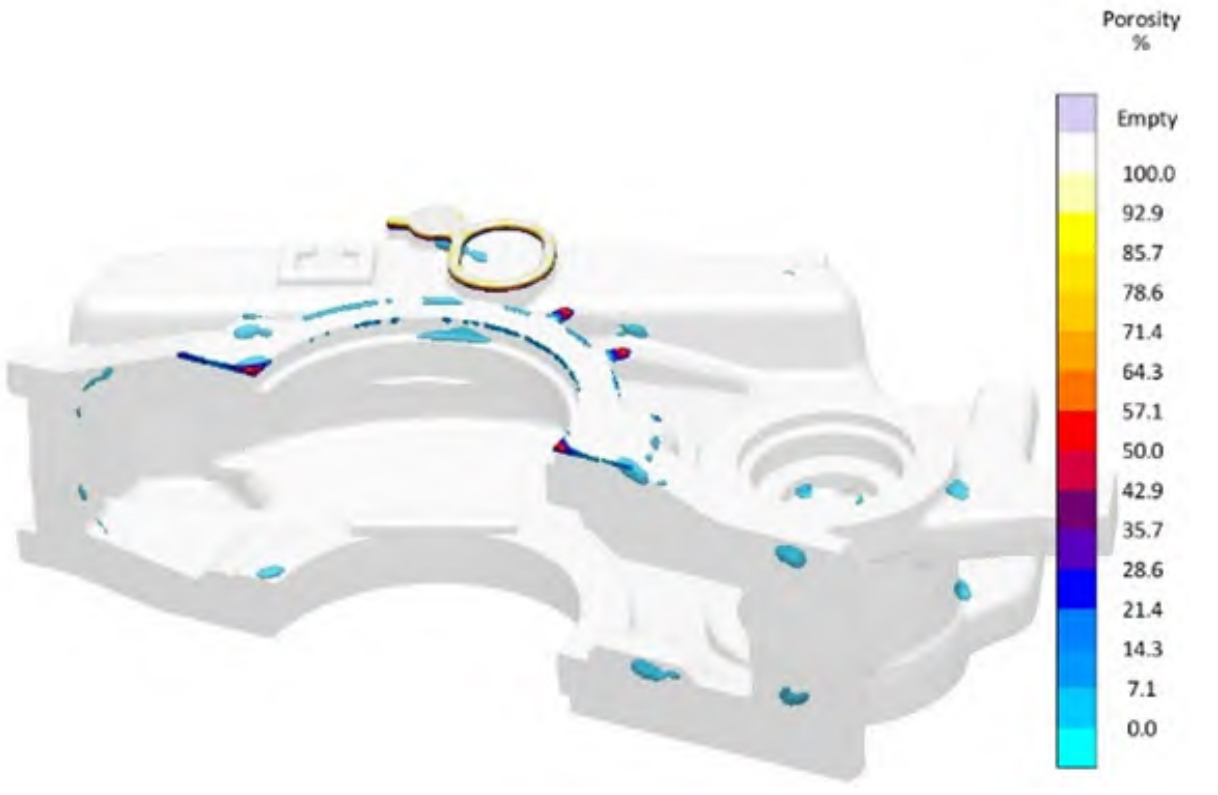

- Process Monitoring and Quality Control: Implement robust process monitoring and quality control measures to detect and address shrinkage defects promptly. Utilize non-destructive testing techniques, such as X-ray or ultrasound, to identify internal shrinkage defects. Conduct dimensional inspections to ensure that the castings meet the specified tolerances and address any deviations early in the process.

- Continuous Improvement: Emphasize continuous improvement by analyzing casting defects, identifying root causes, and implementing corrective actions. Regularly review and analyze casting performance data to identify trends and areas for improvement. Encourage collaboration among operators, engineers, and quality personnel to develop innovative solutions for minimizing shrinkage defects.

By following these practical guidelines, foundry operators can effectively address casting shrinkage issues and produce high-quality castings. Attention to material selection, pattern and mold design, pouring and solidification control, riser design, heat treatment, and process monitoring is crucial for mitigating shrinkage defects. Continuous improvement efforts and a proactive approach to quality control will help ensure ongoing success in tackling casting shrinkage challenges.