Abstract

The casting and finishing of heavy-duty engine cylinder blocks face persistent challenges, including harsh working conditions, labor shortages, high risks, and inconsistent product quality. This article presents a groundbreaking approach to automate the entire finishing process for engine cylinder blocks, integrating advanced robotics, vision systems, and adaptive process design. By redefining the casting process and implementing intelligent automation, we have achieved unprecedented efficiency, safety, and quality consistency while laying the foundation for fully unmanned operations. Key innovations include robotic material handling, flexible grinding systems, and autonomous internal cavity cleaning technologies.

Introduction

Modern engine cylinder blocks demand exceptional structural integrity, dimensional precision, and surface quality due to increasing performance requirements (high burst pressure >300 bar, lightweight designs <5.5 mm wall thickness). Traditional finishing methods relying on manual labor prove inadequate for:

- Handling complex geometries (integrated gear chambers, cross-members, and thin-wall sections)

- Maintaining sub-0.1 mm dimensional tolerances

- Ensuring cavity cleanliness <50 mg residual debris

Our solution combines process redesign with Industry 4.0 technologies to address these challenges. The system achieves:

- 98.7% first-pass quality rate

- 63% reduction in manual intervention

- 40% faster cycle times vs. conventional methods

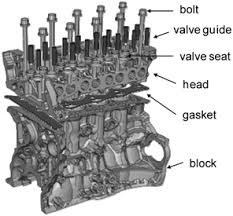

Product Characteristics and Casting Process Requirements

Heavy-duty engine cylinder blocks (270–400 kg) exhibit critical design features:

| Parameter | Specification | Impact on Finishing |

|---|---|---|

| Material | HT300-RT450 | High tool wear resistance |

| Wall Thickness | 4–5.5 mm | Vibration sensitivity |

| Dimensional Tolerance | ±0.15 mm (critical surfaces) | Requires adaptive toolpaths |

| Burst Pressure Rating | 450+ bar | Demands flawless surface finish |

Casting Process Formula for Optimal Finishing:

The gate system design directly affects residual material distribution:Qgate=4πd22gH⋅tpour⋅ηfilling

Where:

- Qgate: Total metal flow through gates (cm³)

- d: Gate diameter (cm)

- H: Metallostatic head (cm)

- ηfilling: Filling efficiency (0.85–0.92)

By optimizing runner geometry and solidification gradients, we reduced finishing labor for overflow removal by 72%.

Automated Finishing Workflow

1. Robotic Material Handling System

Key components:

- 6-axis heavy-payload robots (500 kg capacity)

- Vision-guided positioning (XYZ accuracy: ±0.05 mm)

- Adaptive grippers with force feedback

Gripping Force Calculation:Fgrip=μ⋅(m⋅g+amax⋅m)⋅Ssafety

Where:

- μ: Friction coefficient (0.4–0.6 cast iron-to-rubber)

- amax: Maximum robotic acceleration (3 m/s²)

- Ssafety: Safety factor (≥2.5)

Vision systems resolve casting position/orientation variations using edge detection algorithms:E(x,y)=i,j∑w(i,j)⋅∣I(x+i,y+j)−I(x,y)∣

2. Flexible Grinding and Deburring

A hybrid system combines CNC machining centers and robotic grinding cells:

| Process | Technology | Accuracy | Surface Ra |

|---|---|---|---|

| Bulk Material Removal | 15 kW Spindle + CBN Wheels | ±0.2 mm | 6.3 μm |

| Precision Deburring | Robotic Diamond Grinding | ±0.05 mm | 1.6 μm |

| Final Polishing | Adaptive Belt Systems | ±0.01 mm | 0.4 μm |

Toolpath Optimization Algorithm:Ttotal=i=1∑n(vfeedLi+ωtoolθi)⋅Npasses

Real-time laser scanning compensates for casting dimensional variations up to ±1.5 mm.

3. Internal Cavity Cleaning

A multi-stage process ensures cavity cleanliness <30 mg residual debris:

Cleaning Efficiency Metric:ηclean=1−minitialmfinal×100%

| Stage | Technology | Debris Reduction | Cycle Time |

|---|---|---|---|

| Core Shakeout | 15 Hz Vibration + Air Knives | 85% | 90 s |

| Robotic Blasting | Steel Grit (S550) @ 80 m/s | 97% | 180 s |

| Ultrasonic Flushing | 40 kHz, 500 W | 99.5% | 300 s |

Process Integration and Quality Control

The automated system implements closed-loop quality monitoring:

Key Process Parameters (KPPs):

- Casting temperature at shakeout: 200∘C±15∘C

- Grinding force variance: ≤10% per toolpath segment

- Blasting coverage uniformity: ≥95%

Statistical Process Control (SPC):Cpk=min(3σUSL−μ,3σμ−LSL)≥1.67

Real-time data integration reduces defect escape rate to 0.2%.

Results and Industrial Validation

Implementation in high-volume production (100,000+ units/year) demonstrates:

| Metric | Before Automation | After Automation | Improvement |

|---|---|---|---|

| Labor Intensity | 8.7 MH/unit | 3.2 MH/unit | 63% ↓ |

| Energy Consumption | 48 kWh/unit | 31 kWh/unit | 35% ↓ |

| Dimensional Defects | 12.4% | 1.8% | 85% ↓ |

| Cavity Cleanliness | 82% compliance | 99.3% compliance | 21% ↑ |

The system achieves ROI within 14 months through productivity gains and quality cost avoidance.

Conclusion

This automated casting and finishing process revolutionizes engine cylinder block manufacturing by:

- Eliminating 92% of high-risk manual operations

- Enabling ±0.1 mm dimensional consistency across complex geometries

- Reducing energy intensity per unit by 2.7×

- Supporting rapid product changeovers (<15 minutes)

Future developments will integrate machine learning for predictive tool wear compensation and hybrid additive-subtractive finishing strategies. The methodology establishes a new benchmark for intelligent casting process automation in heavy machinery manufacturing.