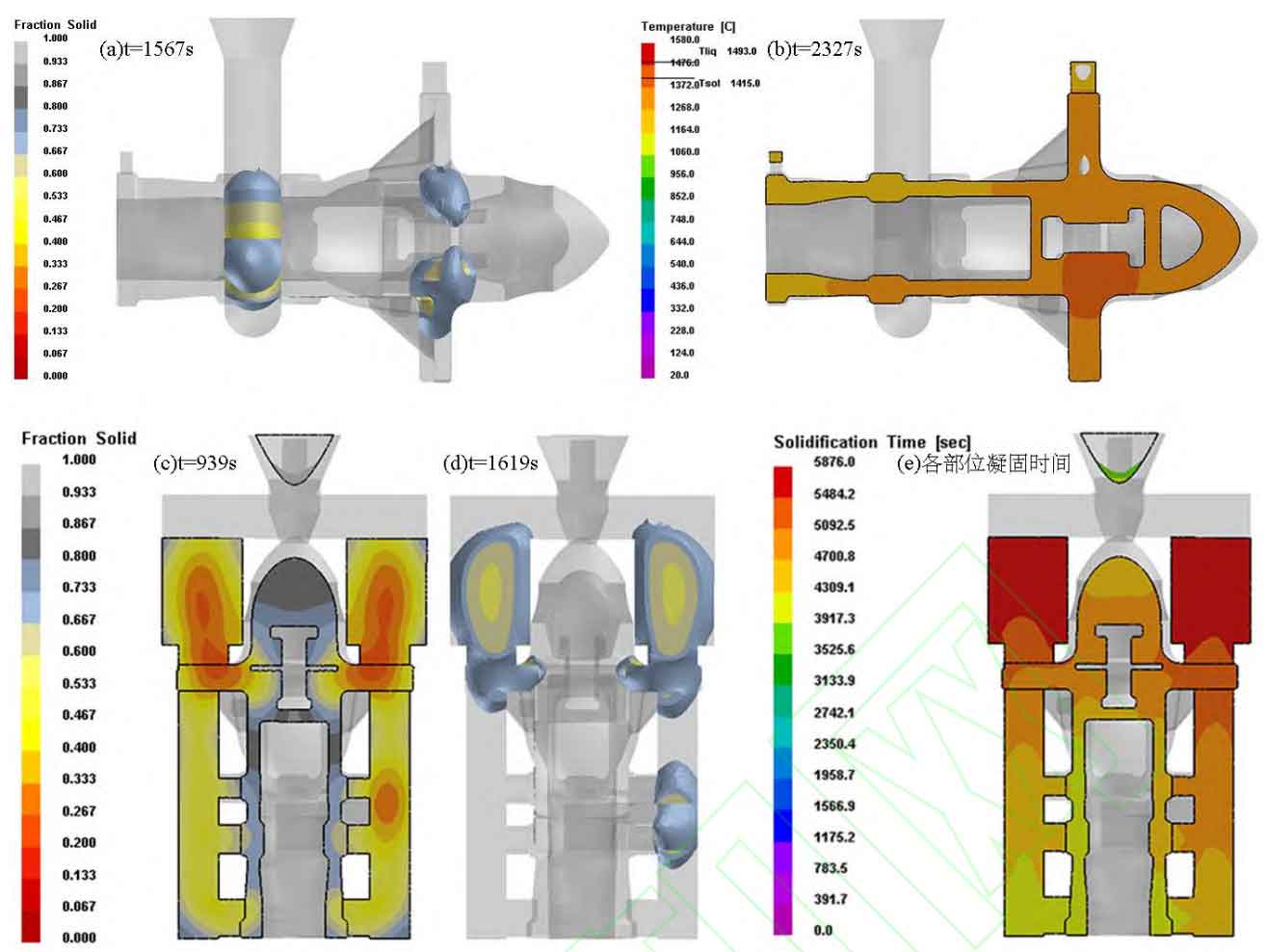

In the solidification process of investment casting, the appearance, thin shoulder and thin-wall area of investment casting in scheme a solidifies first, and the thick and large part in the middle solidifies finally, which fails to realize sequential solidification and simultaneous solidification, as shown in Fig. 1 (a) ~ (b). It can be seen from Figure 1 (a) that at the end of the solidification process, a large isolated liquid phase area appears at the top of the investment casting and the intersection of the hook tongue and the hook head. Fig. 1 (b) is the schematic diagram of YZ direction slice at the end of solidification of investment casting. It can be seen that the temperature at the lower part of the intersection of hook head and hook tongue is the highest. After solidification of other parts, the area is still in the solid-liquid two-phase area, and there is no shrinkage after solidification; At the same time, the temperature difference between thin-walled and thick areas is large, which will lead to serious thermal stress.

The solidification simulation results of scheme B show that there are no insufficient pouring and cold shut defects after mold filling, as shown in Fig. 1 (c) ~ (E). Fig. 1 (c) is the schematic diagram of YZ direction temperature slice at the end of solidification of investment castings. It can be seen that the temperature of the casting body during solidification of investment castings is lower than that of the gating system, which will be conducive to the feeding effect of metal liquid in the gating system on investment castings. Because the sprue is connected with the large shoulder of the investment casting and the cross-sectional area of the sprue is increased, there is no isolated liquid phase area at the connection between the hook head and the hook tongue of the investment casting during solidification. The important parts of the investment casting solidify first, and the gating system can continuously provide feeding. The final solidification area is shown in Figure 1 (d). According to figure 1 (E), the solidification time of the whole hook head and plane connection area of investment casting is basically the same, which is earlier than that of the gating system.

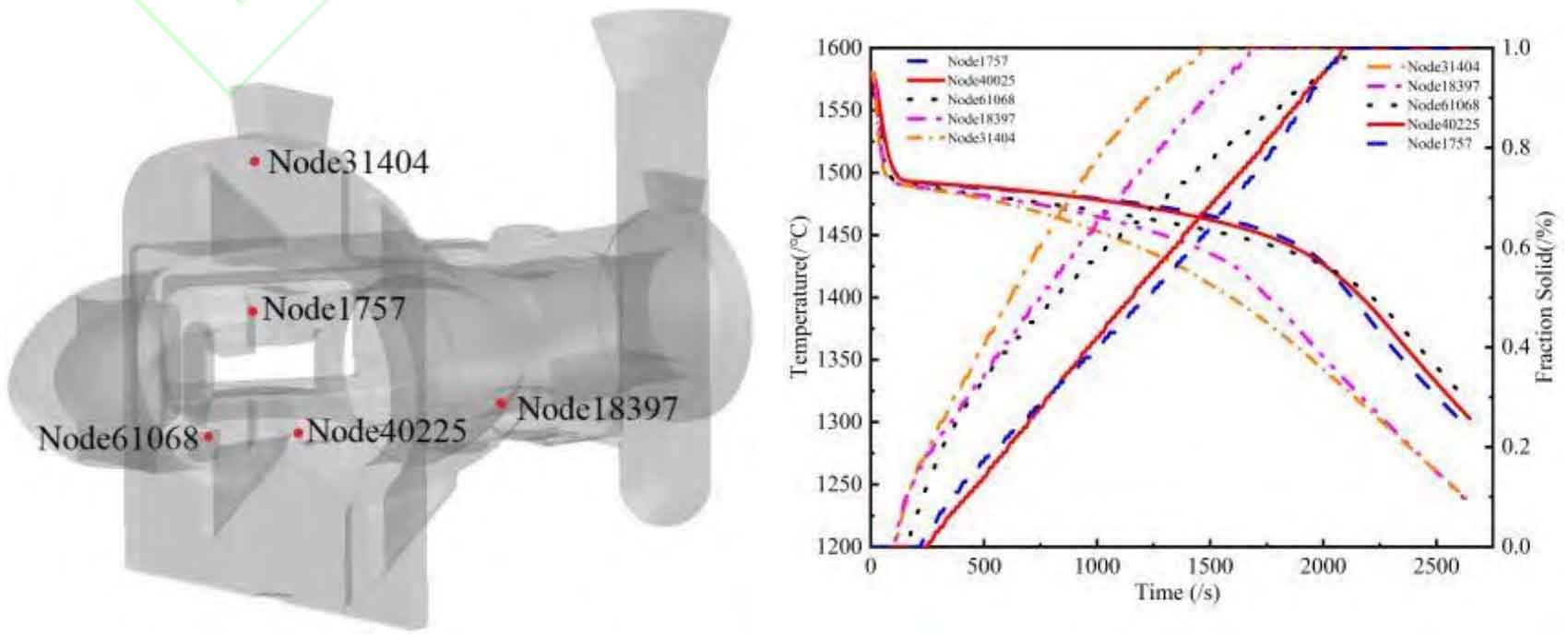

In order to further reveal the defect formation process of investment casting, the solidification process at the characteristic position node of investment casting is selected for observation and analysis, and the results are shown in Fig. 2. The changes of node temperature and solid fraction at different positions of investment casting with time are shown in Figure 2 (b). It can be seen from the figure that the temperature of node 31404 at the thin-wall part begins to drop first and the solid region begins to form first, resulting in the closure of riser feeding channel and the loss of riser feeding function. The node 18397 located near the gate followed by the temperature drop and solidified in the thick part of the investment casting at the far end of the gating system. As node 18397 solidifies first, the feeding channel of the gating system is closed, which can not provide continuous feeding for the subsequent solidification process, which leads to insufficient solidification feeding in thick parts to a great extent, and greatly increases the probability of shrinkage cavities and defects.

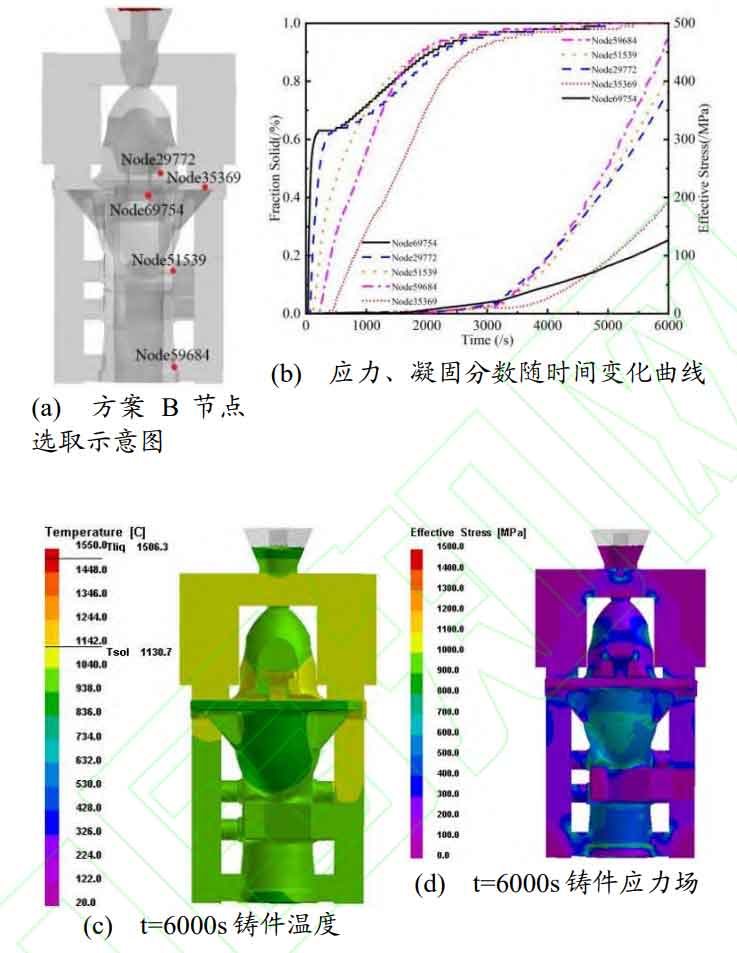

Analyze the stress change process of different parts of investment casting during cooling in scheme B, and select the characteristic position nodes of investment casting for observation and analysis, as shown in Fig. 3. It can be seen that the internal node node 69754 of the knuckle begins to solidify first and solidifies rapidly. Then it converges with node 29772, node 51539 and node 59684, and the solidification rate decreases. When the bottom node node 59684 is t = 6000s, that is, when it is below 938 ℃ in Figure 3 (C), the stress value reaches the maximum value of 470mpa. Node 29772 at the joint between the hook head and the hook tongue has a rapid solidification rate in the early stage and a decrease in the later stage. It basically solidifies when t = 3000s, and its stress value is 370mpa. Node 35369 at the shoulder gate basically solidified at t = 3500s, and this node solidified the slowest, which was caused by the influence of the thick sprue near the shoulder; When the joint stress of the casting reaches the lowest value of 539 s in the middle gate (Fig. 3), the average joint stress is 6000s.

It can be seen from Figure 3 (c) that at 6000s, the overall temperature of investment casting has fallen below the liquidus temperature, most of which are about 800 ℃. Only the connection temperature between the hook head and the hook tongue is slightly higher, which is about 1000 ℃, and the abdominal temperature is the lowest. It can be seen that through the optimization of gating system, the stability of mold filling process is ensured, the sequential solidification is basically realized, and the holes and cracks in key parts are eliminated.

According to the comparison of the above simulation results of the temperature field and stress field in the solidification process of the two schemes, the insufficient feeding of the key parts and thick parts of the investment casting in the solidification process of the investment casting in scheme a will cause a large tendency of shrinkage cavity and porosity; In scheme B, because the volume of the gating system is large enough and the number of gates is large enough, the whole investment casting can be fed during solidification, which ensures sequential solidification and reduces the tendency of shrinkage cavity and porosity of investment casting.