Analysis of casting difficulties

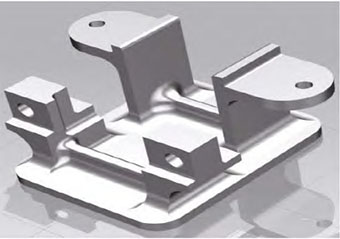

To ensure the non-destructive testing and dimensional qualification of castings, and meet production needs, the casting process of the pull rod seat is improved to increase the first pass rate of castings. Firstly, by analyzing the shrinkage deformation of castings and the related effects of frame welding on the dimensions of castings, the processing quantity of castings and the process correction quantity of some dimensions can be adjusted; The second is to adjust the process plan based on the requirements of the inspection position and inspection level, calculate the position and size of the sprue and riser, and ensure the feasibility of improving the process through solidification simulation analysis and production verification. The requirements for non-destructive testing of pull rod seat castings are high, and there are significant differences in product wall thickness. There are multiple isolated hot spots such as thick areas and large rounded corners, making it difficult to achieve sequential solidification; The product size requirements are strict, and castings are prone to deformation during processes such as filling solidification, normalizing pretreatment, quenching and tempering treatment, welding, and transportation. At the same time, the influence of frame deformation on relevant dimensions also needs to be considered.

(1) Considering that the testing location meets the testing requirements, while also taking into account the internal compactness of the castings at other hot joint locations.

(2) The machining allowance and anti deformation of castings should consider the influence of frame deformation.

(3) The tolerance of the inner dimensions of the casting is -2~+1 mm. When designing the process, multiple factors need to be considered to ensure that the dimensions meet the requirements after welding.

Optimization of Casting Process

(1) Adjust the casting parting surface and the position of the riser. The riser should be located at the position of the flaw detection rod, and the square rod should be supplemented. Cold iron should be added to the corner of the bottom plate to enhance the quenching at this position and ensure internal quality.

(2) According to the shrinkage of the casting and the feedback of the frame after welding, adjust the size of the square pull rod from 51mm to 45mm to ensure the overall processing needs of the frame after welding; Adjust the height from 131 mm to 140 mm, which is guaranteed by machining; R45 mm radius size and thickness correction of 2 mm.

(3) The 120mm span and 130mm position remain unchanged. Due to the thin wall thickness, deformation may occur during cleaning, heat treatment, and transportation. Therefore, a tie bar is added to this position and removed after quenching and tempering. At the same time, the span reduction is adjusted to 1% based on the effect of the tie bar.

The solidification simulation of the original process method shows that although the original process can ensure the compactness of the bottom plate and rounded corners, there are shrinkage defects in the required inspection positions. The simulation results are consistent with the actual inspection results of the casting in terms of position and size. By conducting solidification simulation analysis on the optimized process plan and analyzing the temperature field and shrinkage simulation results, it can be seen that the casting solidifies sequentially from thin wall to thick wall and from casting to riser, basically achieving the expected temperature gradient field design. Defect prediction from the solidification simulation results shows that the casting The shrinkage and loosening defects at the required location for flaw detection have been eliminated.

The optimized process was used for production verification, and the experimental products were subjected to ultrasonic flaw detection. No defects exceeding the standard were found inside the castings. The actual production of the castings was consistent with the simulation analysis and prediction results. Shrinkage and porosity casting defects were solved, and the quality of the castings was greatly improved. Three dimensional dimension inspection shall be carried out for the produced blanks. All dimensions of the castings shall meet the requirements of the drawings. The dimensions with problems in the original process shall be measured with emphasis, especially for the 120 mm span after heat treatment, quenching and tempering, and removal of tie bars. The marking processing results of the bogie after welding show no size and quality problems.

The improvement of the casting process for locomotive pull rod seats is achieved by combining theoretical calculations, numerical simulations, and production verification to pre evaluate the casting quality. This not only saves time for product trial production and development, but also improves the quality of product development. The improvement process of casting technology fully considers the quality hazards in subsequent links, which can effectively prevent unqualified products from flowing into the next process, improve production efficiency, and reduce manufacturing costs.

(1) By conducting solidification simulation analysis on the process plan before and after improvement, and comparing it with the actual production inspection results, the casting defects of shrinkage porosity and shrinkage cavity that occurred during the production process of the pull rod seat were effectively solved.

(2) By controlling the process size, adjusting the amount and setting the tension bars, the casting size is effectively ensured and deformation during the production process is prevented. (3) When designing the process, full consideration is given to the product’s usage requirements and flaw detection requirements, avoiding the shortcomings of avoiding the heavy and focusing on the light in the process design.

(4) The optimization of casting process through numerical simulation has a shorter cycle and saves manufacturing costs compared to traditional design methods.