ZHY casting assisted in the development of a new 16 l natural gas engine. The cylinder block is one of the key parts of the engine. The cylinder block casting has complex structure and high dimensional accuracy requirements. At the same time, in order to meet the requirements of automobile lightweight, the requirements of wall thickness and dimensional accuracy of cylinder block casting will be further improved, which increases the difficulty of cylinder block casting process and production.

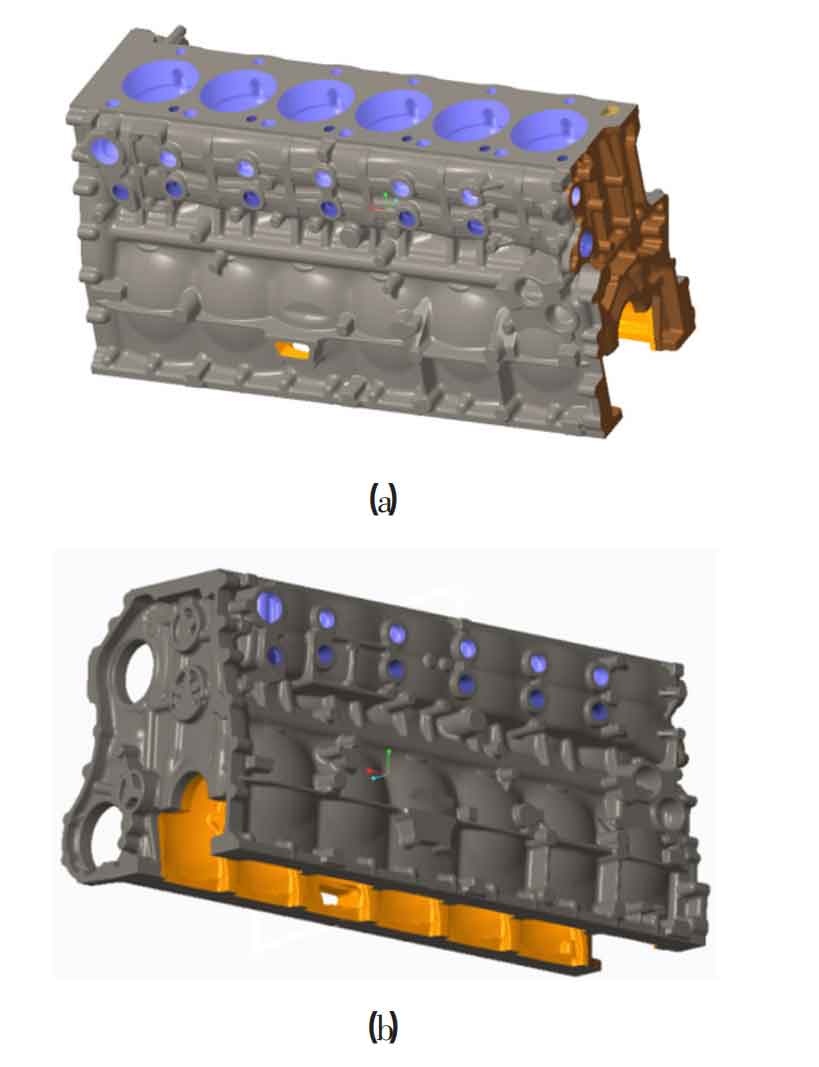

The overall dimension of cylinder block casting is 1 040.5 mm × 585.5mm × 568.5 mm, the mass of cylinder block casting is 370 kg, and the structure of cylinder block casting is shown in Figure 1. The general wall thickness of cylinder block castings is (5.0 ± 0.5) mm, the machining allowance of cylinder block castings is required to be 3.5 ~ 5.0 mm, and the other dimensions meet the requirements of CT10 in GB / T 6414-1999 dimensional tolerances and machining allowance of castings. The material grade is HT250. The cylinder block casting body is required to take samples, with tensile strength of 240 ~ 280 MPa and hardness of 180 ~ 240 Hb.

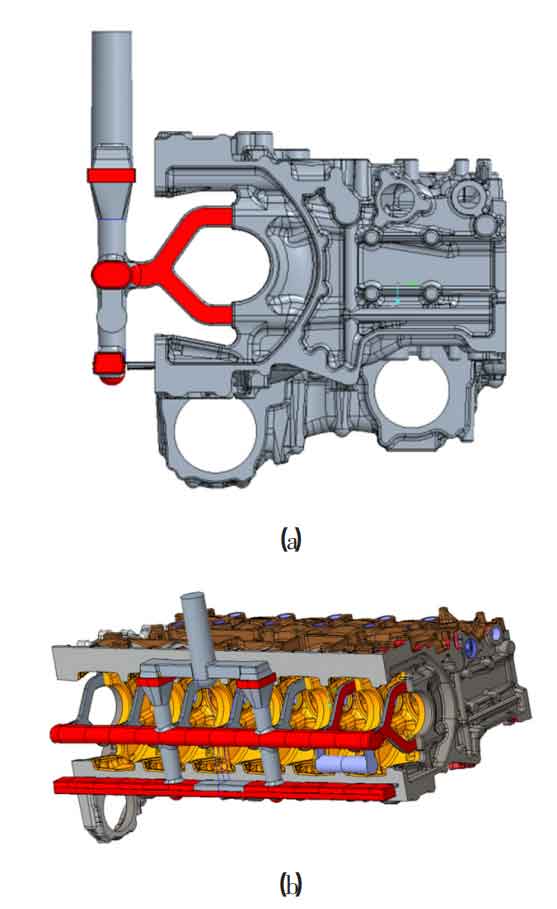

A total of 12 sand cores are required for cylinder block castings. Plastic molds and self hardening sand are used for manual molding and core making. The stepped gating system is adopted (as shown in Figure 2), the pouring temperature is 1420 ~ 1440 ℃, and the pouring time is 24 ~ 28 s.

The trial production was carried out according to the improved process, and there was no crack defect in the cylinder block casting. In the process of mass production of cylinder block castings, there were no cracks, which verified the effectiveness of the measures.

In the process of cylinder block casting design, on the premise of ensuring strength and stiffness, strive to reduce wall thickness and mass. Therefore, there is uneven wall thickness in the structure of cylinder block casting, and the cooling speed of each part varies greatly, so the internal stress of cylinder block casting is inevitable. Through comprehensive analysis, the structure of cylinder block casting is optimized to avoid stress concentration, increase the structural strength at the stress of cylinder block casting, improve the yielding or collapsibility of core, reduce the shrinkage resistance of cylinder block casting, reduce the shrinkage tendency of materials, reduce the internal stress of cylinder block casting, and solve the problem of crack defects of cylinder block.