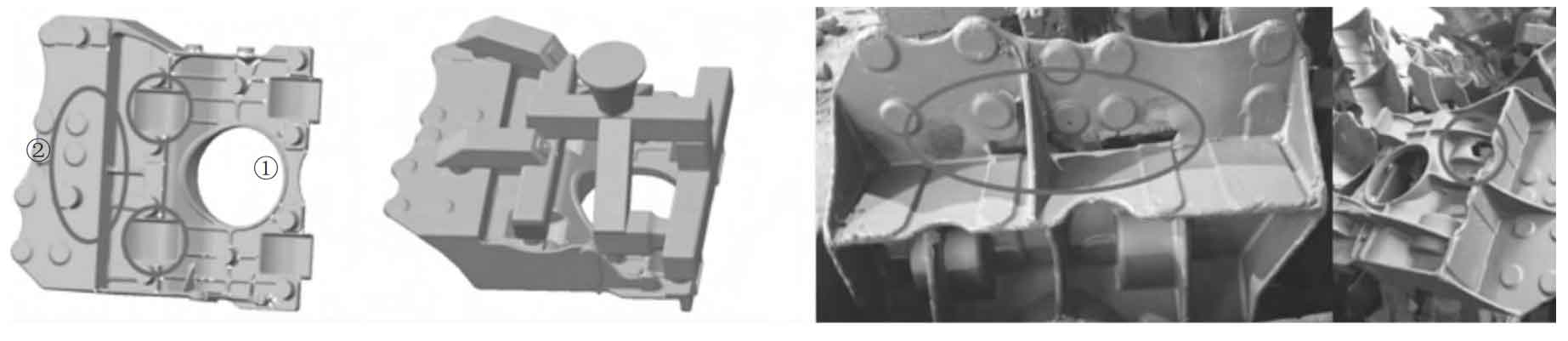

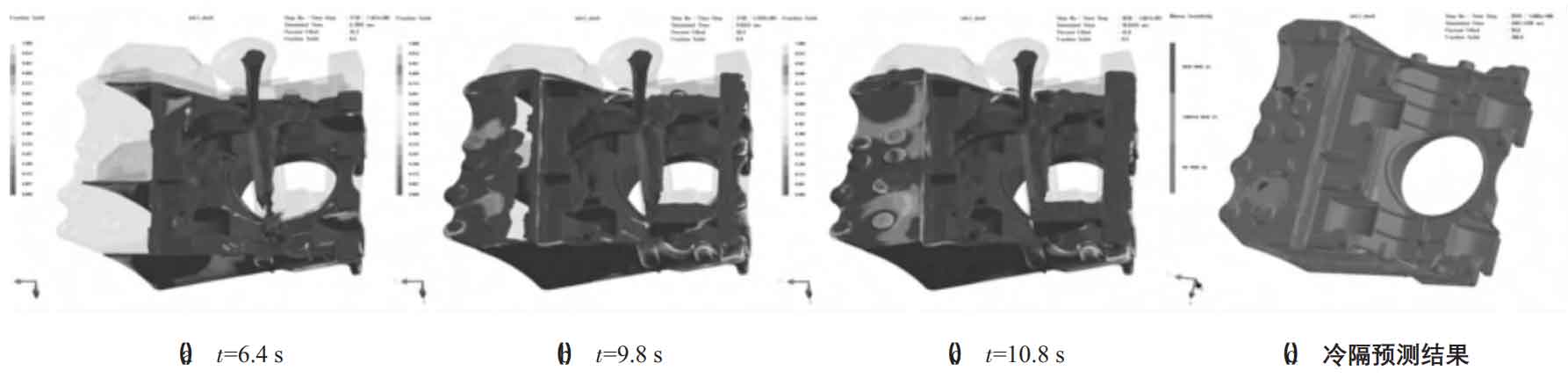

Another investment casting thin-walled steel casting of ZHY casting was under poured in the trial production process, and the defects were more than 90% and concentrated. The product structure is shown in Figure 1a, and the process scheme is shown in Figure 1b. The insufficient pouring defects are mainly concentrated in the parts “①” and “②” marked in Figure 1a, of which “①” is the part with the minimum wall thickness. Physical defects are shown in Figure 1C. Overall dimension of the product: 540 mm × 520 mm × 220 mm, average wall thickness 8 mm, minimum wall thickness 5 mm. Based on the above analysis experience of insufficient pouring defects, the defect scheme is analyzed by momentum coupling analysis method. The pouring temperature is set to 1580 ℃, and other parameters are the same as those in the table. The mold filling, solidification and cold lap prediction results are shown in Figure 2.

| Casting material | Shell material | Shell thickness / mm | Shell temperature / ℃ | Pouring temperature / ℃ | Pouring speed / (m · s-1) | Cooling mode | Heat transfer coefficient between casting and shell (/ w · m – · 2 K -) |

| C45E | Silica sand | 8 | 650 | 1540 | 0.38 | Air cooling | 900 |

It can be seen from Figure 2 that part “②” is finally filled. At 6.4 s of filling, the front edge of liquid metal filling has begun to solidify. At 9.8 s of filling, the liquid metal in both filling directions solidifies, and the solid fraction is about 20% ~ 30%. Therefore, the risk of insufficient pouring of part “②” is high. There is a certain difference between the insufficient pouring area of investment casting shown and the actual situation. From the analysis results, the main reason for the insufficient pouring defect of investment casting steel is the low pouring temperature. In addition, the design of pouring system and the placement position of mold shell lead to the final filling of part “②”, which is also the reason for insufficient pouring.

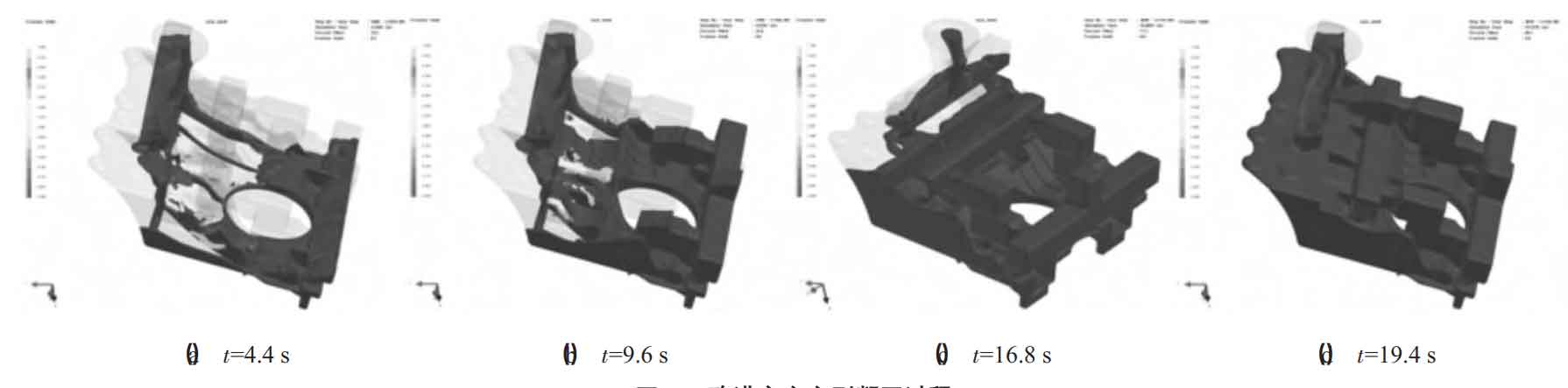

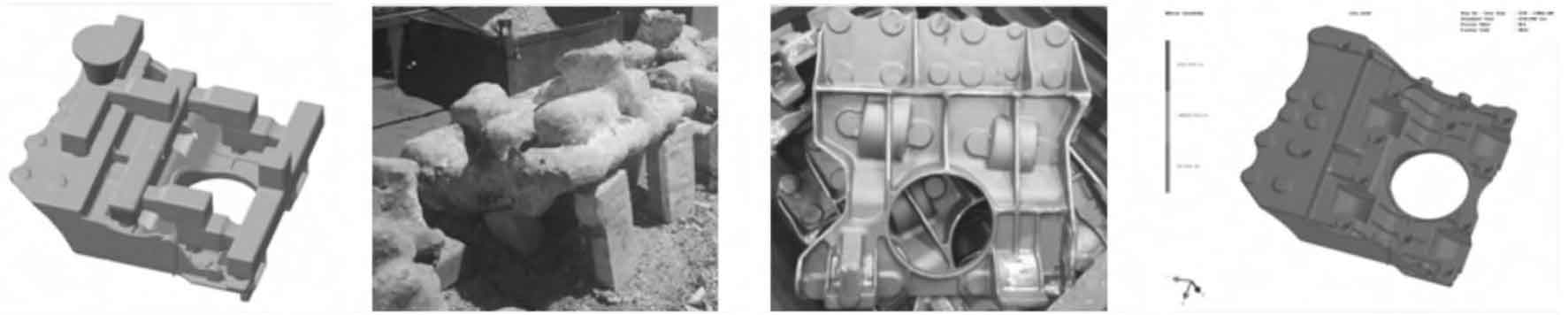

Therefore, the gating system is improved. The improvement scheme and cold shut prediction results are shown in Figure 3. In this paper, the improved scheme is analyzed by momentum coupling analysis method. The pouring temperature is set to 1600 ℃, and other parameters are the same as those in the table. The filling and solidification conditions are shown in Figure 4.

(c) Improvement scheme: casting material object (d) Cold trap prediction results

In the improved scheme, the molten metal is filled from the insufficient area of the original casting. In addition, when the mold shell is placed, one side of the gate cup is raised with a support. Compared with the original scheme, the filling head in most parts of the investment casting is increased and the filling capacity is enhanced. The physical pouring test shows that the insufficient pouring defect of investment casting can be eliminated. The results of mold filling and solidification process of investment casting steel show that there is no solidification before filling, and the investment casting steel is filled successively from the end of mold filling to one side of gate cup, without the risk of insufficient pouring. The cold lap prediction results show that the investment casting has no risk of insufficient pouring, which is consistent with the batch physical verification, and the insufficient pouring defect is eliminated.