The steel castings were trial produced in two batches, and the first time was qualified, and the second time there was shrinkage cavity and porosity defect. After investigating the five aspects of personnel, machines, materials, methods and links, since there are no abnormal changes, it is inferred that the cause of the defect is still a problem in the casting process design.

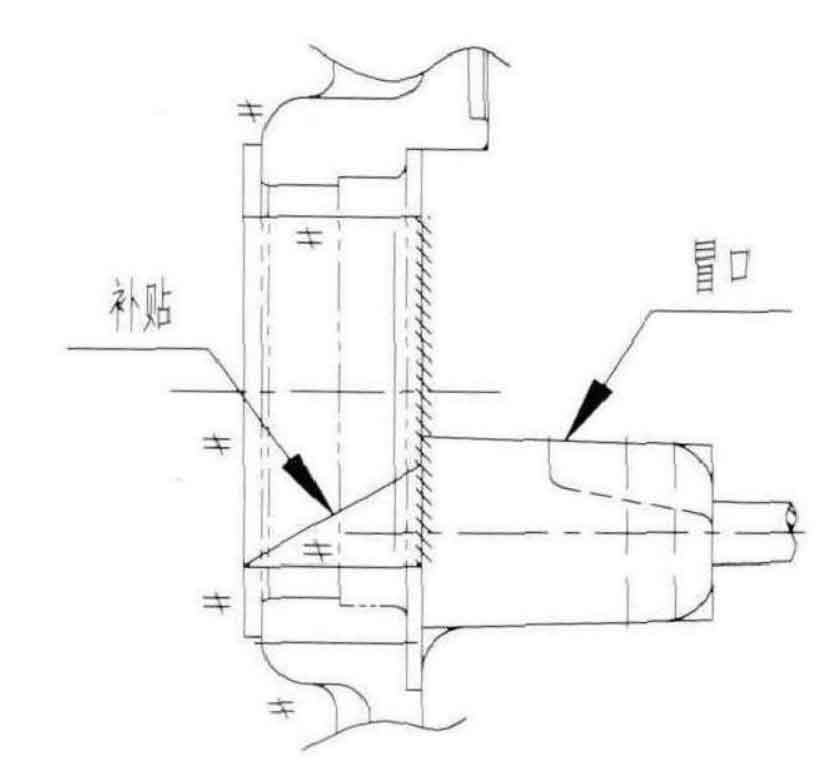

The local casting process diagram is shown in Figure 1. According to the modulus method, the modulus of the top riser for feeding this part is 1.34, while the modulus of the product itself is 1.22, and the riser modulus is 1.1 times of the product modulus, which meets the design requirements, but it is too conservative. The insufficient pressure head and the influence of melting, pouring and other factors may lead to shrinkage and porosity defects at the bottom of the riser.

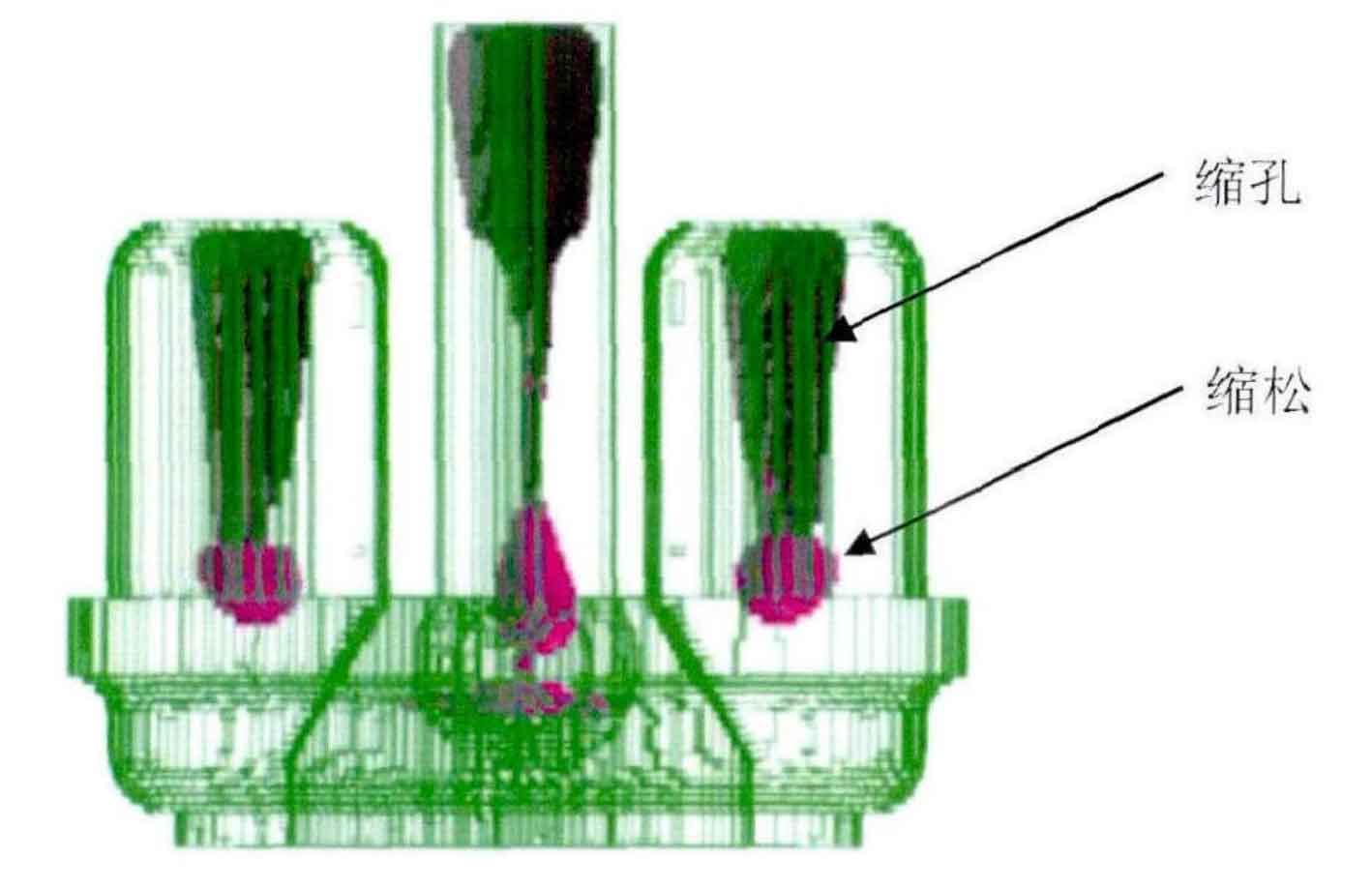

Then the local 3D dimensional simulation of the original process is carried out. The simulation results are shown in Figure 2. There is shrinkage porosity at the bottom of the riser, which extends to the surface of the steel casting. The simulation results are consistent with the actual situation of steel castings after machining.